Iidiski zetsimbi ezinobuncwane, ezibonakaliswe yi-pore yazo edibeneyo, ziye zavela njengezinto eziguqukayo ezinobuninzi bezicelo. Ezi diski, zenziwe ngesinyithi ezahlukahlukeneyo, zinika indibaniselwano eyodwa yeepropathi ezenza zibe yimfuneko kumashishini ahlukeneyo. Ukubaluleka kwabo kukukwazi ukugqwesa ekuhlungeni, ukusabalalisa ulwelo, kunye nokusabalalisa igesi, ngelixa begcina ukuqina okuphawulekayo kunye nokuzinza phantsi kweemeko ezinzima.

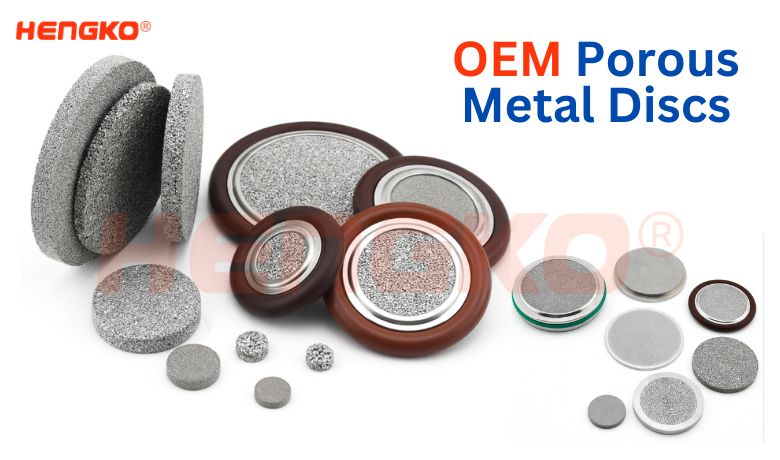

IiDiscs zeMetal ezinePorous: Ukukroba kwi-Versatility yazo

Iidiski zetsimbi ezinentunja zenziwe ngeendlela ezahlukeneyo, kubandakanywa ukuntywila, ukucofa, kunye ne-electrospinning. Ezi nkqubo zivumela ulawulo oluchanekileyo phezu kobungakanani bepore kunye nokusabalalisa, okwenza ukulungelelaniswa kweempawu zediski ukuze zihambelane nezicelo ezithile. I-porosity, ukusuka kwi-30% ukuya kwi-90%, inquma ukugqithiswa kwe-disc, ukuchaphazela amandla ayo okucoca okanye ukusabalalisa ulwelo kunye neegesi.

Uhlalutyo lokuthelekisa: Iidiski zeMetal ezinePorous ngokuchasene neMathiriyeli yeMveli

Ukuxabisa ngokwenene ukubaluleka kweediski zetsimbi ze-porous, masizithelekise kunye nezinto eziqhelekileyo ezisetyenziswa kumashishini ahlukeneyo.

Uhluzo

Kwindawo yokucoca, iidiski zetsimbi ezinamaqabunga zigqama ngokusebenza kwazo okuphezulu kunye nokuqina. Ubume bepore yabo entsonkothileyo ibamba ungcoliseko ngokuchaneka okumangalisayo, nakwinqanaba le-submicron. Ukongeza, ukuxhathisa kwabo kwi-corrosion kunye namaqondo obushushu aphezulu kubenza balungele imeko engqongileyo. Xa kuthelekiswa nephepha okanye izihluzi zepolymer, iidiski zetsimbi ezinamanzi zinika ubomi obude kakhulu kunye neendleko zokuyilungisa ezincitshisiweyo.

Ukuhanjiswa kolwelo

Iidiski zetsimbi ezinobuncwane zigqwesa kwizicelo zokusasazwa kwamanzi, ziqinisekisa ukuhamba okufanayo kunye nokuthintela umjelo. Ijometri yabo yepore elawulwayo ivumela ulawulo oluchanekileyo phezu kwesantya sokuhamba kunye nokusabalalisa uxinzelelo. Oku kubenza balungele ukusetyenziswa kwimichiza, kumayeza, kunye ne-aerospace, apho ukuhanjiswa kolwelo okungaguqukiyo kubalulekile. Izinto zemveli ezifana neepleyiti ezinemingxuma okanye iingcingo zocingo zihlala zisokola ukufikelela kwinqanaba elifanayo lokuchaneka kunye nokungaguquguquki.

Ukusasazwa kweGesi

Iidiski zetsimbi ezinamanzi zidlala indima ebalulekileyo ekusetyenzisweni kokusasazwa kwerhasi, iququzelela ukutshintshiselana ngerhasi okusebenzayo kunye nokukhuthaza ukusabela kweekhemikhali. I-porosity yabo ephezulu kunye nesakhiwo se-pore esidibeneyo sinciphisa ukuxhathisa ukusabalalisa, ukuvumela iigesi ukuba zingene kwi-disc ngokukhawuleza. Oku kubenza babe ngamalungu abalulekileyo kwiiseli zamafutha, iibhetri, kunye nezinzwa zerhasi, apho ukusasazwa kwerhasi kusebenza kakuhle. Iimathiriyeli zemveli ezifana neeseramics ezinamathambo okanye iifilimu zepolymer zihlala zibonisa ukunyanzeliswa kwerhasi esezantsi kunye nozinzo olulinganiselweyo phantsi koxinzelelo oluphezulu okanye iimeko zobushushu.

Ukuqukumbela: IiDiscs zeMetal ezinePorous – Isixhobo sexesha elizayo

Iidiski zetsimbi ezinamaqhekezabazimise ngokuqinileyo njengemathiriyeli ebalulekileyo, beguqula amashishini ahlukeneyo kunye nendibaniselwano eyodwa yeepropati. Ubuchule babo bokuhluza obuphezulu, ukusasazwa kolwelo olukhethekileyo, kunye nokusasazwa kwerhasi okusebenzayo kubenza babe yimfuneko kuluhlu olubanzi lwezicelo. Njengoko ukuqhubela phambili kwetekhnoloji kunye nosetyenziso olutsha luvela, iidiski zetsimbi ezinamaqhekeza zikulungele ukudlala indima ebaluleke ngakumbi ekubumbeni ikamva lobunjineli kunye nemveliso.

1. Ukuqonda iiPorous Metal Discs

1.1 INkcazelo yeePorous Metal Discs

Iidiski zetsimbi ezinobukroti ziyiklasi yezinto ezinobunjineli ezibonakaliswe kuthungelwano oludityanisiweyo lweepores. Ezi pores, ukusuka kubukhulu ukusuka kwi-micrometer ukuya kwi-millimeters, zivumela ukulawulwa kokuhamba kwamanzi kunye neegesi ngelixa zihluza ngokufanelekileyo izinto ezingcolileyo. Iidiski zentsimbi ezinamazinyo ziqhele ukwenziwa kwiintsimbi ezifana nentsimbi engatyiwayo, ubhedu, kunye nenikeli, zinika indibaniselwano yamandla, ukuqina, kunye nokumelana nomhlwa.

1.2 Iinkqubo zokuVeliswa kweeDiss zeNsimbi ezinembobo

Kusetyenziswa iindlela ezininzi ukwenza iidiskhi zetsimbi ezinentunjana, nganye ineengenelo zayo kunye nemida yayo. Iindlela zokuvelisa eziqhelekileyo ziquka:

1. Sintering: I-Sintering ibandakanya ukucinezela umgubo wesinyithi kwimilo efunekayo kwaye emva koko uyifudumeze kwiqondo lokushisa elingaphantsi kwendawo yokunyibilika. Le nkqubo ivumela iinqununu zetsimbi ukuba zidibanise kunye, zenze isakhiwo se-porous.

2. I-Etching: I-Etching ibandakanya ngokukhetha ukususa izinto kwi-substrate yentsimbi eqinileyo ukwenza iipores. Le ndlela inika ulawulo oluchanekileyo kubungakanani bepore kunye nokusabalalisa.

3. I-Electrospinning: I-Electrospinning isebenzisa indawo yombane ukuzoba imicu emihle kwisisombululo sepolymer. Le micu inokudityaniswa okanye idityaniswe kunye ukuze yenze idiskhi yentsimbi enemingxuma.

1.3 Izinto eziluncedo kwiPorous Metal Diss

Iidiski zetsimbi ezinamaqhekezazibonelela ngeenzuzo ezininzi ngaphezulu kwemathiriyeli yemveli njengephepha, ipholima, okanye izihluzi ze-ceramic:

1. UkuSebenza okuPhakamileyo koHlulo: Iidiski zetsimbi ezinobuncwane zingakwazi ukucoca ngokufanelekileyo ukungcola kwiisayizi ezincinci kakhulu, ukuya kumanqanaba e-submicron.

3. Ukusebenziseka kwakhona kunye nokuZinza: Iidiski zetsimbi ezinobuncwane zingacocwa kwaye zisetyenziswe kwakhona ngamaxesha amaninzi, ukunciphisa impembelelo yokusingqongileyo.

4. I-Versatility kunye ne-Customization: Iidiski zetsimbi ezinobuncwane zingenziwa ngokwezifiso ngokumalunga nobukhulu be-pore, i-porosity, kunye nokwakhiwa kwezinto eziphathekayo ukuze zihambelane nezicelo ezithile.

5. I-Biocompatibility: Iidiski ezithile zetsimbi ezinobuncwane zi-biocompatible, zizenza zilungele izicelo zonyango kunye neyeza.

2. Zingaphi Iindidi zeeDiskhi zeMetal zePorous?

Iidiski zetsimbi ezinamaqhekeza zihlelwa ngokobungakanani bepore, i-porosity, kunye nokwakheka kwezinto. Nazi ezinye zeentlobo eziqhelekileyo:

1. I-Sintered Porous Metal Discs:

Ezi diski zenziwe nge-sintering metal powder kwiqondo lokushisa eliphezulu.

Iidiski ezibangelwayo zinobukhulu obufanayo bepore kunye nokusabalalisa, ukubenza

ilungele izicelo zokuhluza.

2. IiDiskhi zeMetal eziQongiweyo:

Ezi diski zenziwa ngokudibanisa ipateni ibe yintsimbi eqinileyo.

Le ndlela ivumela ulawulo oluchanekileyo phezu kobungakanani bepore kunye nokumila,

ukubenza bafanelekele izicelo apho kufuneka ukuchaneka okuphezulu.

3. I-Electrospun Porous Metal Diss:

Ezi diski zenziwe nge-electrospinning isisombululo se-nanoparticles yensimbi kwi-substrate.

Iidiski ezibangelwayo zine-porosity ephezulu kakhulu kunye ne-random pore structure, ezenza zifaneleke

kwizicelo apho ukusasazwa kwerhasi kubalulekile.

4. IiDiskhi zeMetal eziHlehliweyo:

Ezi diski zine-gradient yobungakanani bepore ukusuka kumphezulu ukuya ngaphakathi.

Le gradient ivumela ukuhluzwa okusebenzayo ngakumbi, njengoko amasuntswana amakhulu avalelwe

kumphezulu wangaphandle kwaye amasuntswana amancinci avaleleke kwindawo engaphakathi.

5. IiDiskhi zeMetal ezineNgxoxo ezininzi:

Ezi diski zenziwe ngokubeka iidiski ezininzi zobukhulu obahlukeneyo bepore kunye.

Oku kuvumela ukudalwa kweenkqubo zokucoca ezintsonkothileyo ezinokususa ububanzi

uluhlu lwezinto ezingcolisayo.

6. UkuWicking kweDiskhi zeMetal:

Ezi diski zenzelwe ukutsala ulwelo kwi pores.

Oku kubenza babe luncedo kwizicelo apho kubalulekile ukuba

kusasaza ulwelo ngokulinganayo, njengakwiiseli zamafutha kunye neebhetri.

7. IiDiscs zeMetal ezinePorous ze-Biomedical Applications:

Ezi diski zenziwe ngezinto ezihambelana ne-biocompatible, ezifana ne-titanium kunye nensimbi engenasici.

Zisetyenziswa kwiinkqubo ezahlukeneyo zonyango, ezifana nokufakelwa kwamathambo kunye neenkqubo zokuhanjiswa kweziyobisi.

3. Uhlalutyo lokuthelekisa kunye nesihluzo seDiskhi seMveli

1. Ukusebenza

Iidiski zetsimbi ezinamaqhekeza zibonelela ngenzuzo enkulu yokusebenza ngaphezulu kwezixhobo zemveli ngokwemiqathango yokuqina, ukusebenza kakuhle, kunye nokusebenza.

| Uphawu | IiDiscs zeMetal ezineNgxaki | Izinto zeMveli |

|---|---|---|

| Ukuqina | Phezulu | Phantsi |

| Ukusebenza kakuhle | Phezulu | Phakathi |

| Ukusebenza | Phezulu | Phakathi |

Iidiski zentsimbi ezinamazinyo zinokuqina ngokumangalisayo kwaye ziyakwazi ukumelana nemekobume erhabaxa, amaqondo obushushu aphezulu, kunye noxinzelelo olugqithisileyo. Oku kubenza balungele izicelo apho izinto zemveli ziya kuthotywa ngokukhawuleza okanye zisilele. Ukongeza, iidiski zetsimbi ezinamaqhekeza zibonelela ngobuchule obuphezulu malunga nokucoca, ukuhanjiswa kwamanzi, kunye nokusasazwa kwegesi. Isakhiwo sabo esiyinkimbinkimbi se-pore sivumela ulawulo oluchanekileyo phezu kwamazinga okuhamba kunye nokusabalalisa uxinzelelo, okukhokelela ekusebenzeni okuphuculweyo kwiintlobo ezininzi zezicelo.

2. Ukusebenza kweendleko

Nangona iidiski zetsimbi ezinobuncwane zinokuba neendleko eziphezulu zokuqala xa kuthelekiswa nezixhobo zemveli, indleko yazo yexesha elide ihlala iphezulu. Ukomelela kunye nokusebenziseka kwakhona kunciphisa imfuno yokutshintshwa rhoqo, kwaye iimfuno zabo zokugcinwa okuphantsi zinciphisa ngakumbi iindleko zokusebenza.

| Uphawu | IiDiscs zeMetal ezineNgxaki | Izinto zeMveli |

|---|---|---|

| Iindleko zokuqala | Phakathi | Phantsi |

| Iindleko zoLondolozo | Phantsi | Phakathi |

| Ukonga ixesha elide | Phezulu | Phakathi |

Ngokuhamba kwexesha, ukugcinwa kweendleko ezincitshisiweyo zokugcinwa kunye nokutshintshwa kunokugqithisa utyalo-mali oluphezulu lokuqala kwiidiski zetsimbi ze-porous. Oku kubenza babe isisombululo esineendleko zezicelo apho ukuthembeka kwexesha elide kunye nokusebenza kubaluleke kakhulu.

3.Impembelelo yokuSingqongileyo

Iidiski zetsimbi ezinamaqhekeza zibonelela ngeenzuzo ezininzi zokusingqongileyo ngaphezu kwezinto zemveli. Ukomelela kwazo kunye nokuphinda zisebenziseke kwakhona kunciphisa ukuveliswa kwenkunkuma, kwaye ukukwazi kwazo ukurisayikilishwa kwakhona kunciphisa indawo yazo yokusingqongileyo. Ukongezelela, iidiski zetsimbi ezinobuncwane zingasetyenziselwa ukudala iimveliso ezizinzileyo, ezifana neeseli zepetroli kunye neebhetri, ezifaka isandla kwikamva eliluhlaza.

| Uphawu | IiDiscs zeMetal ezineNgxaki | Izinto zeMveli |

|---|---|---|

| Uzinzo | Phezulu | Phantsi |

Iidiski zetsimbi ze-Porous ziyizinto eziphathekayo ezikhethiweyo ezinokuthi zincede ukunciphisa impembelelo yokusingqongileyo kunye nokukhuthaza uqoqosho olujikelezayo. Ukomelela kwazo, ukusebenziseka kwakhona, kunye nokusebenziseka kwakhona kuzenza zibe lukhetho olunoxanduva lokusingqongileyo kuluhlu olubanzi lwezicelo.

Ukuqukumbela, iidiski zetsimbi ezinobuncwane zinika indibaniselwano enyanzelisayo yokusebenza, ukusebenza kakuhle kweendleko, kunye nokuzinza kokusingqongileyo. Ukonga kwabo okugqwesileyo, ukusebenza kakuhle, kunye nokusebenza kubenza babe lolona khetho lufanelekileyo kwizicelo ezifunwayo, ngelixa ukonga kwabo ixesha elide kunye neenzuzo zokusingqongileyo kubenza babe lutyalo-mali oluzinzileyo. Njengoko ukuqhubela phambili kwetekhnoloji kunye nezicelo ezitsha zivela, iidiski zetsimbi ezinamanzi zikulungele ukudlala indima ebaluleke ngakumbi ekubumbeni ikamva lobunjineli kunye nemveliso.

4. UShishino-Izicelo ezizodwa kunye nothelekiso

I-Aerospace

Iidiski zetsimbi ezinamazinyo zidlala indima ebalulekileyo kwizicelo ze-aerospace, ngakumbi kwiinkqubo zokuhluza kunye nezixhobo ze-injini. Ukukwazi kwabo ukumelana namaqondo obushushu agqithisileyo, uxinzelelo, kunye nokungcangcazela kubenza bafaneleke kwezi ndawo zinzima.

Iinkqubo zoHlulo

Iidiski zetsimbi ezinamaqhekeza zisetyenziswa kwiinkqubo ezahlukeneyo zokuhluza kuyo yonke inqwelomoya, kubandakanya:

-

I-Fuel Filtration: Basusa ngokufanelekileyo ukungcola kumafutha eenqwelo-moya, ukuqinisekisa ukusebenza kakuhle kweenjini kunye nezinye iinkqubo ezibalulekileyo.

-

Ukuhluzwa kweHydraulic: Bahluza ulwelo olwenziwa ngamanzi, banqanda ukuguga kunye nokukrazula kwiinkqubo zehydraulic kunye nokuqinisekisa ulawulo oluchanekileyo lwamalungu enqwelomoya.

-

Ukuhluzwa koMoya: Bahluza umoya ongena kwi-cabin kunye neenkqubo ze-avionics, ukugcina indawo ecocekileyo nekhuselekileyo yabasebenzi kunye nabakhweli.

Amacandelo eNjini

Iidiski zetsimbi ezinamaqhekeza zikwasetyenziswa kumacandelo ahlukeneyo enjini, kubandakanywa:

-

I-Combustor Liners: Zibonelela ngomphezulu we-porous wokutshisa amafutha, ukuphucula ukusebenza kakuhle kunye nokunciphisa ukukhutshwa.

-

Izikhuselo Zobushushu: Zikhusela izinto ezibuthathaka kubushushu obugqithisileyo kunye nomothuko wobushushu.

-

Abahambisi abaHambayo: Baqinisekisa ukuhanjiswa okulinganayo kolwelo kunye neegesi, ukwenza ngcono ukusebenza kwe-injini.

Iimoto

Iidiski zetsimbi ezinamaqhekeza zifumana izicelo ezibanzi kushishino lweemoto, ngokukodwa kwiinkqubo zokukhupha kunye nokucoca.

Iinkqubo zokukhupha

-

Iziguquli zeCatalytic: Iidiski zetsimbi ezinamanzi zisebenza njengenxalenye yokuguqula i-catalytic, ukunciphisa ukukhutshwa okunobungozi kwigesi yokukhupha isithuthi. Babonelela ngomphezulu wendawo ephezulu ukwenzela ukusabela kwe-catalytic, ukuguqula ngokufanelekileyo ungcoliseko kwizinto ezinobungozi obuncinci.

-

I-Mufflers: Baphucula ukunciphisa ingxolo kwiimufflers, ukunciphisa isandi esiveliswa yinkqubo yokukhupha. Isakhiwo sazo esinemingxuma ngokufanelekileyo sitsala kwaye sichitha amaza omsindo.

Uhluzo

-

Ukuhluzwa komoya: Iidiski zetsimbi ezinamanzi zokucoca umoya ezingena enjini, zithintela ukungcoliseka kwamalungu anovakalelo kunye nokuqinisekisa ukusebenza kakuhle kwe-injini.

-

Ukuhluzwa kwe-oyile: Bahluza i-oyile ye-injini, basuse izinto ezingcolisayo kunye nokuqinisekisa ukuthambisa okufanelekileyo kwamalungu e-injini.

Ukwenziwa kweeKhemikhali

Iidiski zetsimbi ezinobuncwane zidlala indima ebalulekileyo ekuqhutyweni kweekhemikhali, ngokukodwa kwi-catalysis kunye neenkqubo zokwahlula.

Catalysis

-

IiNkxaso zeCatalyst: Iidiski zetsimbi ezinobuncwane zibonelela ngommandla ophezulu we-catalysts, okwenza kube lula ukuphendula kweekhemikhali. Bakhuthaza ukuhanjiswa okufanayo kwee-catalyst particles kunye nokuphucula ukuhanjiswa kobuninzi phakathi kwee-reactants kunye ne-catalysts.

-

I-Fixed-Bed Reactors: Zisebenza njengezinto zokupakisha kwii-reactors zebhedi esisigxina, ziququzelela uqhagamshelwano olulawulwayo phakathi kwee-reactants kunye ne-catalysts. Ubume babo obufanayo buqinisekisa ukuhamba kakuhle kunye nokusebenza kakuhle kokuphendula.

Iinkqubo zokwahlula

-

Ukuhluzwa: Iidiski zetsimbi ezinamaqhekeza zisetyenziselwa kwiinkqubo zokucoca ukususa ukungcola kwiimveliso ezahlukeneyo zeekhemikhali. Ubungakanani bepore obulawulwayo buvumela ukwahlulwa okukhethiweyo kwezinto eziqinileyo kulwelo.

-

Ukwahlula kweMembrane: Zisetyenziselwa kwiinkqubo zokuhlukana kwe-membrane, ezifana nokusabalalisa kwegesi kunye ne-pervaporation. Ulwakhiwo lwazo lwe-porous luvumela ukwahlula okukhethiweyo kweegesi okanye ulwelo olusekelwe kwiimpawu zabo ze-molecular.

Izixhobo zonyango

Iidiski zetsimbi ezinobuncwane ziye zafumana ukugqwesa kwizicelo zezixhobo zonyango, ngokukodwa kwiinkqubo zokufakelwa kunye nokucoca.

Ukufakelwa

-

Ukufakelwa Kwethambo: Iidiski zetsimbi ezinamaqhekeza zisetyenziselwa ukufakelwa kwamathambo, njengokufakelwa kwamathambo kunye nokufakelwa kwamazinyo. Isakhiwo sabo se-porous sikhuthaza i-ingrowth yamathambo kunye ne-osseointegration, ukuqinisekisa ukuzinza kwexesha elide kunye nokusebenza.

-

I-Tissue Engineering Scaffolds: Basebenza njenge-scaffolds yobunjineli bezicubu, ukubonelela ngesakhelo esixhasayo sokukhula kweeseli kunye nokuvuselelwa kwezicubu. Isakhiwo sabo se-porous sivumela ukungena kweeseli kunye nokusabalalisa izondlo, ukukhuthaza ukubunjwa kwezicubu.

Iinkqubo zoHlulo

-

I-Blood Filtration: Iidiski zetsimbi ezinama-porous zisetyenziswa kwiinkqubo zokuhluza igazi, ezifana nezihluzo ze-hemodialysis. Ubungakanani babo obulawulwayo bepore buvumela ukukhutshwa okukhethiweyo kokungcola kwigazi ngelixa kugcinwe iinxalenye ezibalulekileyo zegazi.

-

Iinkqubo zokuhanjiswa kweziyobisi: Zibandakanywe kwiinkqubo zokuhanjiswa kweziyobisi, ezinje ngeestents kunye nokufakelwa. Isakhiwo sabo se-porous sivumela ukukhululwa okulawulwayo kwamachiza, ukubonelela unyango lwendawo kwiimeko ezithile zonyango.

Iimpawu zeSintered Porous Metal Discs

| Uphawu | Ixabiso |

|---|---|

| Izinto eziphathekayo | Insimbi engenasici, ubhedu, i-nickel |

| Indlela Yokuvelisa | Sintering |

| Ubungakanani bePore | I-Micrometers ukuya kwi-millimeters |

| I-Porosity | 30% ukuya kwi-90% |

| Iingenelo | Ukuqina okuphezulu, ukusebenza kakuhle, kunye nokusebenza; Ukusebenziseka kwakhona; I-Biocompatibility (yezinto ezithile) |

| Iingxaki | Iindleko zokuqala eziphezulu xa kuthelekiswa nezinto zemveli |

Iidiski zetsimbi ze-Sintered zithande ukuthandwa kakhulu kwizicelo zemizi-mveliso ngenxa yeempawu zazo ezizodwa kunye neenzuzo. Zenziwe nge-sintering powder yensimbi kwiqondo lokushisa eliphezulu, elenza isakhiwo esine-porous kunye nobukhulu obufanayo kunye nokusabalalisa. Esi sakhiwo sibenza balungele usetyenziso olwahlukeneyo, kubandakanya:

* Ukuhluzwa: Iidiski zetsimbi ezinabileyo zisenokusetyenziswa ukucoca uluhlu olubanzi lolwelo, kuquka ulwelo, iigesi, kunye nodaka. Zisebenza ngokufanelekileyo ekususeni ukungcola kula ma-fluid, okwenza kube yinto efanelekileyo yokusetyenziswa kwiinkqubo zoshishino ezifuna amanqanaba aphezulu okucoceka.

* Ukusasazwa kolwelo: Iidiski zetsimbi ezinabileyo zisenokusetyenziswa ukusasaza ulwelo ngokulinganayo kumphezulu. Oku kubenza balungele izicelo ezifana neeseli zepetroli kunye neebhetri, apho kubalulekile ukusasaza ulwelo ngokulinganayo ukunyusa ukusebenza.

* Ukugqithiselwa kobushushu: Iidiski zetsimbi ezinabileyo zinokusetyenziswa ukuhambisa ubushushu ukusuka komnye umgangatho ukuya komnye. Zisebenza kakuhle ekuqhubeni ubushushu, nto leyo ezenza zilungele izicelo ezifana nokutshintsha ubushushu kunye neesinki zobushushu.

Ukongeza kwiipropathi zabo ezisebenzayo, iidiski zetsimbi ezifakwe kwi-sintered zikwabonelela ngeenzuzo ezininzi kwizinto zemveli, ezinje:

* Ukuqina okuphezulu: Iidiski zetsimbi ze-Sintered zomelele kakhulu kwaye zinokumelana nemekobume erhabaxa. Ziyakwazi ukumelana nomhlwa, ukhukuliseko, kunye nokuguga nokukrazuka.

* Ukusebenziseka kwakhona: Iidiski zetsimbi ze-Sintered porous zingaphinda zisetyenziswe ngamaxesha amaninzi, nto leyo eyenza ukuba ibe sisisombululo esingabizi kakhulu.

* Biocompatibility (kwimathiriyeli ethile): Ezinye iidiski zetsimbi ezisinyibilikisiweyo zenziwe ngezinto ezihambelana nebhayoloji, ezifana netitanium kunye nentsimbi engatyiwayo. Oku kubenza balungele ukusetyenziswa kwizifakelo zonyango kunye nezixhobo.

Ububi obukhulu kuphela beediski zetsimbi ze-sintered ziindleko zabo zokuqala xa kuthelekiswa nezinto zemveli. Nangona kunjalo, ukugcinwa kweendleko zabo zexesha elide, ngenxa yokusetyenziswa kwakhona kunye nokuqina kwazo, kunokunciphisa le ndleko yokuqala.

Ngokubanzi, iidiski zetsimbi ze-sintered ziyinto esebenzayo kwaye exabisekileyo enokusetyenziswa kuluhlu olubanzi lwezicelo zoshishino. Iipropathi zabo ezizodwa kunye neengenelo zibenza babe lolona khetho lufanelekileyo lwezicelo ezifuna ukuqina okuphezulu, ukusebenza kakuhle, kunye nokusebenza.

Izifundo zeCase kunye neMizekeliso yeHlabathi yokwenyani

Nazi ezinye zezifundo ezineenkcukacha ezibonisa ukusebenza kakuhle kweediski zetsimbi ze-porous kwizicelo ezithile, kunye nothelekiso kunye neemeko apho izinto zemveli zisetyenziswe kwiimeko ezifanayo:

I-Case Study 1: UkuHlungwa kweeSeli zeFuel

Ingxaki: Kwiiseli zepetroli, ukungcola kwi-gas stream kunokuvala i-electrodes kunye nokunciphisa ukusebenza kakuhle. Izihluzi zamaphepha esintu zihlala zisetyenziselwa ukususa ezi zingcolisi, kodwa zinokuvaleka ngokukhawuleza kwaye zifune ukutshintshwa rhoqo.

Isisombululo: Iidiski zetsimbi ezinamanzi zingasetyenziselwa ukuhluza umjelo werhasi kwiiseli zamafutha. I-porosity yabo ephezulu kunye nobukhulu be-pore obulawulwayo buvumela ukuba basuse ngokufanelekileyo ukungcola ngaphandle kokunciphisa kakhulu ukuhamba kwegesi. Ukongeza, iidiski zetsimbi ezinamanzi zomelele kakhulu kwaye zinokumelana nemekobume erhabaxa yeseli yamafutha.

Iziphumo: Ukusetyenziswa kweediski zetsimbi ezinobuncwane kwiiseli zepetroli kuye kwakhokelela ekuphuculeni okubonakalayo ekusebenzeni kunye nokunciphisa iindleko zokugcina. Kwisifundo esinye, ukusetyenziswa kweediski zetsimbi ezinobuncwane kwandisa ukusebenza kakuhle kweeseli ze-fuel nge-10% kunye nokunciphisa iindleko zokugcina ngama-50%.

Uthelekiso: Xa kuthelekiswa nezihluzo zamaphepha emveli, iidiski zentsimbi ezineentsimbi zibonelela ngeenzuzo ezininzi. Zihlala ixesha elide, zisebenza ngakumbi, kwaye zifuna ukutshintshwa rhoqo. Oku kubenza babe sisisombululo esineendleko eziphezulu zokuhluza iiseli zamafutha.

I-Case Study 2: I-Exhaust System Mufflers

Ingxaki: Iimufflers zesixokelelwano sokuphuma kwesiqhelo zihlala zisebenzisa i-fiberglass okanye uboya beceramic njengemathiriyeli efunxa isandi. Nangona kunjalo, ezi zixhobo zinokuhla ngokuhamba kwexesha kwaye zingasebenzi kakuhle. Ukongeza, banokuba yingozi yomlilo.

Isisombululo: Iidiski zetsimbi ezinamanzi zingasetyenziswa njengezinto ezifunxa isandi kwi-exhaust system mufflers. Isakhiwo sazo esinemingxuma ngokufanelekileyo sitsala kwaye sichitha amaza omsindo. Ukongeza, iidiski zetsimbi ezinamanzi ziqinile kwaye ziyakwazi ukumelana nobushushu obuphezulu kunye noxinzelelo lwenkqubo yokukhupha.

Iziphumo: Ukusetyenziswa kweediski zetsimbi ze-porous kwi-mufflers ye-exhaust system kuye kwakhokelela ekunciphiseni okukhulu kokukhutshwa kwengxolo. Kolunye uphononongo, ukusetyenziswa kweediski zetsimbi ezinabileyo kunciphise ukukhutshwa kwengxolo ukuya kuthi ga kwi-10 dB.

Uthelekiso: Xa kuthelekiswa nezinto zemveli ezifunxa isandi, iidiskhi zetsimbi ezinentunjana zibonelela ngeenzuzo ezininzi. Zihlala ixesha elide, zisebenza ngakumbi ekunciphiseni ukukhutshwa kwengxolo, kwaye zibeka ingozi encinci yomlilo. Oku kubenza babe sisisombululo esinqweneleka ngakumbi kwi-exhaust system mufflers.

I-Case Study 3: Ukuhluzwa kwegazi kwi-Hemodialysis

Ingxaki: Kwi-hemodialysis, igazi lidlula kwisihluzo ukuze kususwe ukungcola. Izihluzi zedialysis zemveli zihlala zisebenzisa iinwebu zeselulosi njengemathiriyeli yokucoca. Nangona kunjalo, i-cellulose membranes iyakwazi ukungcoliswa kwaye kunokuba nzima ukuyicoca.

Isisombululo: Iidiski zetsimbi ezinamaqhekeza zingasetyenziswa njengezinto zokucoca kwiifilitha ze-hemodialysis. Ubungakanani bepore babo obulawulwayo bubavumela ukuba bakhethe ukususa ukungcola egazini ngelixa begcina izinto ezibalulekileyo zegazi. Ukongeza, iidiski zetsimbi ezinamaqhekeza ziqinile kwaye zinokucocwa ngokulula.

Iziphumo: Ukusetyenziswa kwee-discs zetsimbi ze-porous kwi-hemodialysis filters kuye kwakhokelela ekuphuculeni okubonakalayo kumgangatho wonyango lwe-dialysis. Kwisifundo esinye, ukusetyenziswa kweediski zetsimbi ezinobuncwane kunciphisa amanqanaba okungcola egazini ukuya kuma-50%.

Uthelekiso: Xa kuthelekiswa neenwebu zeselulosi zemveli, iidiski zetsimbi ezinentunjana zibonelela ngeenzuzo ezininzi. Zihlala ixesha elide, zisebenza ngakumbi ekususeni ukungcola, kwaye ziyakwazi ukucocwa lula. Oku kubenza babe sisisombululo esinqweneleka ngakumbi kwizihluzi ze-hemodialysis.

Ezi zifundo zibonisa ukusebenza kakuhle kweediski zetsimbi ezinobuncwane kwiinkqubo ezahlukeneyo. Iimpawu zabo ezikhethekileyo kunye neenzuzo zenza ukuba zibe yimpahla ebalulekileyo kwiintlobo ezininzi zezicelo zoshishino kunye nezonyango.

Ndiyathemba ukuba olu lwazi luluncedo. Nceda undazise ukuba unayo nayiphi na eminye imibuzo.

Ukuphononongwa kweziphumo eziphambili kuHlalutyo lokuthelekisa

Uphononongo lwethu kwihlabathi leediski zetsimbi ezinamanzi luveze iimbono ezininzi eziphambili. Ngokuyintloko, iidiski zetsimbi ezinamaqhekeza zibonelela ngeenzuzo ezizodwa ngaphezu kwezixhobo zemveli kumashishini ahlukeneyo ngenxa yokuqina kwazo okuphezulu, ukusebenza kakuhle, kunye nokusebenza. Ngokubhekiselele ekusebenzeni, ezi diski zivelele kwiindawo ezinomngeni, zinika ubomi obude kunye nokuchasana okungcono kwiimeko ezinzima. Indleko-ngempumelelo yenye indawo apho i-porous metal discs ikhanya, inika ukugcinwa kwexesha elide nangona iindleko zokuqala zinokuthi ziphakame. Ngaphaya koko, impembelelo yazo yokusingqongileyo ayichaphazeli kangako, ihambelana kakuhle nemfuno ekhulayo yezenzo zemizi-mveliso ezizinzileyo.

Iingcamango zokuGqibela kwindima yeeDiscs zeMetal ezinePorous kwizicelo zoShishino

Iidiski zetsimbi ezinamaqhekeza azikho nje izinto; baguqula izinto kwizicelo zemizi-mveliso. Ukusuka kwi-aerospace ukuya kwizixhobo zonyango, ezi diski zibeka imigangatho emitsha yokusebenza kunye nokuthembeka. Ukuguquguquka kwabo kunye nokusebenza kakuhle kubenza balungele uluhlu olubanzi lwezicelo, kubonisa utshintsho olubalulekileyo kwindlela amashishini ajongana ngayo nokukhethwa kwezinto kunye noyilo. Njengoko itekhnoloji iqhubela phambili, sinokulindela ukudityaniswa okukhulu ngakumbi kweediski zesinyithi ezinamanzi kwizicelo ezitsha nezintsha, ziqinisa ngakumbi ukubaluleka kwazo kumhlaba woshishino.

Ngaba uneengcinga malunga nosetyenziso lwexesha elizayo lweediski zetsimbi ezinentunjana? Ngaba ukhe wadibana nemiceli mngeni ekhethekileyo okanye impumelelo ekuyisebenziseni kwishishini lakho?

Mhlawumbi unemibuzo malunga neepropati zabo, iindlela zokuvelisa, okanye iimeko ezithile zokusetyenziswa?

Ndiyakukhuthaza ukuba wabelane ngamabali akho, imibuzo kunye nokuqonda nathi.

Nceda ufikelele kwi-imeyileka@hengko.com.

Igalelo lakho alamkelekanga nje; kubalulekile ekwandiseni ingxoxo yethu kunye nokwenza nzulu ulwazi lwethu

malunga nala macandelo ahlukeneyo kunye abalulekileyo kushishino lwangoku.

Ixesha lokuposa: Nov-17-2023