-

ISintered Porous Metal Stainless Steel Bacteria HEPA Filter for Medical Oxygen Concentrator

I-HENGKO Sintered metal porous metal bacterial yentsimbi engenastainless i-HEPA filter for Medical Oxygen Concentrator yamkela ibakala lezonyango imathiriyeli yentsimbi, inentengiso...

Jonga iinkcukacha -

HENGKO® Grab Sampler Filter

Ukwazisa: I-Sampler Grab Sampler eneSintered Metal Filter, isixhobo esifanelekileyo sesampuli esichanekileyo nesithembekileyo kuluhlu olubanzi lwamashishini. Le nto entsha...

Jonga iinkcukacha -

I-Porous Metal 316L Isihluzi se-catalytic reactions ye-Granular Bed Filtration

Ukwazisa i-Porous Metal 316L Isihluzi-Isisombululo sakho sokumisa esinye sokuFumana imichiza! Ngaba udiniwe ukujongana neekhemikhali ezingasebenzi kakuhle nezintsonkothileyo...

Jonga iinkcukacha -

I-Monocrystalline silicon yoxinzelelo loxinzelelo lwe-sintered metal porous filter disc

Ukusebenzisa i-crystal silicon piezoresistive iteknoloji yoxinzelelo lwenzwa yoxinzelelo, inkqubo yenkqubo yokulinganisa inqanaba lolwelo usetyenziso lwe-sintered filter disc material:...

Jonga iinkcukacha -

ISintered Stainless Steel Interchangeable Sensor Housing yeSensor yoxinzelelo

I-sensor yendlu inokutshatyalaliswa ngokuguquguqukayo ukukhusela inzwa ngokwayo ngokufanelekileyo, kwaye i-sensor yezindlu inomsebenzi wokufunxa ukothuka kunye ne-buf ...

Jonga iinkcukacha -

I-Air Compressor & Blower Silencers -Ukunciphisa ingxolo yezixhobo

Iicompressor zomoya kunye nezivuthela zinokufumaneka kwiindawo ezininzi zokusebenza. Ngamanye amaxesha usenokungazi nokuba zikhona ukuba abantu basebenzisa izithulisi ezihluziweyo okanye umoya...

Jonga iinkcukacha -

Isihluzo sentsimbi esine-Sintered esithengisayo, i-Male Thread G1-1/2 okanye i-G2

3 5 iMicron Sintered Pneumatic Exhaust Muffler Silencer/Diffuse air & Noise Reducer. Iimuffler ze-pneumatic ezenziwe nge-HENGKO ezikumgangatho ophezulu wentsimbi engenasici zidibana...

Jonga iinkcukacha -

Izicoci zeGesi eziCoca ngokuPhezulu eziShiyiweyo zoHlulo lweSicelo esiSinye seMiyilelo yokuHambisa okuPhantsi

Izicoci zeGesi eziSintered Filtered for Sinye, Lowflow Rate Rate Applications Eyilelwe ucoceko oluphezulu kunye nezicelo zococeko eziphezulu ezifuna amanqanaba okungcola...

Jonga iinkcukacha -

I-OEM Fiber Collimator Diameter 7mm Fiber Porous Metal Stainless Steel Filter

Le mveliso ingasetyenziselwa ukudibanisa ifayibha okanye ukudibanisa ukugxila. Ukusetyenziswa kwe-collimation, nokuba yimowudi enye okanye i-multimode fiber ingasetyenziswa. Ukuba isetyenziswa...

Jonga iinkcukacha -

IGeometrical Essential Oyile yeNecklace Diffuser Porous Metal Aromatherapy Jewelry pendant

Ubucwebe be-Diffuser yindlela engaphezulu nje kwendlela elula yefashoni: ubucwebe be-diffuser busebenzisa i-aromatherapy, enomzimba ohlala ixesha elide, wengqondo kunye nowomoya ...

Jonga iinkcukacha -

I-Stainless Steel Exhauss-I-Porous Metal Filter Muffler

Isithulisi / Isihluzi esenziwe ngesinyithi esinezingxobo Izithulisi ezincinci / izihluzi ezenziwe ngesinyithi esinemingxuma kunye nezicelo ezininzi. Iyanciphisa ingxolo kwaye yenzelwe ukukhetha ...

Jonga iinkcukacha -

I-Porous Metal Muffler Filter Exhaust Pneumatic Solenoid Valve

UKHETHO LWEZOQOQOSHO KWISIQINISEKISO ESININGI SOKUHLUZA KUNYE NE-MUFFING Filter-Mufflers banokungena okukhethiweyo ngokucoca kunye nokusasazwa komoya ...

Jonga iinkcukacha -

I-HENGKO yentsimbi yokucoca icwecwe lokuvavanya idiskhi yovavanyo lwebhentshi yaseLabhoratri

Igqibelele: -Uvavanyo lwebhentshi yeLabhoratri yovavanyo -Izifundo ezinokwenzeka -Ubungakanani obuncinci, uhlobo lwe-batch-uhlobo lweenkqubo zoyilo lwe-HENGKO kunye nokuvelisa i-bench-top filter, ipo...

Jonga iinkcukacha -

I-UHP Esulungekileyo eQinisekisiweyo yoMoya eNgaxutywanga yiNtsimbi ePhezulu ngoxinzelelo oluPhezulu lweSihluzo seSampulu...

I-HENGKO ye-Gas Sampling Filter inokwahlula izinto eziqinileyo kwiigesi kwiintlobo ezahlukeneyo zezicelo. Usetyenziso lubandakanya ukuhluzwa kwenkqubo, izihluzi zesampulu, ukupolishwa...

Jonga iinkcukacha -

Inkqubo yeSampulu yeSihlalutyi seGesi -Isihluzo esiPhezulu se-Inline ye-UHP ecocekileyo

HENGKO Isihluzi segesi esinoxinzelelo oluphezulu lokhuseleko oluthembekileyo ngokuchasene nokungcola. Le marike yokucoca, ukwahlukana kunye nokucocwa ikwancedisa i-deve...

Jonga iinkcukacha -

I-Pre-Filter ye-Industrial Flue Gas Sampling Probe-Isihluzo soxinzelelo oluphezulu

Isihluzi sangaphambili sesampulu yerhasi ye-industrial flue iisampulu zesampulu yerhasi enothuli oluphezulu ukuthintela ukuvaleka kwendlela yerhasi ngexesha lokuthatha isampulu yetyhubhu...

Jonga iinkcukacha -

Ababambeli be-Flashback kwiisilinda enye isiko sintered metal porous steel stainless f...

Imveliso Chaza Ingqikelelo yoyilo yale mveliso kukuthintela abasebenzisi ekusebenziseni umlilo ngengozi ukuvavanya ukuba kukho i-hydrogen. Umbambeli womlilo u...

Jonga iinkcukacha -

Isihluzi seWholeliseli yeWire Mesh yentsimbi engatyiwayo 10 yeMicron Sintered Tube yeM...

Izihluzi zentsimbi engenastainless zilungele ukusetyenziswa kwiinkcukacha zobunjineli ezibango ezifuna ukuhluzwa kwiimeko ezimbi zokusingqongileyo, njengejet en...

Jonga iinkcukacha -

I-HENGKO yokucoca intsimbi yentsimbi ye-VOC yeejenereyitha zothuli lwe-aerosol

Imveliso Chaza ii-VOCs zivela ikakhulu ekutshisweni kwamafutha kunye nezothutho ngaphandle; ngaphakathi endlwini kwiimveliso ezitsha ezifana namalahle kunye negesi yendalo, umsi ophuma kwi-smo...

Jonga iinkcukacha -

Ubunjineli obuphezulu boBunjineli beSintered Porous Metal Flame Arrestor Assemblies

Izibambi zomlilo zizixhobo zokhuseleko ezivumela ukuhamba kweegesi ezinokutsha ngelixa zikhusela ukutshisa. I-HENGKO iyila amacandelo ukuhlangabezana nemeko ethile yokuhamba...

Jonga iinkcukacha

Iimpawu eziphambili zeSintered Metal Filter

Izihluzi zetsimbi zentsimbi zineempawu ezininzi eziphambili, eziquka:

1. Ukusebenza kakuhle kokucoca:

Isihluzi sesinyithi esine-Sintered sinobungakanani obuncinci bepore kunye nendawo enkulu yomhlaba, enokususa ngokufanelekileyo ubumdaka kwiigesi ezahlukeneyo kunye nolwelo.

2. Ukuhambelana okubanzi kweekhemikhali:

Ezi zihluzo zenziwe ngezinto ezinokuxhathisa iikhemikhali eziphezulu, ezizenza zilungele imidiya eninzi eyonakalisayo.

3. Ukumelana nobushushu obuphezulu:

Izihluzi zetsimbi ezisinki zinozinzo oluhle kakhulu lwe-thermal, ezivumela ukuba zisebenze ngokufanelekileyo kumaqondo obushushu aphezulu.

4. Ukuqina:

Ezi zihluzo zomelele, zinamandla omatshini aphezulu kunye nokuxhathisa ukukrazula, ukhukuliseko kunye neempembelelo.

5. Ukusebenziseka kwakhona:

Ngokungafaniyo nezihluzi ezilahlwayo, izihluzi zetsimbi ezifakwe emanzini zinokucocwa kwaye ziphinde zisetyenziswe ngamaxesha amaninzi, zizenze zibe sisisombululo esineendleko eziphezulu kwizicelo zokuhluza.

Ukusetyenziswa kwesihluzo esiKhethekileyo seSintered Metal

Ngokwenyani izihluzi eziKhethekileyo ezihlala zisetyenziswa kwiSicelo esiQhelekileyo, iSicelo esiSetyenzisiwe siya kusetyenziswa

Kwiqondo lobushushu obukhethekileyo kakhulu,Uxinzelelo oluphezulu, kakhuluiMveliso eKonakalisayo kunye

Iindawo zovavanyo. Kwakhona abanye bafuna iMilo yoYilo oluKhethekileyo, ngoko unokuQhagamshelana

I-HENGKO yokuSombulula iiMfuno zakho zesihluzi sesinyithi se-OEM.

1. Ukucoca ulwelo

2. Ulwelo

4. Ukusasazwa

6. Ukuhluzwa kwegesi

7. Ukutya kunye nesiselo

Izihluzi zetsimbi ezisinki zisebenza ngeendlela ezininzi kwaye zinokusetyenziswa kuluhlu olubanzi lwezicelo.

Eminye yemisebenzi eqhelekileyo yezihluzo zetsimbi zentsimbi zezi:

1. Ukuhluzwa kolwelo:

Izihluzi zetsimbi zetsimbi zisetyenziswa kakhulu ekuhluzeni ulwelo olunjengamanzi, imichiza, kunye nezinyibilikisi.

Ezi zihluzo ziyakwazi ukususa i-particle, ukungcola, kunye nezingcoliso kulwelo, okwenza

zilungele ukusetyenziswa kwimizi-mveliso yamayeza, ukutya neziselo, kunye nemichiza.

Zikwasetyenziswa kwizityalo zokucocwa kwamanzi amdaka ukususa ungcoliseko kunye nongcoliseko emanzini.

2. Ukuhluzwa kweeGesi:

Izihluzi zetsimbi ezisiyiweyo zikwasetyenziswa ekuhluzweni kweegesi ezinjengomoya, igesi yendalo, kunye nezinye iigesi zemizi-mveliso.

Ziyakwazi ukususa i-particle, i-oli, kunye nezinye izinto ezingcolileyo kwiigesi, ezizenza zilungele ukusetyenziswa

izicwangciso zoshishino kunye nezorhwebo ezifana nemibhobho yegesi kunye neenkqubo zomoya ezicinezelekileyo.

3. Iziguquli zeCatalytic:

Izihluzi zetsimbi zetsimbi zisetyenziswa kwiziguquli ze-catalytic ukususa ungcoliseko oluyingozi kwiigesi zokukhupha isithuthi.

Banokuthi babambe kwaye bahluze into ethile, ngelixa bevumela ukuphendulwa kweekhemikhali okwenzeka kwi-catalytic.

abaguquli ukuba baqhubeke. Oku kunceda ukunciphisa ukukhutshwa kwezithuthi kunye nokuphucula umgangatho womoya.

4. Ulwelo:

Izihluzi zetsimbi zetsimbi zisetyenziswa kwiinkqubo ze-fluidization, apho zisetyenziselwa ukusasaza irhasi okanye ulwelo kwibhedi.

amasuntswana aqinileyo. Ubume be-porous of sintered metal filters buvumela ukusasazwa ngokulinganayo kolwelo, oluyimfuneko

iinkqubo ezifanelekileyo zokwenziwa kwamanzi.

5. Ukuhluzwa kwe-oyile:

Izihluzi zetsimbi zentsimbi zisetyenziswa kwiinkqubo zokuhluza ioyile ukususa ukungcola, ungcoliseko, kunye nenxalenye.

izinto ezivela kwi-oyile ye-injini, i-oyile ye-hydraulic, kunye nezinye ii-oyile zemizi-mveliso. Ezi zihluzo ziyakwazi ukumelana namaqondo obushushu aphezulu

kunye noxinzelelo, olwenza lube lulungele ukusetyenziswa kwizicelo zamashishini.

6. Izixhobo zonyango:

Izihluzi zetsimbi ezifakwe kwi-Sintered zisetyenziswa kwizixhobo zonyango ezifana ne-nebulizers kunye neenkqubo zokuhanjiswa kweziyobisi. Ezi

izihluzi ziyakwazi ukuhluza iintsholongwane, iintsholongwane, kunye nezinye izinto ezingcolisa amayeza kunye neegesi zonyango.

inceda ukuqinisekisa ukhuseleko lwesigulane.

7. I-Aerospace kunye noKhuselo:

Izihluzi zetsimbi zetsimbi zisetyenziswa kwi-aerospace kunye namashishini okhuselo kwiinkqubo ezahlukeneyo,

kubandakanywa ukuhluzwa kwamafutha, ukuhluzwa kwe-hydraulic fluid, kunye nokucoca umoya kunye negesi. Ezi zihluzo kufuneka zihlangabezane nokusebenza okungqongqo kunye nokhuseleko

Imigangatho, eyenza izihluzi zetsimbi zentsimbi zibe lukhetho olufanelekileyo kula mashishini.

INkxaso yeZisombululo zeNjineli

Ukutyhubela iminyaka, i-HENGKO isombulule ukuhluzwa okuntsonkothileyo kunye neemfuno zolawulo lokuqukuqela kwindawo ebanzi

uluhlu lwamashishini kulo lonke ihlabathi.Ukusombulula ubunjineli obuntsonkothileyo obulungiselelwe isicelo sakho yinjongo yethu kwaye

Ikwayinjongo yethu eqhelekileyo ukugcina izixhobo zakho kunye neeprojekthi ziqhuba kakuhle kwaye ngokuzinzileyo njengoko bekucwangcisiwe

Kutheni singasebenzi kunye ukuze sigqibezele ezi projekthi kunye kwaye soyise ubunzima, siphuhlise

izihluzi ezikhethekileyo zeeprojekthi zakho ezizodwa namhlanje.

Wamkelekile ekwabelaneni ngeProjekthi yakho kunye nomsebenzi kunye ne-HENGKO, siya kubonelela ngeSihluzo esiKhethekileyo seMetal

Isisombululo seeProjekthi zakho.

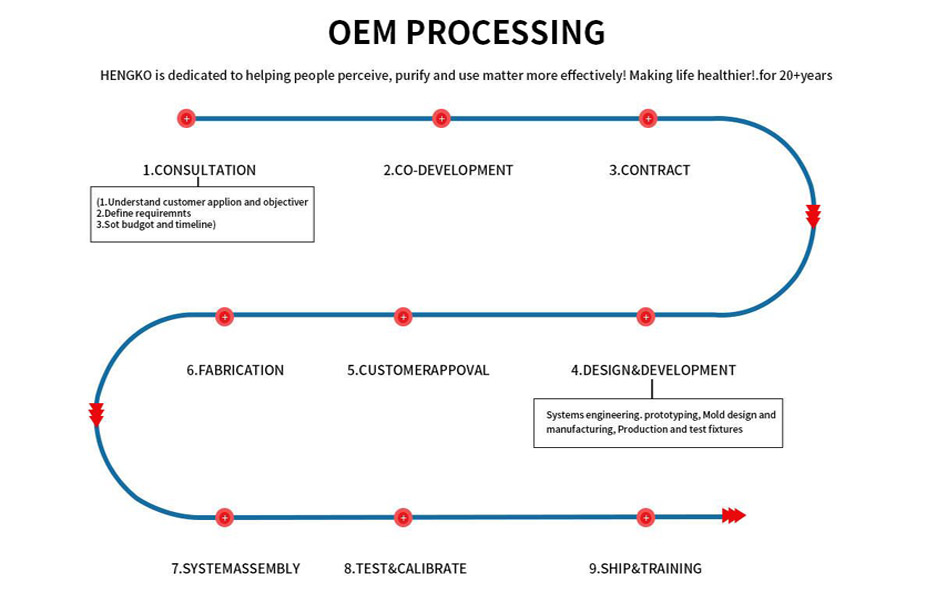

ISikhokelo seNyathelo ngeNyathelo sokuLungisa iSintered Metal Filter

Umzi-mveliso wakho woyilo lokucoca ukhethekileyo kwiiprojekthi zakho ezikhethekileyo eziphezulu, ukuba awukwazi ukufumana okufanayo okanye okufanayo

Iimveliso zokucoca, Wamkelekileukunxibelelana HENGKO ukusebenza kunye ukufumana esona sisombululo, kwaye nantsi inkqubo ye

Iifilitha ezikhethekileyo ze-OEM,Nceda Yijonge kwayeQhagamshelana nathithetha iinkcukacha ezingakumbi.

I-HENGKO izinikele ekuncedeni abantu baqonde, basulungekise kwaye basebenzise uMba ngokuFanelekileyo! Ukwenza ubomi bube nempilo ngaphezu kweminyaka engama-20.

1.Uthethwano kunye noQhagamshelwano HENGKO

2.Co-Development

3.Yenza iSivumelwano

4.Uyilo noPhuhliso

5.Ukwamkelwa kwabathengi

6. Ukwenziwa/Ukuveliswa kobuninzi

7. Systemassembly

8. Vavanya kwaye ulinganise

9. Ukuthumela ngenqanawa kunye noQeqesho

Usenemibuzo kwaye uthanda ukwazi iinkcukacha ezithe vetshe kwiIsihluzo esiKhethekileyo se-OEM, Nceda uzive ukhululekile ukuQhagamshelana nathi ngoku.

Kwakhona UnakoSithumele i-imeyileNgqo Ngokulandelayo:ka@hengko.com

Siza kuthumela umva ngeeyure ezingama-24, enkosi ngesigulana sakho!

FAQ malunga nezihluzo zeSintered Metal :

1. Yintoni isihluzo sesinyithi esine-sintered?

A: Aisihluzo sesinyithi esine-sinteredsisihluzo esenziwe ngokurhabula umgubo wentsimbi kunye ukwenza aimpahla enemingxuma

evumela ulwelo okanye iirhasi ukuba zidlule ngelixa ubambe amasuntswana okanye ukungcola.

2. Ziziphi iingenelo zokusebenzisa izihluzo zetsimbi ezine-sintered?

Izihluzi zetsimbi ze-Sintered zibonelela ngendibaniselwano eyodwa yeepropathi ezenza zibe luncedo kwizicelo ezahlukeneyo. Nazi ezinye zezibonelelo eziphambili:

1. Ukomelela kunye nokuqina:

Ngokungafaniyo nephepha okanye izihluzi zelaphu, izihluzo zetsimbi ezisiyiweyo zomelele ngokumangalisayo kwaye zinokumelana noxinzelelo oluphezulu kunye namaqondo obushushu. Oku kubenza balungele izicelo zemizi-mveliso ezifana nokusetyenzwa kweekhemikhali, ukucokisa i-petrochemical, kunye nokuveliswa kwamandla.

2. I-porosity ephezulu kunye nokuhluzwa okuchanekileyo:

I-porosity elawulwayo yeefilitha zetsimbi edibeneyo ivumela ukuhluzwa okuchanekileyo kwamaqhekeza ukuya kubukhulu obuncinci kakhulu. Oku kuphunyezwa ngokulawula ngononophelo ubungakanani kunye nokuhanjiswa kweepores ngexesha lenkqubo ye-sintering.

3. Ukumelana nokuMhlwa:

Izihluzi ezininzi zetsimbi ezenziwe ngentsimbi ecocekileyo okanye ezinye iintsimbi ezikwazi ukumelana nomhlwa, zizenza zilungele ukusetyenziswa ngemichiza erhabaxa kunye nolwelo. Oku kunciphisa imfuno yokutshintshwa rhoqo kunye nokugcinwa.

4. Ukucoceka kunye nokusebenziseka kwakhona:

Ngokungafaniyo nezihluzi ezilahlwayo, izihluzi zetsimbi ezifakwe emanzini zinokucocwa ngokulula kwaye ziphinde zisetyenziswe, nto leyo ezenza zibe lukhetho olungabizi kakhulu kwaye lunobuhlobo nokusingqongileyo ekuhambeni kwexesha.

5. Ukumelana nokothuka kwe-thermal:

Izihluzi zetsimbi zetsimbi zinokumelana notshintsho olukhawulezayo kwiqondo lobushushu ngaphandle kokuqhekeka okanye ukugoba, zizenze zilungele ukusetyenziswa kwindawo ezinobushushu obuphezulu njengeeinjini zomoya kunye neenjini.

6. Ukuguquguquka:

Izihluzi zetsimbi zetsimbi zinokwenziwa ngokwezifiso ukuze zihlangabezane noluhlu olubanzi lweemfuno ngokobungakanani bepore, imilo, kunye nezinto eziphathekayo. Oku kubenza baqhelane nezicelo ezahlukeneyo kumashishini ahlukeneyo.

Nazi ezinye izibonelelo ezongezelelweyo ezifanele ukukhankanywa:

* Ulwakhiwo oludityanisiweyo:

Izihluzi zetsimbi ezisinki zinesakhiwo esingenamthungo, zisusa umngcipheko wokuvuza okuhambelana nezihluzo ezincamathisiweyo okanye ezithungelweyo.

* Ubomi benkonzo ende:

Ngenxa yokuqina kunye nococeko lwazo, izihluzi zetsimbi zentsimbi zinobomi obude kakhulu xa kuthelekiswa nezinye iintlobo zezihluzi.

* Ukuhambelana kwezinto eziphilayo:

Ezinye iintsimbi ezitshisiweyo ezifana ne-titanium ziyahambelana ne-biocompatible, zizenza zilungele ukusetyenziswa kwezonyango kunye namayeza.

Ngokubanzi, izibonelelo zokusebenzisa izihluzi zetsimbi ezifakwe emanzini zizenza ukuba zibe lukhetho olunyanzelisayo lwezicelo ezifunwayo apho ukusebenza okuphezulu, ukuqina, kunye nokusebenziseka kwakhona kubalulekile.

3. Zeziphi ezinye izicelo eziqhelekileyo zezihluzo zetsimbi zentsimbi?

A: Izihluzi zetsimbi zetsimbi zisetyenziswa kumashishini ahlukeneyo kubandakanya ukutya kunye nesiselo,

amayeza, iikhemikhali, i-petrochemical, unyango lwamanzi kunye neemoto.

Ngokuqhelekileyo zisetyenziselwa ukucoca ulwelo okanye iigesi ezifana ne-oyile, amafutha, igesi okanye amanzi.

4. Yintoni ekufuneka ihlawulwe ingqalelo xa ukhetha umenzi sintered isihluzo metal?

IMPENDULO: Xa ukhetha umenzi wokucoca isinyithi, khangela inkampani enamava kunye nobuchule kuyo

ukuvelisa izihluzi ezikumgangatho ophezulu, usebenzisa iinkqubo zokuvelisa eziphucukileyo kunye nobuchwepheshe, unikezela ngokwezifiso

iinketho kunye nenkxaso yobugcisa, kwaye inegama lenkonzo yabathengi kunye nokuhanjiswa Inkampani enegama elihle.

5. Zenziwa njani izihluzi zetsimbi ezisinyisiweyo?

Izihluzi zetsimbi zetsimbi zenziwe ngenkqubo enomdla ebandakanya ukuguqula umgubo wesinyithi ube yinto eyomeleleyo, enemingxuma. Nalu ucazululo lwenyathelo ngalinye:

1. Ukulungiswa komgubo wesinyithi:

Uhambo luqala ngomgubo wentsimbi, oqhele ukwenziwa ngentsimbi engatyiwa, ubhedu, i-nickel, okanye i-titanium. Ezi powders zinokufunyanwa ngeendlela ezahlukeneyo ezifana nokusila, i-atomization, okanye ukubola kweekhemikhali.

2. Ukuxuba kunye nokubumba:

I-powder yensimbi ixutywe kunye nezibophelelo kunye ne-lubricant ukuphucula ukuhamba kwayo kunye neempawu zokucinezela. Lo mxube ucinezelwe kwimilo efunekayo yecebo lokucoca usebenzisa uxinzelelo oluphezulu luyafa. Iimilo zinokuba ziidiski ezilula, iityhubhu ezintsonkothileyo, okanye iijiyometri ezintsonkothileyo ngokuxhomekeke kwisicelo.

3. Sintering:

Le yintliziyo yenkqubo apho kwenzeka khona umlingo. Imilo ecinezelweyo ifudunyezwa kwindawo elawulwayo kwiqondo lokushisa elingaphantsi kwendawo yokunyibilika kwesinyithi. Obu bushushu bubangela ukuba amasuntswana esinyithi adibane kunye kwiindawo zawo zoqhagamshelwano, enze uthungelwano olomeleleyo, oludityanisiweyo oluqhagamshelweyo ngelixa lusashiya isithuba esaneleyo esingenanto se porosity yesihluzi.

4. Ukugqiba nokucoca:

Nje ukuba sintered, into yokucoca iphinda iqhubekeke eyongezelelweyo njengokupholisa, de-binding (ukususwa kweearhente ezibophelelayo), kunye nokugqitywa komphezulu. Ezinye izihluzi zinokufuna ukwenziwa ngoomatshini okanye ukudityaniswa ukuze kuphunyezwe uhlobo olufunekayo lokugqibela.

5. Ulawulo lomgangatho kunye novavanyo:

Inqanaba lokugqibela libandakanya uqwalaselo olungqongqo lolawulo lomgangatho ukuqinisekisa ukuba isihluzi sihlangabezana nemigaqo efunekayo ye-porosity, ukuhanjiswa kobungakanani bepore, amandla, kunye nezinye iiparamitha. Oku kuhlala kubandakanya ukuhlolwa okubonakalayo, imilinganiselo yobukhulu, kunye novavanyo lokusebenza ngolwelo.

Kwaye voila! Umgubo wesinyithi othobekileyo uguqulwa ube yinto eyomeleleyo, enokuphinda isetyenziswe kwisihluzi esilungele ukujongana nemisebenzi eyahlukeneyo yokuhluza kuwo wonke amashishini.

Kubalulekile ukuba uqaphele ukuba kukho ukuhluka kwinkqubo echanekileyo ngokuxhomekeke kuhlobo lwetsimbi, iipropati ezifunwayo, kunye nomenzi othile. Obunye ubuchule bubandakanya ukusebenzisa iintsinga zentsimbi ezenziwe kwangaphambili endaweni yomgubo, okanye ukusebenzisa iindlela ezahlukeneyo zokufudumeza ezifana ne-microwave sintering.

Ngamafutshane, inkqubo ye-sintering idala ulwakhiwo lwentsimbi elomeleleyo kodwa olunerhashalala oluhluza ngokufanelekileyo ulwelo ngelixa ligcina izinto ezinqwenelekayo ezifana nobushushu obuphezulu kunye nokumelana noxinzelelo. Oku kwenza ukuba izihluzi zetsimbi ezine-sintered zibe sisixhobo esixabisekileyo kwiinkalo ezahlukeneyo, ukusuka kwizixhobo zonyango ukuya kubunjineli beemoto.

6. Zeziphi izinto eziqhelekileyo ezisetyenziselwa ukwenza izihluzo zetsimbi ezine-sintered?

A: Izihluzi zetsimbi zetsimbi zingenziwa kwizinto ezahlukeneyo ezibandakanya intsimbi engatyiwa, ubhedu, nickel, titanium.

kunye nezinye i-alloys. Ukukhethwa kwezinto kuxhomekeke kwisicelo esithile kunye neempawu ezifunwayo zesihluzi.

7. Ngaba isihluzo sesinyithi esine-sintered sinokwenziwa ngokwezifiso?

A: Ewe, izihluzi zetsimbi zetsimbi zingenziwa ngokwezifiso ukuhlangabezana neemfuno ezithile zezicelo ezahlukeneyo. Abavelisi

inokulungelelanisa ubungakanani bepore, ubukhulu, imilo kunye nezinye iiparameters ukwenza ngcono ukusebenza kokucoca.

8. Ndizicoca kwaye ndizigcine njani izihluzo zetsimbi ezisinkiweyo?

A: Izihluzi zetsimbi zetsimbi zinokucocwa ngokuhlanjwa ngasemva ngamanzi okanye ngomoya ocinezelweyo okanye ngokuntywiliselwa emanzini.

isisombululo sokucoca. Kubalulekile ukulandela iingcebiso zokucoca kunye nokugcinwa komenzi ukuze

qinisekisa ukusebenza kakuhle kwesihluzi kunye nobomi benkonzo.