-

Ukucocwa kwe-Biopharmaceutical kunye nokuhluza ipleyiti yokucoca i-porous 10um 20um 50um

Ipleyiti yokucoca enemingxuma luhlobo olutsha lwesixhobo sokuhluza esinezingxobo esiphakamileyo esenziwe ngentsimbi engatyiwayo ngumgubo ngokusefa, ukubumba, i-sinterin...

Jonga iinkcukacha -

I-Sintered Copper Bronze Plate yokuGunyisa

I-Deters Electrolysis kunye ne-Galvanic CorrosionYehlisa uphazamiseko lwe-RF kunye nokuphucula ukusebenza kwe-Electronics Ukwamkelwa ngcono kwizixhobo zakho ze-GPS, imozulu ...

Jonga iinkcukacha -

Sintered metal round deep filter sheets for imveliso yeoli ye-cannabis

Ukuhluzwa Kwimveliso yeemveliso ze-cannabinoid ezizinzile ukuhluzwa linyathelo elibalulekileyo. Ukususa i-wax, amafutha kunye neoli kwi-winterization ezininzi ...

Jonga iinkcukacha -

I-Stainless Steel Porous Metal Sheets SS316 Isihluzi sokusasazwa kwegesi yeHydrogen

I-Stainless Steel Porous Metal Sheets SS316 Isihluzo sokuDibaniswa kwerhasi yeHydrogen Ukuvula ukuguquguquka kwezinto eziNyenziwe ngeSintered Metal nge-HENGKO! Imeta yethu sintered...

Jonga iinkcukacha -

Iphepha leGas Diffusion Layers yeeMEAs, intsimbi engatyiwayo eneporous metal sintered / wire mesh ...

I-HENGKO iipleyiti zokucoca insimbi engenasici zenziwe nge-sintering 316L yezinto zomgubo okanye i-multilayer ye-wire mesh yensimbi engenasici kumaqondo obushushu aphezulu. Baye...

Jonga iinkcukacha -

Multi-layer sintered steel stainless steel mesh plate fluidized bed isixhobo Distributor bot...

Ipleyiti yentsimbi engenastainless yebhedi yolwelo Ukulawulwa kokuhanjiswa kwerhasi, ukuhanjiswa kwezinto ezinomgubo, kunye nokusebenza kolwelo kusetyenziswe ngokubanzi kwi-indu...

Jonga iinkcukacha -

I-316 304 ipleyiti yensimbi engenasici-Sintered porous metal filter media media

I-HENGKO izihluzi zepleyiti yensimbi engenasici zenziwe nge-sintering ye-316L yomgubo wezinto okanye i-multilayer ye-wire mesh yensimbi engenasici kumaqondo obushushu aphezulu. Baye...

Jonga iinkcukacha -

I-Corrosion resistant microns 316L intsimbi ecocekileyo ene-sintered filter sheet sheets / ...

Imveliso Chaza i-HENGKO i-porous metal diffusion layers lukhetho olukhokelayo kwi-electrolyzer ephezulu kunye nokusetyenziswa kweeseli zamafutha. Iyunifomu...

Jonga iinkcukacha -

IMicron eLula eCocekileyo enePorous SUS Sintered 316L iStainless Steel Inline yeMetal sheet Plate Rou...

Amashiti esinyithi afakwe i-sintered ane-porosity ephezulu afunyenwe kwi-metallic powders ngeendlela zokusasaza simahla ezilandelwa yi-sintering. Isakhiwo sintered...

Jonga iinkcukacha -

0.2 5 10 40 Micron porous sintered umgubo steel stainless 316L metal ipleyiti filter for c...

Iipleyiti ezixutyiweyo zezixhobo ezifunyenwe ngokwemaleko ngokusasazwa simahla, ukudityaniswa, kunye nomgubo wesinyithi osinyisayo zisetyenziswa njengemveliso engangesiqingatha sokufumana...

Jonga iinkcukacha -

Customized 2 10 20 60 Micron Porous Sintered Steel Stainless 316L Metal Plate Isihluzi

Amaphepha okucoca ubunzulu asetyenziselwa ukususa amasuntswana kulwelo. Oku kuthetha ukuba ulwelo lunokucaca-, lucoleke- okanye luhluzwe iintsholongwane. Amaphepha okucoca alungele...

Jonga iinkcukacha -

5 10 30 60 90 microns umgubo micro porous sintered metal sheet isihluzo

Amaphepha okucoca intsimbi asetyenziswa ngokubanzi ekususeni amasuntswana angaphandle kwiindidi ezininzi ezahlukeneyo zokuqukuqela kwemidiya. Iindawo ezisetyenziswa kakhulu: iigesi ngokubanzi,...

Jonga iinkcukacha -

I-HENGKO sintered steel stainless steel 316 yentsimbi erhabaxa yegesi yokusasazwa kwecwecwe lecwecwe le ...

Ipleyiti yokucoca intsimbi ye-HENGKO eyenziwe ngentsimbi engatyiwayo yenziwe ngeemaleko ezininzi zepaneli yocingo olulukiweyo kunye kusetyenziswa inkqubo yokucoca. Le nkqubo...

Jonga iinkcukacha -

Ibakala lezonyango micron intsimbi engatyiwa 316 316L wire mesh multi- umaleko ipleyiti / isihluzo disc...

Izihluzi ze-HENGKO ze-sintered wire mesh zinemigangatho emi-5 ye-mesh ene-sintered wire mesh enolwakhiwo oluzixhasayo lwamandla omatshini aphezulu kunye nobushushu obuphezulu...

Jonga iinkcukacha -

Amandla afanayo sintered metal porous micron filter fluidizers bronze ubhedu ifiliyi yobhedu...

Amaphepha okucoca ubunzulu asetyenziselwa ukususa amasuntswana kulwelo. Oku kuthetha ukuba ulwelo lunokucaca-, lucoleke- okanye luhluzwe iintsholongwane. Amaphepha okucoca alungele...

Jonga iinkcukacha -

Ulawulo lokuqukuqela kunye nokuhanjiswa ulwelo sintered ipleyiti yokucoca / sheet, umgubo sintered porous...

Amaphepha okucoca ubunzulu asetyenziselwa ukususa amasuntswana kulwelo. Oku kuthetha ukuba ulwelo lunokucaca-, lucoleke- okanye luhluzwe iintsholongwane. Amaphepha okucoca alungele...

Jonga iinkcukacha -

Iipleyiti zokucoca ubhedu/icwecwe elinobhobhozo lesinyithi elinobukrolo lokuhamba kunye nolawulo lwesandi

Amaphepha okucoca ubunzulu asetyenziselwa ukususa amasuntswana kulwelo. Oku kuthetha ukuba ulwelo lunokucaca-, lucoleke- okanye luhluzwe iintsholongwane. Amaphepha okucoca alungele...

Jonga iinkcukacha -

Isihluzi sesinyithi se-porous diski yesikwere se-micron sintered ishidi lokucoca ubhedu

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zibe nokucaciswa ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

hepa sintered ubhedu steel stainless steel icwecwe elinezingxobo zentsimbi yomatshini wokucoca umoya/oyile

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zibe nokucaciswa ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

Isiko lomgubo wentsimbi yefilter sheet microns porosity bronze sheets filter for wat...

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zibe nokucaciswa ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha

Iimpawu eziphambili zePlate yeMetal enePorous:

Iimpawu eziphambili zamaphepha esinyithi e-porous ziquka:

1.Ukuqina okuphezulu:

Amaphepha esinyithi enziwe ngentsimbi enziwe ngezinto ezomeleleyo njengentsimbi engatyiwa, titanium, okanye i-nickel alloys,

ukunika amandla agqwesileyo oomatshini kunye nokumelana nokubola, ukunxiba, kunye namaqondo obushushu aphezulu.

| Izinto eziphathekayo | Amandla oomatshini | Ukunyangwa kokuMhlwa | Nxiba ukuxhathisa | Ukumelana nobushushu | Usetyenziso |

|---|---|---|---|---|---|

| Yenziwe ngentsimbi eshayinayo | Phezulu | Phezulu | Phezulu | Kugqwesileyo (ukuya kuthi ga kwi-800°C) | Ukuhluzwa, ukusetyenzwa kweekhemikhali, i-oyile kunye negesi, amayeza |

| I-Titanium | Phakathi | Phezulu kakhulu | Phakathi | Kugqwesileyo (ukuya kuthi ga kwi-600°C) | I-Aerospace, iindawo zaselwandle, izicelo zonyango |

| I-Nickel Alloys | Phezulu kakhulu | Egqwesileyo | Phezulu | Kuphezulu (ukuya kuthi ga kwi-1000°C) | Ukuhluzwa kobushushu obuphezulu, ukusetyenzwa kweekhemikhali, ukuveliswa kwamandla |

2.Ulawulo oluchanekileyo loHluzo:

Ubungakanani be-pore obulawulwayo kunye nokusabalalisa okufanayo kuvumela ukuhluzwa okuchanekileyo, ukubonelela ngokuhambelana

ukusebenza kuluhlu olubanzi lwezicelo.

3.Customizable Porosity:

Amaphepha esinyithi anombhobho angenziwa ngokwezifiso ngokobungakanani bepore, imilo,

kunye nokusabalalisa, ukubonelela ukuguquguquka ukuhlangabezana neemfuno ezithile zokucoca okanye ukuhamba.

4.Ukuphumelela okuphezulu:

Naphezu kwamandla abo, amacwecwe ensimbi aneentsimbi avumela ukugqithiswa okuphezulu, ukuqinisekisa

Amazinga okuqukuqela okusebenzayo kweegesi kunye nolwelo ngelixa kugcinwe ukusebenza kakuhle kokucoca.

5.Ukuhambelana kweChemical:

La maphepha ahambelana noluhlu olubanzi lweekhemikhali, ukuzenza

ilungele ukusetyenziswa kwindawo ezinzima, kubandakanywa ukusetyenzwa kweekhemikhali kunye namashishini amayeza.

6.Ubushushu kunye nokuchasana noxinzelelo:

Izinto ezisetyenziswe kwiishiti zetsimbi ezinobuncwane ziyakwazi ukumelana nokugqithisa

amaqondo obushushu kunye noxinzelelo, ukuqinisekisa ukuzinza kunye nokuthembeka kwizicelo ezifunwayo.

7.Ukugcinwa okuphantsi kunye noBomi obude:

Amashiti esinyithi anamandla ahlala ixesha elide kwaye axhathise ukuvaleka,

ukunciphisa imfuno yokugcinwa rhoqo kunye nokutshintshwa, ngaloo ndlela bandise ubomi babo benkonzo.

8.I-Thermal kunye ne-Electric Conductivity:

Ukongeza kwi-filtration, ii-porous metal sheets zinokusebenza njenge-thermal

kunye nee-conductor zombane, ukwandisa uluhlu lwezicelo zabo.

Ezi mpawu zenza amacwecwe esinyithi angenabugorha alungele ukusetyenziswa kuhluzo, ulawulo lokuqukuqela, inkxaso yecatalyst,

kunye neenkqubo zokwahlula kumashishini ahlukeneyo, afana ne-aerospace, i-chemical processing, i-pharmaceuticals,

nobunjineli bokusingqongileyo.

Iindidi zePhepha leNsimbi leNsimbi ?

Ngokwenyani zimbini iindidi eziphambili zamashiti esinyithi angenabunwele onokuzifumana

kwimarike yamaphepha esinyithi avuzayo:

1. Amaphepha esinyithi adityanisiweyo:

Ezi zenziwe ngokudibanisa kunye ne-sintering powders zetsimbi. Iipores kula maphepha ziqhelekile

zidibene kwaye zinokwahluka ngobukhulu kunye nokumila. Amaphepha esinyithi e-sintered ahlala esetyenziswa kwizicelo

apho kufuneka amandla aphezulu kunye nokuhluzwa okulungileyo, njengakwizihluzi, izitshintshi zobushushu, kunye nezinto ezidambisa isandi.

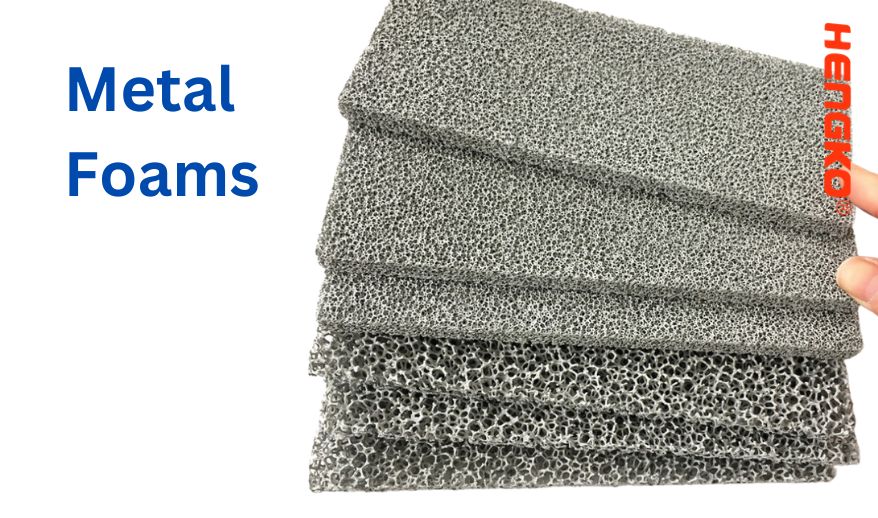

2. Amagwebu esinyithi:

Amagwebu esinyithi enziwa ngokuzisa amaqamza erhasi kwintsimbi enyibilikisiweyo aze ayivumele ukuba iqine.

Imingxuma kula maphepha ivalwa-iseli, nto leyo ethetha ukuba ayidityaniswanga. Amagwebu esinyithi anjalo

ehlala isetyenziswa kwizicelo apho kufuneka ukukhanya kunye namandla aphezulu, njengakwi-aerospace kunye

izicelo zeemoto.

Nazi ezinye iintlobo zamaphepha esinyithi avuzayo:

1. Umnatha wocingo olukiweyo:

Olu hlobo lomnatha lwenziwa ngokuluka ndawonye iingcingo ezibhityileyo. Ubungakanani bepore kumnatha wocingo olulukiweyo

inokulawulwa ngobungakanani beingcingo kunye nepateni yokuluka. Umnatha wocingo olulukiweyo ukholisa

esetyenziswa kwiziceloapho ukuhluzwa kunye neepropathi ezihamba kakuhle zifuneka khona, njengakwizikrini kunye nezihluzi.

2. Intsimbi eyandisiweyo:

Olu hlobo lwephepha lwenziwa ngokuqhawula ishidi eliqinileyo letsimbi kwipatheni ethile kwaye lisolule.

Imingxuma kwintsimbi eyandisiweyo idla ngokuba nde kwaye imile okwedayimane. Intsimbi eyandisiweyo ihlala

esetyenziswa kwiziceloapho kufuneka ubunzima obulula kunye namandla afanelekileyo, njengakunogada kunye neendlela zokuhamba.

Ukusetyenziswa kweSintered Porous Metal Sheet

I-Sintered metal sheets yimithombo yeendaba eguquguqukayo yokucoca ngenxa yeempawu zabo ezizodwa.

Nazi ezinye zezicelo onokuzisebenzisa:

* Ubume bobushushu obuphezulu:

* Ubume beMichiza eNcincisayo:

* Usetyenziso olunoxinzelelo oluphezulu:

*Imfuno yoLawulo lwaMasuntswana oluchanekileyo:

* Ukusebenziseka kwakhona kunye nokuHlaziya:

Kananjalo Nantsi eminye imizi-mveliso enokuthi ixhamle ngakumbi ekusebenziseni amacwecwe esinyithi adityanisiweyo kwiinkqubo zawo zokuhluza,

Ungajonga ukuba izakubalungile na kwindlela yakho okanye isixhobo ?

* Ukucutshungulwa kwemichiza - Kukuhluza ulwelo oluyonakalisayo kunye neegesi, kunye nezixhobo ezivela kwimisinga yenkqubo.

* Isiveliso saMandla - Ubushushu obuphezulu bokuhluzwa kweegesi kumaziko ombane.

* Ishishini loShishino-Ukuqinisekisa ubunyumba kunye nokucoceka kweemveliso ngokususa ibhaktheriya kunye namasuntswana.

* Ishishini lokutya kunye nesiselo - Ukucoca ukucacisa ulwelo, kunye nokususa amasuntswana angafunekiyo.

* Ukucocwa kwamanzi - Ukuba negalelo kwiinkqubo zokucoca ngokususa ukungcola emanzini.

Ngokubanzi, amashiti esinyithi afakwe i-sintered sisixhobo esibalulekileyo sokuhluza izicelo ezifuna ukuqina, ukumelana nobushushu obuphezulu, ukuhluzwa okuchanekileyo, kunye nokusebenziseka kwakhona.

FAQ

1. Yintoni aishidi lesinyithi elinobukroti, yaye yenziwa njani?

Ishidi lesinyithi elinobukroti luhlobo lwezinto ezibonakaliswe ngesakhiwo salo esingenasiphelo, esenziwe

i-pores edibeneyo okanye i-voids kubo bonke ubunzima bayo. La maxwebhu aveliswa ikakhulu

inkqubo eyaziwa ngokuba sintering. I-Sintering ibandakanya ukudibanisa umgubo wesinyithi kwi-mold kunye nokufudumeza

ingaphantsi kwendawo yayo yokunyibilika. Olu nyango lobushushu lubangela ukuba amasuntswana esinyithi adibane kunye ngaphandle kokunyibilikisa,

ukudala isakhiwo esiqinileyo kunye ne-porosity elawulwa ngokuchanekileyo.

Inkqubo ivumela ukwenziwa kwamaphepha anobungakanani bepore obahlukeneyo, imilo, kunye nokuhanjiswa,

elungiselelwe izicelo ezithile. I-Sintered steel stainless sheets, umzekelo, isetyenziswa ngokubanzi ngenxa

iimpawu zabo ezigqwesileyo mechanical, ukumelana umhlwa, kunye nokuzinza thermal.

2. Ziziphi ezona zicelo ziphambili zamaphepha ensimbi angenasici?

Iishiti zetsimbi ezingenasici zisetyenziswa kuluhlu olubanzi lwezicelo ngenxa yokuguquguquka kwazo kunye nokuqina.

Ezinye zezicelo eziphambili ziquka:

Uhluzo:

Isetyenziswe kwiinkqubo zombini zegesi kunye ne-liquid filtration, zisusa ngokufanelekileyo i-particulate matter

ngenxa yobukhulu bayo obuchanekileyo bepore.

* Ukunciphisa kunye nokusabalalisa:

Ilungele ukusabela kolwelo lwerhasi, i-aeration, kunye neenkqubo zokubilisa,apho kulawulwa khona

Ubungakanani beqamza bubalulekile.

* Ulwelo:

Uqeshwe kwiibhedi ezimanzi kwiinkqubo ezahlukeneyo zeekhemikhali, ezincedisa kwi-venukuhanjiswa

yeegesi ngolwelo okanye umgubo.

* Ukhuseleko lweSensom:

Ikhusela amacandelo anovakalelo kwindawo erhabaxa, ikhusela ungcoliseko

ngelixa uvumela unxibelelwano oluyimfuneko lokusingqongileyo.

* UkuBuyiselwa kwakhona kweCatalyst kunye neNkxaso:

Ibonelela ngeqonga eligqwesileyo lezinto zokuncedisa, ukuququzelela

ukuphendula kweekhemikhali ngelixa ivumela ukubuyiswa lula kwee-catalysts ezixabisekileyo.

3. Uwubona njani ubungakanani bepore obufanelekileyo kwisicelo esithile?

Ukumisela ubungakanani bepore obufanelekileyo kwisicelo esithile kubandakanya ukuqwalasela

izinto ezininzi, kuquka ubume ulwelo okanye iigesi ezicutshungulwayo, iintlobo

amasuntswana okanye ungcoliseko oluza kususwa, kunye nesantya sokuqukuqela esifunwayo. Kwizicelo zohluzo,

ubungakanani be pore bukhethwa ukuba bube buncinci kancinane kunelona lincinci isuntswana elifunekayo

ukuba ihluzwe ngaphandle. Kwizicelo ezibandakanya ukusasazwa kwerhasi okanye i-sparging, ubukhulu bepore buchaphazela

ubungakanani bamaqamza avelisiweyo, anokuthi abe nefuthe elibonakalayo ekusebenzeni kakuhle kwenkqubo.

Ukubonisana nabavelisi bephepha lesinyithi elinobukroti njenge-HENGKO banokubonelela ngemibono esekwe kwi

amava abanzi kunye nobuchule bobugcisa, ukuqinisekisa ukukhethwa kobukhulu bepore obufanelekileyo

kuso nasiphi na isicelo.

4. Ziziphi iingenelo ezinikezwa ngamashiti ensimbi angenasici ngaphezu kwezinye izinto?

I-Sintered steel stainless sheets inikezela ngeenzuzo ezininzi ngaphezu kwezinye izinto, zizenza a

ukhetho olukhethiweyo kwizicelo ezininzi zamashishini:

* Ukuqina:

Amandla abo aphezulu kunye nokuchasana nokunxiba kunye nokukrazula kuqinisekisa ubomi obude benkonzo phantsi kweemeko ezinzima.

* Ukuxhathisa ukuMnyama:

Ukuxhathisa umhlwa okwendalo yentsimbi yentsimbi ilungele ukusetyenziswa kwiindawo ezinobume bekhemikhali okanye

apho ukuchanabeka kwizinto ezidlekayo kuxhaphakile.

*Uzinzo lobushushu obuphezulu:

Ziyakwazi ukumelana namaqondo obushushu aphezulu ngaphandle kokuthotywa, zibenze zilungele ukusetyenziswa kutshintshiselwano lobushushu,

Izihluzi zobushushu obuphezulu, kunye nezinye izicelo ezifuna uzinzo lwe-thermal.

* Ukuhambelana kweMichiza:

Insimbi engenasici iyahambelana noluhlu olubanzi lweekhemikhali, ukunciphisa umngcipheko wokuthotywa kwezinto

kunye nokungcoliseka.

* Ukucoceka kunye nokuNzala:

Umphezulu wazo ogudileyo, ongenazimbobo unokucocwa lula kwaye ucocwe, kubalulekile kumayeza.

kunye nezicelo zokutya neziselo.

5. Ngaba amashiti ensimbi enziwe nge-stainless angenziwa ngokwezifiso kwizicelo ezizodwa?

Ewe, amashiti ensimbi enziwe ngentsimbi anokucwangciswa ngokubanzi ukuze ahlangabezane neemfuno ezizodwa zesicelo.

Ukwenza ngokwezifiso kunokubandakanya ukuhluka kobukhulu bepore, ubukhulu, ubungakanani beshiti, kunye nemilo, kunye nokufakwa

yezinto ezithile zokuxuba ukunyusa iipropathi ezithile ezinje nge-conductivity okanye ukumelana nobushushu.

Abavelisi abafana no-HENGKO basebenza ngokusondeleyo nabathengi ukuyila kunye nokuvelisa intsimbi yentsimbi

izisombululo ezihlangabezana ngokuchanekileyo neenkcukacha kunye neendlela zokusebenza ezifunekayo kwizicelo zabo.

Eli nqanaba lokwenza ngokwezifiso liqinisekisa ukuba imveliso yokugqibela inokusebenza ngokugqibeleleyo kwindawo ekujoliswe kuyo,

nokuba ibandakanya iimfuno zokuhluza ezizodwa, ukusetyenzwa kweekhemikhali ezikhethekileyo, okanye naluphi na olunye usetyenziso olungqale kwishishini.

Qhagamshelana noHENGKO

Ngaba ukulungele ukuphakamisa usetyenziso lwakho lwemizi-mveliso kunye nezisombululo zentsimbi ezirhabaxa?

Finyelela kuthi kuka@hengko.comkwaye masijike imingeni yakho ibe yimpumelelo.