-

3-90 micron ubhedu sintered kabini-evulekileyo iziphelo isihluzo ityhubhu yokucokisa kunye s...

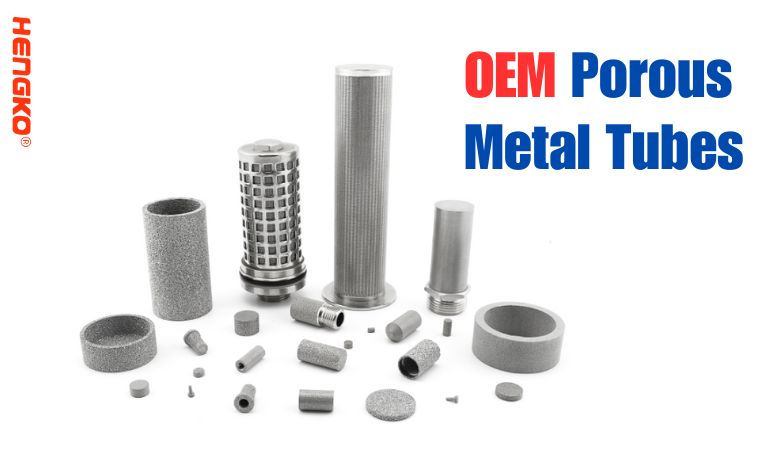

Iityhubhu zeHENGKO ezinabileyo zokucoca zinokuba nomngxuma okanye zingaboni kwaye zibenodonga olungqingqwa oluyi-1 mm. Zenziwe nge-isostatic compaction yomgubo kwi-mo eguquguqukayo ...

Jonga iinkcukacha -

iityhubhu zokucoca zesinyithi esinezingxobo sobhedu isilinda esinamanzi sokucoca umoya we-ptocess kunye...

Iityhubhu zeHENGKO ezinabileyo zokucoca zinokuba nomngxuma okanye zingaboni kwaye zibenodonga olungqingqwa oluyi-1 mm. Zenziwe nge-isostatic compaction yomgubo kwi-mo eguquguqukayo ...

Jonga iinkcukacha -

Iindibano ezikhohlakeleyo zetsimbi ezincinci ze-capillary filter ye-Thermal system yombhobho wobushushu...

Ulwakhiwo lwesinyithi esinezingxobo esine-porosity efanayo kakhulu siyakumpompa/kucime ulwelo olusuka kwindawo yolwelo ngesakhiwo sesinyithi esinentunja kwaye sisebenzise...

Jonga iinkcukacha -

I-3-90 ye-micron yesinyithi ye-bronze powder sintered filter cylinder tube ye-filtration system

Iityhubhu zeHENGKO ezinabileyo zokucoca zinokuba nomngxuma okanye zingaboni kwaye zibenodonga olungqingqwa oluyi-1 mm. Zenziwe nge-isostatic compaction yomgubo kwi-mo eguquguqukayo ...

Jonga iinkcukacha -

Custom 3 5 10 20 90 micron porous sintered metal isihluzo sobhedu cylinder ityhubhu yesilinda kushishino...

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zibe nokucaciswa ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha

Kutheni Usebenzisa Ityhubhu yeMetal enePorous?

Kukho izizathu ezininzi eziphambili zokuba kutheniityhubhu yensimbi ene-sinteredzisetyenziswa kwizicelo ezahlukeneyo:

Uhluzo:

* Umsebenzi wabo ophambili kukuhluza. Ubungakanani bepore obulawulwa ngokuchanekileyo bubavumela ukuba basuse ukungcola,

amasuntswana, kunye nezinto ezingcolisa ulwelo neegesi. Oku kungabalulekile kumashishini afana namayeza,

ukusetyenzwa kweekhemikhali, kunye nokutya kunye nesiselo, apho ubunyulu buyimfuneko.

* Ubungakanani bePore bunokususela kwi-submicron ukuya kwiimilimitha ezininzi, okubenza bakwazi ukuhluza uluhlu olubanzi lobungakanani bamasuntswana.

Ukuhamba okulawulwayo:

• Ulwakhiwo olunemingxuma luvumela ukuhamba okulawulwayo kolwelo kunye neegesi.

Oku kungasetyenziselwa i-aeration, ukuhanjiswa kwegesi, i-fluidization, kunye nezinye izicelo apho ulawulo oluchanekileyo lokuhamba luyimfuneko.

* Ukuhanjiswa kwepore efanayo kuqinisekisa ukuhamba okuhambelanayo kuyo yonke ityhubhu, ukuthintela umjelo kunye nokusabalalisa uxinzelelo olungalinganiyo.

Ukuqina kunye nokomelela:

* Yenziwe ngentsimbi enje ngentsimbi engatyiwa, nickel, okanye ubhedu, iityhubhu zetsimbi ezirhabaxa zomelele kwaye ziyakwazi ukumelana nokusebenza ngqwabalala.

iimeko, kuquka amaqondo obushushu aphezulu, uxinzelelo, kunye neendawo ezonakalisayo.

* Oku kubenza bafanelekele ukusetyenziswa ixesha elide kwizicelo ezifunwayo zemizi-mveliso.

Olunye uncedo:

• Iityhubhu zentsimbi ezinentunja nazo zikhaphukhaphu, zicocwa lula, kwaye zinokuphinda zisetyenziswe. Ziyakwazi ukwenziwa ngoomatshini ngokulula kwaye zenziwe zibe ziintlobo ezahlukeneyo,

ukwandisa ngakumbi ukuguquguquka kwazo.

Nantsi eminye imizekelo ethile yezicelo apho kusetyenziswa iityhubhu zetsimbi ezinentunja:

*Izahlulo zomoya:kwizityalo zokucoca amanzi amdaka ukwazisa ioksijini emanzini ukuze kukhule ibhaktiriya.

* Izihluzi zamafutha:ezimotweni nakwezinye iimoto ukususa ubumdaka kwipetroli.

* Ufakelo lwezonyango:ukwenzela ukungena kwamathambo kunye nokuhanjiswa kweziyobisi.

* I-Catalyst ixhasa:kwii-reactors zekhemikhali ukubamba kunye nokusabalalisa ii-catalysts.

* Izithulisi:kwiinkqubo zokukhupha ukunciphisa ingxolo.

Ekugqibeleni, izizathu ezicacileyo zokuba kutheni umntu enokukhetha ityhubhu yensimbi ene-porous ixhomekeke kwisicelo esithile

kunye neemfuno zayo. Nangona kunjalo, indibaniselwano yabo ekhethekileyo yokuhluza, ukuhamba okulawulwayo, ukuqina, kunye nezinye izibonelelo

zibenze zibe sisixhobo esixabisekileyo kuluhlu olubanzi lwamashishini.

Umsebenzi ongundoqo

Iityhubhu yensimbi ene-sinterediphantse yasebenza ngokufanayo nezinyeizihluzi zetsimbi zentsimbi or sintered metal sparger.

Umsebenzi oyintloko weetyhubhu zetsimbi ezinqabileyo kukubonelela ngokucokisekileyo kunye nokuthembekileyo, ukuhlukana kunye nokulawula

ukuhamba kwamanzi kunye negesi.

Ezi tyhubhu zentsimbi zenziwe ngexabiso le-316L SS amasuntswana entsimbi adityaniswe kunye ngokuntywila.

inkqubo, ukudala isakhiwo esinemingxuma edibeneyo. Iimpawu ezikhethekileyo zeetyhubhu zetsimbi ezinobuncwane

zivumela ukuba zisebenze imisebenzi emininzi ebalulekileyo:

1. Uhluzo:

Eyona njongo iphambili yeetyhubhu zetsimbi ezirhabaxa kukusebenza njengezihluzi, ukususa ukungcola, amasuntswana, kunye neengcoliseko ezisuka kulwelo kunye neegesi.

Ulawulo oluchanekileyo lobungakanani be-pore lubavumela ukuba bafezekise ukuhluzwa okulungileyo ukuya kumanqanaba e-submicron, ukuqinisekisa ukucoceka kwendawo eqhutyelwayo.

2. Ukusasazwa kweGesi kunye nolwelwe:

Iityhubhu zetsimbi ezinamaqhekezazisetyenziselwa ukusasaza iigesi okanye ulwelo ngokulinganayo nangokulinganayo. Ngokulawula ubungakanani bepore kunye nokusabalalisa,

banokudala indlela yokuhamba efanayo, ukukhusela umjelo kunye nokuphucula ukusebenza kakuhle kokusasazwa.

3. Ulwelo:

Kwiinkqubo zebhedi ezimanzi, ezi ityhubhu zisetyenziselwa ukukhupha amasuntswana aqinileyo, ukudala imeko efana neyolwelo emisiweyo.

Ukusasazwa okufanayo kwee-pores kunceda ekufezekiseni i-fluidization esebenzayo kunye nokulawulwa.

4. Ukungenisa umoya kunye nokuLinganisa koxinzelelo:

Iityhubhu zentsimbi ezinamanzi zisetyenziselwa ukukhupha iigesi, ukulinganisa uxinzelelo, okanye ukuthomalalisa iimeko zokufunxa kwiinkqubo ezahlukeneyo.

kunye nezixhobo. Benza ukudlula komoya okanye igesi ngelixa bethintela ukungena kwezinto ezingcolileyo.

5. Ukunciphisa ingxolo:

Kwezinye izicelo, iityhubhu zentsimbi ezinabileyo zisetyenziswa njengezithulisi okanye iimufflers ukunciphisa amanqanaba engxolo aveliswa kukuhamba kweegesi okanye ulwelo.

6. Ukusasazwa:

Iityhubhu zesinyithi ezinamazinyo ziququzelela inkqubo yokusasazwa kwerhasi okanye ulwelo ngokuvumela iimolekyuli ukuba zidlule kwimibhobho yazo edityanisiweyo.

Le propati ifumana isicelo kwiinkalo ezahlukeneyo, ezifana ne-catalysis kunye nemisebenzi yokudlulisa ubunzima.

7. Inkxaso kunye noKwabiwa:

Kumashishini athile, iityhubhu zetsimbi ezinamanzi zisebenza njengenkxaso yezakhiwo okanye ezinye izinto, ezibonelela ngokuzinza.

isakhelo kunye nokunceda ekuhanjisweni okufanayo.

Ngenxa ye-porosity ephezulu, ukuqina, ukuxhathisa kweekhemikhali, kunye nezakhiwo ze-pore ezilawulekayo, iityhubhu zetsimbi ezixhamlayo zifumana ubuninzi.

ukusetyenziswa kumashishini afana namayeza, iikhemikhali zepetroli, unyango lwamanzi, iimoto, i-aerospace, kunye nokunye okuninzi,

apho ukuhluzwa okusebenzayo kunye neenkqubo ezilawulwayo zokuhamba zibalulekile ekusebenzeni ngokugqibeleleyo kunye nokhuseleko.

Umgaqo wokuSebenza weSintered Porous Metal Tubes

Umgaqo-nkqubo wokusebenza kweetyhubhu zetsimbi ezine-sintered zisekwe kwiipropathi ezikhethekileyo zesakhiwo sesinyithi esine-sintered,

okuvumela ukuhluzwa okusebenzayo kunye nokulawulwa kokuhamba kwamanzi kunye neegesi. Nantsi isishwankathelo somgaqo wokusebenza:

1. Inkqubo yeSintering:

Iityhubhu zentsimbi ezinabileyo zenziwe ngenkqubo ebizwa ngokuba yi-sintering. Ibandakanya ukudibanisa amaqhekeza esinyithi, ngokuqhelekileyo

insimbi engenasici okanye ezinye ialloys zetsimbi, zibe kwimilo ethile, njengetyhubhu. Amasuntswana esinyithi afudunyezwa kwiqondo lobushushu

ngezantsi nje kwendawo yokunyibilika, kubangele ukuba zidibane, zenze uthungelwano oluluqilima noludityanisiweyo lwemibhobho.

2. Ulwakhiwo lwePore:

Iityhubhu zetsimbi ezine-sintered zinesakhiwo esichaziweyo se-pore ngenxa yokucwangciswa kweengqungquthela zetsimbi ngexesha lenkqubo ye-sintering.

Ubungakanani, imilo, kunye nokuhanjiswa kwezi pores kunokulawulwa ngokuchanekileyo ngexesha lokwenziwa kwemveliso ukuhlangabezana neemfuno ezithile zokuhluza.

3. Uhluzo:

Owona msebenzi uphambili weetyhubhu zetsimbi ezinentunjana ezinamanzi kukuhluza. Xa ulwelo okanye igesi idlula kwityhubhu, izinto ezingcolisayo,

amasuntswana, kunye nokungcola babanjwe ngaphakathi pores. Ubungakanani bepore yenzelwe ukuvumela ulwelo olufunwayo okanye irhasi ukuba idlule

ngelixa uvimba izinto ezingafunekiyo.

4. Ukusebenza kakuhle koHlulo:

Ukuhluza okusebenzayo kweetyhubhu zetsimbi ezine-sintered zixhomekeke kubukhulu bepore kunye nommandla opheleleyo okhoyo wokucoca.

Iisayizi ezincinci zepore zinokuthi zibambe amasuntswana acolekileyo, zibonelela ngokusebenza kakuhle kokucoca.

5. Ulawulo lokuqukuqela:

Isakhiwo esidibeneyo se-pore yeetyhubhu zetsimbi zetsimbi zenza ulawulo oluchanekileyo phezu kokuhamba kwamanzi okanye igesi. Ubungakanani kunye

Ukuhanjiswa kwee-pores kuchaphazela izinga lokuhamba kunye nokuhla koxinzelelo kwi-tube. Le propati ibalulekile kwizicelo

apho ukuhanjiswa okulinganayo kokuhamba okanye ukuhanjiswa kwamanzi okulawulwayo kuyadingeka.

6. Ukuqina kunye noKuxhathisa:

Iityhubhu zetsimbi ezisiyiweyo zihlala ziqinile kwaye zixhathisa kuxinzelelo lomatshini, iikhemikhali, kunye nobushushu obuphezulu. Ukucula

inkqubo iqinisekisa ukuba iincinci zetsimbi ziboshwe ngokuqinileyo, zibonelela ngokunyaniseka kwesakhiwo naphantsi kweemeko zokusebenza ezinzima.

7. Ukusebenziseka kwakhona kunye nokucoceka:

Iityhubhu zentsimbi ezinabileyo ezinabileyo zinokucocwa lula kwaye ziphinde zisetyenziswe. Banokumelana neendlela ezahlukeneyo zokucoca,

njengokuhlanjululwa kwe-backwashing, ukucocwa kwe-ultrasonic, okanye ukucocwa kweekhemikhali, ngaphandle kokuphazamisa ukusebenza kwabo kakuhle kokucoca.

Umgaqo osebenzayo we-sintered metal porous tubes ubenza ukuba bahluke kakhulu kwaye balungele uluhlu olubanzi

izicelo kumashishini afana nepetrochemicals, amayeza, unyango lwamanzi, i-aerospace, kunye nokunye. Bazi

zikhethwe ngokufanelekileyo ukuhluza, ukuqina, kunye nokukwazi ukumelana neemeko ezingqongileyo, ukubonelela ngokusebenza okuthembekileyo

kwiinkqubo ezibalulekileyo kunye neenkqubo.

Yintoni ekufuneka uyikhathalele i-OEM yeMibhobho yesinyithi yentsimbi?

Xa uqwalasela iityhubhu zentsimbi ezikhethekileyo ze-OEM zenkqubo yakho yokuhluza okanye iiprojekthi, zininzi

izinto ezibalulekileyo ekufuneka zithathelwe ingqalelo ukuqinisekisa ukusebenza ngokupheleleyo kunye nokuphunyezwa ngempumelelo.

Nantsi eminye imiba ephambili:

1. IiMfuno zoHluzo:

Cacisa ngokucacileyo iimfuno ezithile zokucoca kwisicelo sakho. Qinisekisa ukusebenza ngokufanelekileyo kokucoca,

ubungakanani bepore, kunye nesantya sokuhamba esifunekayo ukufezekisa iziphumo ezinqwenelekayo.

2. Iimpawu zolwelo okanye zerhasi:

Qonda iimpawu zolwelo okanye irhasi eza kuhluzwa, kubandakanywa ubushushu, uxinzelelo, i-viscosity, kunye neekhemikhali

ukuhambelana. Qinisekisa ukuba izinto ezikhethiweyo zetsimbi ze-porous ziyakwazi ukumelana neemeko zokusebenza ezijoliswe kuzo.

3. Ubungakanani bePore kunye noLwakhiwo:

Sebenza kunye nomvelisi we-OEM ukwenza ubungakanani bepore kunye nolwakhiwo lweetyhubhu zetsimbi ezinamaqhekeza ukuze zihambelane neyakho

iimfuno zesicelo. Qwalasela ubungakanani bamasuntswana ongcoliseko oluza kususwa kunye neempawu zokuqukuqela ezifunwayo.

4. Ukukhethwa kwezinto:

Khetha izinto ezifanelekileyo zetsimbi esekelwe ukumelana nemichiza yayo, iimpawu mechanical, kunye nokuhambelana

okuphakathi kuyahluzwa. Izinto eziqhelekileyo zibandakanya insimbi engenasici, ubhedu, i-nickel, kunye ne-titanium.

5. Uyilo kunye neJometri:

Sebenzisana nomvelisi we-OEM ukuyila imilo yetyhubhu kunye nemilinganiselo ukuze ilingane nenkqubo okanye iprojekthi yakho.

Qwalasela izinto ezifana nobude, idiameter, kunye nesiphelo soqhagamshelo ukwenzela ukudibanisa lula.

6. Ukusebenza kakuhle koHlulo kunye nokuLahla koxinzelelo:

Lungelelanisa ukusebenza kakuhle kokuhluza kunye nokuhla koxinzelelo kwiityhubhu zentsimbi ezirhabaxa. Ubuchule bokuhluza obuphezulu bunokuthi

kukhokelela ekunyukeni koxinzelelo, okunokuchaphazela ukusebenza kwenkqubo.

7. Ukucoceka kunye noLondolozo:

Xoxa ngokucoceka kunye neemfuno zokugcinwa kweetyhubhu zetsimbi ezinabileyo. Qinisekisa ukuba zinokucocwa lula

kwaye iphinde isetyenziswe ukwenza ngcono ubomi kunye nokunciphisa ixesha lokuphumla.

8. Ukwenza ngokwezifiso kunye nobuNgcali:

Sebenza kunye nomvelisi onamava we-OEM kunye nerekhodi eqinisekisiweyo ekuveliseni iityhubhu ezikhethekileyo zentsimbi.

Bamele babe nobuchule bokwenza iibhubhu ngokwezifiso ngokweemfuno zakho ezizodwa.

Ngokuqwalasela ngononophelo ezi zinto kunye nokusebenzisana ngokusondeleyo nomvelisi we-OEM, unokuqinisekisa ukuba

Iityhubhu zentsimbi ezikhethekileyo ze-OEM ziyilwe kwaye zilungelelaniswe ukuhlangabezana nenkqubo yakho yokuhluza okanye iimfuno ezizodwa zeprojekthi,

ekugqibeleni kukhokelela ekusebenzeni okuphuculweyo, ukuthembeka, kunye nokusebenza.

FAQ

1. Ziziphi iimpawu eziphambili zeetyhubhu zetsimbi ezine-porous sintered?

Iityhubhu zentsimbi ezinarhaxayo zibonelela ngeempawu ezininzi eziphambili ezenza zibe zizodwa kwaye zibe luncedo kakhulu kuzo

izicelo ezahlukeneyo. Ezi mpawu ziquka:

*UFanelo oluPhezulu loHlulo:

Ulawulo oluchanekileyo lobungakanani bepore luvumela ukuhluzwa okusebenzayo ukuya kumanqanaba e-submicron,

ukuqinisekisa ukususwa kwezinto ezingcolileyo kunye nokungcola kumanzi kunye neegesi.

*Ukuqina kunye nokomelela:

Inkqubo ye-Sintering idibanisa iincinci zetsimbi, inika amandla omatshini kunye nokuchasana

deformation, naphantsi kweemeko ezinzima.

*Iqondo lobushushu elibanzi kunye noxinzelelo loxinzelelo:

Iityhubhu zinokusebenza kwiindawo ezigqithiseleyo, zigcina ingqibelelo yesakhiwo kunye nokucoca

ukusebenza kakuhle kuluhlu olubanzi lwamaqondo obushushu kunye noxinzelelo.

*Ukuhambelana kweMichiza:

Ziyakwazi ukungena kwikhemikhali kwaye ziyamelana nokuhlwa, zizenza zilungele ukuhluzwa ngokunamandla

iikhemikhali kunye nemidiya eyonakalisayo.

*Ukucoceka kunye nokuSetyenziswa kwakhona:

Iityhubhu zetsimbi ezine-porous sintered zinokucocwa ngokulula kwaye ziphinde zisetyenziswe ngamaxesha amaninzi, ukunciphisa ukugcinwa

iindleko kunye nokwandisa ubomi besihluzi.

2. Zisebenza njani iityhubhu zentsimbi ezinabileyo njengezihluzi?

Ukusebenza kweetyhubhu zetsimbi ezinabileyo njengezihluzi zisekwe kulwakhiwo oludityanisiweyo lwepore.

Xa i-fluid okanye igesi ihamba nge-tube, ukungcola kunye neengqungquthela zifakwe ngaphakathi kwee-pores

ngelixa uvumela isiphakathi esifunekayo ukuba sidlule. Ubungakanani, ukuhanjiswa, kunye nokucwangciswa kweepores

misela ukusebenza kakuhle kokucoca kunye nohlobo lweengqungquthela ezinokususwa. Intsimbi ene-sintered iphezulu

I-porosity kunye neepores ezintle zivumela ukuhluzwa okusebenzayo, okwenza ezi ityhubhu zilungele izicelo ezibalulekileyo apho

Uhluzo oluchanekileyo noluthembekileyo luyafuneka.

3. Ziziphi izinto eziqwalaselwayo ngokufakela iityhubhu zetsimbi ezine-porous sintered kwinkqubo?

Ufakelo olululo lubalulekile ukuqinisekisa ukusebenza ngokukuko kweetyhubhu zetsimbi ezinabileyo. Ezinye izinto eziqwalaselwayo ziquka:

*Utywino olufanelekileyo:

Qinisekisa uqhagamshelo olukhuselekileyo kunye nokuvuza okungavuziyo kuzo zombini iziphelo zetyhubhu ukuthintela ukudlula kunye nokugcina ukusebenza kakuhle kokucoca.

*Uqhelaniso:

Misa ityhubhu ngokuchanekileyo ukuqinisekisa ukuba isikhokelo sokuhamba sihambelana nomsebenzi owenziweyo, nokuba kukucoca, ukukhupha umoya, okanye ukukhupha amanzi.

*Inkxaso kunye noKhuselo:

Ukubonelela ngenkxaso eyaneleyo kunye nokukhuselwa ukukhusela umonakalo kwiibhubhu ngexesha lofakelo kunye nokusebenza.

4. Zeziphi izicelo ezinokuthi zisetyenziswe iityhubhu zetsimbi ezinamanzi?

Iityhubhu zetsimbi ezinamanzi zifumana izicelo kuwo wonke amashishini ahlukeneyo, kubandakanya:

Iikhemikhali zePetroli kunye nokusulungekiswa:Ukufumana inkxaso ye-catalyst, ukuhluzwa kolwelo lwenkqubo, kunye nezicelo zokusasazwa kwegesi.

Amachiza:Kwindawo yokungena umoya ongenanto, ukuhluzwa kwerhasi, kunye neenkqubo zokuhanjiswa kweziyobisi.

Unyango lwamanzi:Ukucocwa kwamanzi amdaka, ukuphefumla, kunye nokuhluzwa kwamanzi okusela.

I-Aerospace:Kwiinkqubo zamafutha kunye ne-hydraulic yokuhluza kunye nokukhupha umoya.

Iimoto:Kulawulo lokukhutshwa, ukuhluzwa kwamafutha, kunye neenkqubo zokuthambisa.

Ukutya kunye nesiselo:Ukwenzela isiselo se-carbonation, i-aeration, kunye nokuhluzwa komphunga.

5. Iityhubhu zetsimbi ezinabombhobho zinegalelo njani ekusebenzeni kakuhle kwenkqubo kunye nokusebenza?

Iityhubhu zetsimbi ezinebhobhobhobho ziphucula ukusebenza kakuhle kwenkqubo kunye nokusebenza ngoku:

*Ukuqinisekisa ukusebenza kakuhle kokucoca, okukhokelela kulwelo olucociweyo nolucocwe ngakumbi okanye iigesi.

*Ukubonelela ngokusasazwa kokuhamba okufanayo, ukuthintela umjelo okanye ukuhanjiswa koxinzelelo olungalinganiyo.

*Ukumelana neemeko ezinzima, ukunciphisa ixesha lokuphumla kunye neendleko zokugcina.

*Ukuququzelela ukusasazwa kwerhasi kunye neenkqubo zokwenziwa kolwelo, ukwenza ngcono ukuphendula kweekhemikhali kunye nokusebenza kogqithiso lobuninzi.

6. Ngawaphi amanyathelo okulawula umgangatho asetyenziswayo ngexesha lokwenziwa kweetyhubhu zetsimbi ene-porous sintered?

I-HENGKO njenge-Top Sintered Metal Filter abavelisi baphumeza amanyathelo angqongqo olawulo lomgangatho kuyo yonke inkqubo yokuvelisa. Oku kuquka:

*Umgangatho weMpahla: Ukusebenzisa amasuntswana esinyithi akumgangatho ophezulu wokuqinisekisa amandla omatshini kunye nokumelana neekhemikhali.

*Ulawulo lobungakanani bePore: Ulawulo oluchanekileyo lweeparamitha ze-sintering ukufezekisa ubungakanani obufunwayo bepore kunye nokuhanjiswa.

*Ukuchaneka koMda: Ukuqinisekisa ukunyamezelana okuqinileyo ukuhlangabezana neenkcukacha zabathengi.

*Uvavanyo lokuSebenza: Ukuqhuba iimvavanyo zobuchule bokuhluza, uvavanyo lokwehla koxinzelelo, kunye novavanyo lwamandla oomatshini.

Ungalibazisi ukufikelela kuthi ukuze ufumane iingcebiso kunyemasikuncede wenze ngcono inkqubo yakho yokucoca okanye iprojekthi.

Sithumele i-imeyileka@hengko.comngoku kwaye uthathe inyathelo lokuqalangokubhekiselele kwimpumelelo eyongeziweyo kunye nokusebenza nge

Umgangatho weHENGKOItyhubhu yentsimbi ene-sintered.