Porous Metal Intsingiselo

Yintoni i-Porous Metal

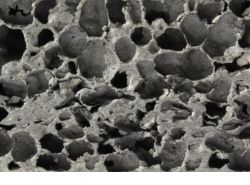

Kufuphi, Isinyithi esinamathambo zizinto ezinothungelwano oludityanisiweyo oluthathu lwe-pores, okanye i-voids, kwi-microstructure yazo evumela ulwelo okanye iigesi ukuba zihambe kwizinto eziphathekayo.

Ezi pores zihluka ngobukhulu ukusuka kwi-nanometers ukuya kwi-millimeters kwaye ngokuqhelekileyo zenziwe ngeenkqubo ezifana ne-sintering, i-foaming okanye i-electroplating. Iintsimbi ezinamaqhekeza zineempawu ezizodwa ezenza zibe luncedo kwiinkqubo ezahlukeneyo, kubandakanywa ukuhluzwa, i-catalysis, ukugcinwa kwamandla, kunye nobunjineli be-biomedical.

I-porosity yezi zinyithi inokulawulwa kwaye ilungiselelwe ukuhlangabezana neemfuno ezithile, ezifanaubungakanani pore, umthamo we pore, kwayeindawo ephezulu. Le tunability ivumela ukuthungwa kwesinyithi esinemingxuma ukukhawulelana neemfuno zezicelo ezahlukeneyo. Ngapha koko, i-pore edityanisiweyo yesakhiwo sesinyithi esine-porous ivumela ukufikeleleka okuphezulu kunye nokuhla koxinzelelo oluphantsi, oluququzelela ukuhamba kwamanzi kunye neenkqubo zokudlulisa ubunzima.

Namhlanje,Iintsimbi ezinamabhodlozidla ngokwenziwa ngeentsimbi zobunjineli eziqhelekileyo ezifana ne-aluminiyam, i-titanium, i-nickel kunye nobhedu, kodwa zisenokwenziwa ngezinto ezingaqhelekanga ezifana ne-magnesium okanye i-zinc. Iipropathi zetsimbi ezinobuncwane zixhomekeke kuhlobo lwetsimbi esetyenzisiweyo, inkqubo yokuvelisa, kunye nobukhulu kunye nokusabalalisa kwee-pores. Iintsimbi ezinamazinyo zingenziwa ngeendlela ezahlukeneyo ezifana namaphepha, iityhubhu, amagwebu kunye nomgubo, nto leyo ezenza izinto eziguquguqukayo kwizicelo ezahlukeneyo.

Njengoko ilandelayo idumileuluhlu lweentsimbi ezinamaqhekezaumzobo wesakhiwo kwimarike, ngethemba lokuba uya kukwenza wazi ngokucacileyo kwisinyithi esinemingxuma.

Isisombululo se-Corrosion-Resistant kwi-Advanced Filtration kunye ne-Gas Diffusion Application

I-Aluminiyam yePorous

UKhaphukhaphu kwaye uguquguqukayo woThutho oluPhuculweyo loBushushu kunye nokuNcitshiswa kwe-Acoustic

Porous Nickel

Amandla aphezulu, ukuchasana nobushushu obuphezulu, okufanelekileyo kwi-Advanced Catalysis kunye nezicelo zebhetri.

Isisombululo esineNdleko sokuCwangcisa ukuCwangcisa kunye nokuLawulwa kwePorosity kwiiBearings kunye neeFilters.

Iimpawu eziphambili kunye ne-Advanteji

I-Porosity:

Njengoko igama libonisa, isinyithi esine-porous sibonakaliswe kuthungelwano lwee-pores ezidibeneyo. I-Porosity inokwahluka ngokuxhomekeke kwinkqubo yokuvelisa kwaye isuka kwiipesenti ezimbalwa ukuya kwi-90%.

Indawo engaphezulu:

Iintsimbi ezinobuqhophololo zinomlinganiselo ophezulu womhlaba ukuya kumthamo wevolumu ngenxa yesakhiwo sazo esine-porous. Lo mmandla wandayo ungasetyenziselwa izicelo ezifana ne-catalysis, filtration kunye nokugcinwa kwamandla.

Iimpawu zoomatshini:

Iintsimbi ze-Porous zibonisa uluhlu lweempawu zomatshini, kuxhomekeke kwizinto eziphathekayo kunye ne-porosity. Iimpawu zomatshini zesinyithi zinokulungelelaniswa ngokulungisa ubungakanani bepore, imilo kunye nokusabalalisa.

Biocompatibility:

Ezinye iintsimbi ezinamanzi, ezifana ne-titanium kunye ne-alloys zayo, ziyahambelana ne-biocompatible kwaye zinokusetyenziswa kwizicelo ze-biomedical ezifana nokufakelwa.

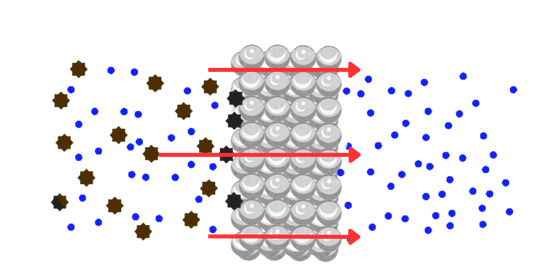

Ukuhamba kolwelo:

Iipore ezidityanisiweyo kwiintsimbi ezinamaqhekeza zivumela ukuhamba kwamanzi, okwenza kube luncedo kwizicelo ezifana nokuhluzwa kunye nokwahlula.

I-Thermal kunye ne-conductivity yombane:

I-thermal kunye ne-electrical conductivity ye-metal porous inokulungiswa ngokuguqula i-porosity kunye nentsimbi esetyenziswe kwinkqubo yokwenziwa.

Izihluzi eziSebenza ngokuPhezulu ezinoBubungakanani bePore obuLawulwayo kunye neeReyithi zokuHamba eziLungileyo zeGesi kunye nezicelo zolwelo.

Amacandelo ahlala ehleli kwaye angaGxiki kwii-Bearings kunye ne-Hydraulic Systems ezineePropati zokuthambisa ezongezelelweyo.

Izisombululo ezilungelelanisiweyo zokuThuthukiswa koBubushushu kunye nokuThuthukiswa koMninzi kwiiNkqubo zeMichiza kunye nePetrochemical kunye neMfezeko yoLwakhiwo oluPhezulu.

Esona sisombululo silungileyo soYilo kunye nobuNjineli bobuNjineli obuPhezulu bufuna iNgxaki yokuHlunga

Ngaphezulu kokuqonda kwangaphambili, Siyazi i-Sintered metal porous inokubonelela ngeendlela ezahlukeneyoukuhamba ngokwezifiso kunye neempawu zokucoca. Kwaye Le nto ikhethekileyo iveliswa nge-sintering, ebandakanya ukufudumeza umgubo wesinyithi kwiqondo lokushisa elingaphantsi kwendawo yokunyibilika kwayo, ukuvumela amaqhekeza ukuba adibanise ngelixa egcina i-porosity efunwayo. Unokuyibumba ngokulula, uyimatshini, kwaye uyilawule i-porosity yayo, uyenze ibe yimathiriyeli eguquguqukayo yokuphuhlisa naliphi na inani leemveliso ezizodwa okanye izisombululo zenkqubo ezibandakanya ukulawula nokulawula ulwelo kunye neegesi.

Masithi ujonge ezinye izixhobo ezikhethekileyo zeNkqubo yakho yokuHlunga. Xa kunjalo, Siyakumema ukubaQhagamshelana nathinamhlanje ukuphonononga ukuba izisombululo zethu zemithombo yeendaba zentsimbi zinokunceda njani ekusombululeni imingeni yakho yobunjineli boyilo. Masisebenzisane kwaye sichonge izisombululo ezilungiselelweyo ezihlangabezana neemfuno zakho ezizodwa.

Isicelo esiQhelekileyo seNsimbi yeNsimbi

Izihluzi zetsimbi kunye ne-porous metal zisetyenziswa kuluhlu olubanzi lwezicelo ngenxa yeempawu zazo ezikhethekileyo.

kubandakanywa nokungena okuphezulu, i-porosity elawulwayo, kunye namandla omatshini. Ngezantsi kukho izicelo eziqhelekileyo:

1. UHlelo kunye noKwahlula:

Izihluzi zesinyithi ezinamazinyo zisetyenziswa kakhulu kwiinkqubo zokuhluza kwimizi-mveliso, apho zinceda ukwahlula izinto eziqinileyo kulwelo okanye kwiigesi.

Ziluncedo kakhulu kumashishini afana ne-petrochemical, ukusetyenzwa kweekhemikhali, kunye ne-oyile kunye negesi ngenxa yokuchasana nobushushu obuphezulu kunye nezinto ezinobungozi.

2. Ukukhula kunye nokusabalalisa:

Xa irhabula, isinyithi esinentunja sisetyenziselwa ukusasaza igesi kulwelo, ngokufuthi ukuphefumla ulwelo.

Oku kusetyenziswa ngokuqhelekileyo kunyango lwamanzi amdaka, imveliso yamayeza, kunye neenkqubo zokutya neziselo.

3. Ulawulo loxinzelelo:

Amalungu esinyithi anombhobho anokusetyenziswa kwizixhobo zokulawula uxinzelelo ezifana neevalvu zokunciphisa uxinzelelo okanye ukuphefumla kumashishini ahlukeneyo kubandakanya iimoto, i-aerospace, kunye noomatshini bemizi-mveliso.

4. Izivamvo:

Iintsimbi ezinamaqhekezana zingasetyenziswa kwiintlobo ezithile zezivamvo ngenxa yokukwazi kwazo ukuvumela iigesi kunye nolwelo ukuba zidlule.

Ezi zinokufunyanwa ekujongweni kokusingqongileyo, ekusetyenzweni kwamashishini, kunye nezicelo zokhathalelo lwempilo.

5. Ukudambisa isandi:

Iintsimbi ezinamabhodlo zihlala zisetyenziselwa ukudambisa isandi okanye ukunciphisa ingxolo kumashishini ahlukeneyo, ukusuka kwiinkqubo zokukhupha iimoto ukuya koomatshini boshishino.

6. IziTshintshisi zoBubushushu:

Iintsimbi ezinamaqhekeza zibonelela nge-thermal conductivity elungileyo kunye neempawu zokutshintsha ubushushu, zizenza zibalaseleyo kwizicelo zokutshintsha ubushushu, ngakumbi kumashishini asebenza ngamaqondo obushushu aphezulu.

7. Iinkxaso zeCatalyst:

Kwiinkqubo zeekhemikhali, isinyithi esine-porous singasetyenziselwa njengenkxaso ye-catalyst, evumela ukuba indawo enkulu yendawo yokusabela yenzeke. Oku kubonakala ngokuqhelekileyo kwishishini lepetrochemical.

8. Ii-Electrodes zebhetri:

Iintsimbi ezinamabhobhothi zingasetyenziselwa ukuveliswa kwee-electrode zebhetri. I-porosity ivumela indawo engaphezulu, ukuphucula ukusebenza kwebhetri.

9. Usetyenziso lweBiomedical:

Izinyithi ezinamazinyo, ngakumbi i-titanium enemingxuma kunye nengxubevange yayo, ifumene usetyenziso olubanzi kwindawo yebhayomedical, njengokufakwa kwamathambo kunye nokufakelwa kwamazinyo. Ubume babo obunobuqhetseba bukhuthaza ukungena kwamathambo, okukhokelela ekudityaneni ngcono nomzimba.

10. IiSeli zeFuel:

Amalungu esinyithi anembobo zinokusebenza njengee-electrode kwiiseli zamafutha, ezivumela iigesi ukuba zihambe ngokulula ngelixa uqhuba umbane.

Nceda uqaphele ukuba iinkcukacha zokusetyenziswa kwesinyithi okanye izihlungi zixhomekeke kuhlobo lwentsimbi edibeneyo okanye i-alloy kunye nohlobo oluchanekileyo lwe-porosity (ubungakanani, ukusabalalisa, kunye nokudibanisa kwee-pores).

ke ukuba unayo nayiphi na imibuzo malunga nesicelo se-porous sintered metal filter, nceda uzive ukhululekileuqhagamshelane HENGKOnge-imeyileka@hengko.com.

FAQ Malunga Metal Metal

1. Kutheni usebenzisa isinyithi esinemingxuma ukwenza isihluzo?

Isinyithi se-porous sisixhobo esinesakhiwo esikhethekileyo esiqulethe ii-pores ezidibeneyo okanye i-voids ngaphakathi kwesakhelo esiqinileyo. Ubungakanani be-pore kunye nokusabalalisa kunokuthi kulungiselelwe ukuhlangabezana neemfuno ezithile zesicelo, okwenza kube yinto eguquguqukayo yoluhlu lwamashishini.

Ke njengaloo msebenzi ukhethekileyo, iintsimbi ezinePorous zidla ngokusetyenziswa ekwenzeni izihluzi ngenxa yezizathu ezininzi:

1. Ubungakanani bePore obulawulwayo:Iintsimbi ezinembobo zingenziwa ngobunjineli ukuze zibe nobukhulu obuchanekileyo bepore. Oku kuvumela ukudalwa kwezihluzi ezinamandla athile okucoca, njengokususa amasuntswana obungakanani obuthile.

2. Amandla aphezulu:Izihluzi zetsimbi zinamandla amakhulu omatshini, nto leyo eyenza ukuba yomelele kwaye yomelele. Banokumelana noxinzelelo oluphezulu kunye neemeko zobushushu ezinokonakalisa ezinye iintlobo zezihluzi.

3. Ukumelana neMichiza:Iintsimbi zihlala zimelana neentlobo ngeentlobo zeekhemikhali, zizenza zilungele ukusetyenziswa kwindawo apho zinokuchanabeka kwizinto ezidlekayo.

4. Ukusebenziseka kwakhona:Izihluzi zetsimbi zinokucocwa kwaye ziphinde zisetyenziswe, nto leyo enexabiso eliphantsi kwaye ihambelana nokusingqongileyo.

5. Uzinzo lweThermal:Izihluzi zentsimbi zinokugcina ubushushu obuphezulu, obunokuthi kungabikho njalo kwizihluzi ezenziwe ngemathiriyeli yepolymer.

6. Ukufikeleleka:Ngenxa yobume bazo, ezi zixhobo zivumela iqondo eliphezulu lokuhamba kwamanzi ngelixa zibamba ngokufanelekileyo kwaye zigcina amasuntswana.

7. Ukukwazi ukuhlamba umqolo:Izihluzi zetsimbi zinokuthi zihlanjwe ngasemva ukuze zisuse amaqhekeza abanjwe, okuvumela ukubuyiswa kwezinto ezixabisekileyo kunye nokwandisa ixesha lokuphila kwesihluzo.

Yiyo loo nto, kuxhomekeke kwisicelo kunye nohlobo lolwelo olufuna ukuhluzwa, izihluzi zentsimbi ezinabileyo zinokuba lolona khetho lubalaseleyo.

2. Yenziwa njani isinyithi esinemingxuma?

Isinyithi esinamanzi siqhele ukuveliswa ngenkqubo ebizwa ngokuba yi-sintering, ebandakanya ukufudumeza umgubo wesinyithi kwiqondo lobushushu elingaphantsi nje kwendawo yokunyibilika, evumela amasuntswana ukuba adibane kunye ngelixa egcina i-porosity efunwayo.

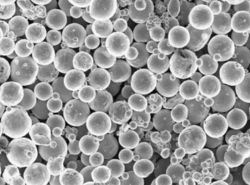

Inkqubo yokwenza isinyithi esine-porous ibandakanya ukudala i-voids okanye i-pores ngaphakathi kwesinyithi. Kukho iindlela ezininzi ezisetyenziswayo ukuphumeza oku, kubandakanya umgubo wesinyithi, i-sintering, kunye nokuveliswa okongeziweyo. Apha ngezantsi kukho inkcazo eyenziwe lula yendlela eqhelekileyo, i-powder metallurgy:

1. Ukuveliswa komgubo wesinyithi:Isinyathelo sokuqala ekudaleni isinyithi esine-porous kukuvelisa umgubo wesinyithi. Oku kunokwenziwa ngeendlela ezininzi, kuquka i-atomization (ukutshiza umlambo wesinyithi esinyibilikisiweyo kwigumbi apho siqina sibe ngumgubo) okanye ukugaya ngomatshini.

2. Ukudibanisa kunye nokuQinisa:I-powder yensimbi ixutywe kunye ne-agent ebophelelayo okanye izinto zokubamba indawo ukuze uncede ukugcina isakhiwo ngexesha lokucubungula. Umxube ke udityaniswe phantsi koxinzelelo oluphezulu kwi-die ukwenza i-compact "green". Ubume bokufa buzakumisela ubume bokugqibela benxalenye yentsimbi enombhobho.

3. Sintering:I-compact eluhlaza ke ifudunyezwa kwisithando somlilo kwiqondo lokushisa elingaphantsi kwendawo yokunyibilika kwesinyithi. Le nkqubo, eyaziwa ngokuba yi-sintering, ibangela ukuba amasuntswana esinyithi adibane. Ubushushu obuphezulu bubangela ukuba isibophelelo sendawo sitshiswe okanye sibe ngumphunga, sishiye ngasemva imingxuma.

4. Ukupholisa nokuQeda:Emva kwe-sintering, inxalenye yentsimbi ivumelekile ukuba iphole, emva koko inokuthi iqhube iinkqubo ezongezelelweyo ezifana nokugqiba okanye ukugubungela ukuphucula iimpawu zayo zomphezulu.

Enye indlela kukusebenzisa imveliso eyongeziweyo (eyaziwa ngokuba yi-3D printing), apho umgubo wesinyithi ukhethwa ngokukhethiweyo umaleko ngokomaleko osekelwe kwimodeli yedijithali. Oku kunokudala iimilo ezintsonkothileyo kunye nezakhiwo zepore zangaphakathi eziya kuba nzima okanye akunakwenzeka ukufikelela ngeendlela zemveli.

Ubungakanani be-pore, ukusabalalisa, kunye nokudibanisa kunokulawulwa kwinqanaba elikhulu ngexesha lokwenziwa kwenkqubo yokuvelisa, eyenza isinyithi se-porous silungele uluhlu olubanzi lwezicelo, kuquka ukuhluzwa.

3. Ziziphi iingenelo zeentsimbi ezinamaqhekeza?

Iingenelo zesinyithi esinezingxobo ziquka umlinganiselo ophezulu wendawo-to-volume, amandla omatshini, i-thermal kunye ne-conductivity yombane, kunye nokukwazi ukulungisa ubungakanani bepore kunye nokusabalalisa. Ezi zakhiwo zenza kube luncedo kwizicelo ezifana ne-catalysis, filtration, kunye nokugcinwa kwamandla.

4. Yiyiphi imida yesinyithi esinezingxobo?

Iintsimbi ezinamabhodlo zinokuba namandla asezantsi amaninzi xa kuthelekiswa neentsimbi ezingenazimbobo ngenxa yobukho be-voids ngaphakathi kwemathiriyeli. Ukongezelela, inkqubo yokuvelisa inokuba nzima kwaye ibiza.

5. Uthini umahluko phakathi kwesinyithi esivulekileyo kunye neeseli ezivaliweyo?

Iintsimbi ezivulekileyo zeeseli ezivulekileyo zinemingxuma edibeneyo efikelelekayo ukusuka kumphezulu wezinto eziphathekayo, ngelixa iintsimbi ezivaliweyo zeeseli ezivaliweyo ziye zatywinwa iipores ezingafikelelekiyo ukusuka phezulu.

6. Zeziphi iintlobo zesinyithi ezinokusetyenziswa ukwenza isinyithi esinemingxuma?

Iintsimbi ezinamabhodlo zingenziwa kuluhlu lwesinyithi, kubandakanya i-aluminiyam, i-titanium, i-nickel, ubhedu, kunye nentsimbi engatyiwa, phakathi kwabanye.

7. Yintoni usetyenziso lwesinyithi esinobukroti?

Iintsimbi ezinamanzi zinezicelo kumashishini afana ne-aerospace, ubunjineli be-biomedical, ukusetyenzwa kweekhemikhali, kunye nokugcinwa kwamandla, phakathi kwabanye.

8. Yeyiphi imingeni eyayanyaniswa nokuveliswa kweentsimbi ezinamanzi?

Imiceli mngeni eyayanyaniswa nokuveliswa kwesinyithi esinemingxuma ibandakanya ukugcina i-porosity efunwayo, ukuqinisekisa iimpawu ezifanelekileyo zomatshini, kunye nokulawula ubungakanani bepore kunye nokuhanjiswa.

9. Yintoni i-porosity yesinyithi esinemingxuma?

I-porosity yesinyithi edibeneyo inokuvela kwiipesenti ezimbalwa ukuya kwi-90% okanye ngaphezulu, kuxhomekeke kwiimfuno zesicelo.

10. Yintoni intsingiselo yobungakanani bepore kunye nokusabalalisa kwisinyithi esinemingxuma?

Ubungakanani bepore kunye nokusabalalisa kwisinyithi esinemingxuma kubalulekile ekumiseleni iimpawu zemathiriyeli, ezifana nokungena, amandla omatshini, kunye nommandla ongaphezulu. Oku kungenxa yokuba ubungakanani bepore buchaphazela indlela ulwelo olunokuqukuqela ngokulula ngayo kwimathiriyeli kunye nokuba ungakanani na umphezulu wendawo okhoyo ukwenzela ukusabela kwenzeke.

11. Ngaba iintsimbi ezinamaqhekeza zingenziwa ngokwezifiso kwizicelo ezithile?

Ewe, isinyithi esine-porous singenziwa ngokwezifiso kwizicelo ezithile ngokulungelelanisa ubungakanani bepore kunye nokusabalalisa, kunye nohlobo lwentsimbi esetyenzisiweyo.

12. Bubuphi ubomi besinyithi esinentunjana?

Ubomi besinyithi esine-porous buxhomekeke kwisicelo kunye nezinto ezithile ezisetyenzisiweyo. Ngokubanzi, iintsimbi ezinamaqhekezana zinobomi obude ngenxa yokuqina kwazo okuphezulu kunye nokuxhathisa ukubola.

13. Ngaba isinyithi esinemingxuma sinokuphinda sisetyenziswe?

Ewe, iintsimbi ezirhabaxa zinokuphinda zisetyenziswe ngokunyibilika phantsi kwaye ziphinde zisetyenziswe kwizicelo ezitsha.

14. Ngaba iintsimbi ezinamaqhekezana zikhuselekile ukuba zisetyenziswe kwi-biomedical applications?

Iindidi ezithile zesinyithi ezinamaqhekeza, ezifana ne-titanium kunye ne-tantalum, zihambelana ne-biocompatible kwaye zinokusetyenziswa ngokukhuselekileyo kwizicelo ze-biomedical. Isakhiwo se-porous sinokukhuthaza ukukhula kwamathambo kunye nokuphucula ukudibanisa kunye nezicubu ezijikelezayo.

15. Zinokuvavanywa njani iintsimbi ezinemingxuma kwiimpawu zazo?

Iintsimbi ezinamanzi zisenokuvavanyelwa iipropathi ezinje ngeporosity, ukungenwa, kunye namandla omatshini kusetyenziswa ubuchule obunje ngescan electron microscopy (SEM), uvavanyo lokungena kwegesi, kunye novavanyo loxinzelelo.

Fumanisa amathuba angenasiphelo esinyithi esinemingxuma! Ukusuka ekuphuculweni kokugqithiselwa kobushushu ukuya kuhluzo oluphuculweyo, iintsimbi ezinamanzi zibonelela ngeenzuzo ezizodwa ezinokuguqula ishishini lakho. Qhagamshelana nathi namhlanje ukuze ufunde ngakumbi kwaye uqalise ukujonga amandla esinyithi esinamathambo.

Yonke into oyifunayo ukunxibelelana HENGKO fumana isisombululo

Thumela umyalezo wakho kuthi: