-

Umenzi weSihluzi seDiskhi esinePorous Metal eSintered kwi-line yoMenzi-HENGKO

I-HENGKO yenza iiwasha ezisecaleni zeVenus, iKitty, iKlasi, kunye neembiza zikaMusa Moka. Iphakheji ibandakanya iwasha kunye nepleyiti yokucoca ikofu. Idayamitha yeGasketNceda...

Jonga iinkcukacha -

Sintered sintered steel stainless 316L intsimbi imelana nobushushu obuphezulu cylinder yokucoca umoya...

Imveliso Chaza i-HENGKO intsimbi yesihluzo sentsimbi ecocekileyo yenziwe nge-sintering 316L yemathiriyeli yomgubo okanye i-multilayer yensimbi engenasici yocingo olunemesh kubushushu obuphezulu...

Jonga iinkcukacha -

I-HENGKO sintered steel stainless 316L yentsimbi enomoya yokucoca indebe yetaper esebenzisa iwax kwi-3d ...

Imveliso Chaza i-HENGKO intsimbi yesihluzo sentsimbi ecocekileyo yenziwe ngokufaka i-sintering 316L yemathiriyeli yomgubo okanye i-multilayer yensimbi engenasici yocingo olunemesh kubushushu obuphezulu...

Jonga iinkcukacha -

Sintered metal stainless steel 316L bronze porous air filtration filter cylinder / ikhandlela

Ukwazisa izihluzi zeKhandlela ze-HENGKO: Izisombululo eziLungisiweyo kwiiMfuno zakho zokuHlufa kwimizi-mveliso! Iimpawu zeMveliso:-UHluzo oluLungileyo: Izihluzi zethu zekhandlela zi ...

Jonga iinkcukacha -

Iikomityi zetsimbi ezinabileyo ezinabileyo zokucoca imilo yepompo ye-hydraulic, intsimbi engatyiwa yintsimbi 60-90 mic...

Inkcazo yeMveliso I-HENGKO Sintered amakhandlela okucoca kunye neekhatriji zisilinda okanye izinto ezimilise okwe-cap yokucoca ngamanye amaxesha zibizwa ngokuba ziikomityi zokucoca ezisiyiweyo, ezi ...

Jonga iinkcukacha -

Micron replacement sintered steel stainless steel porous metal filter disc

Ukwazisa iHENGKO's High-Stainless Steel Sintered Porous Metal Filters I-HENGKO ngumvelisi okhokelayo wentsimbi engatyiwa sintered metal porous f...

Jonga iinkcukacha -

D6.1 * H1.6 20um sintered metal esinezingxobo icwecwe disc stainless steel

Ukwazisa i-HENGKO's Sintered Filtered Disc: Vula Amandla oHluzo oluchanekileyo! Ngaba ujonge idiski yokucoca i-sintered ebonelela ngokuhlukileyo...

Jonga iinkcukacha -

Umnikelo okhethekileyo 30-45 / 50-60um sintered steel stainless indebe isihluzo sekomityi kunye nomnqamlezo kwi ...

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zibe nokucaciswa ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

I-30-45 / 50-60um yentsimbi ecocekileyo yentsimbi efakwe kwikhatriji yesihluzi sentsimbi yokubamba ilangatye

Isibambisi somlilo sisixhobo esifakwe ekuvuleni kwendawo ebiyelweyo, okanye kumbhobho odibanisayo kwindlela yokuvala. Bavumela iigesi okanye umphunga ukuba uf...

Jonga iinkcukacha -

I-D9.5 * H9.5 60-90um icwecwe lecwecwe lentsimbi lecwecwe elisetyenziselwa ukuhluza ulwelo

Ukwazisa izihluzi zediski ze-HENGKO sintered, esona sisombululo kuzo zonke iimfuno zakho zokuhluza! Izihluzi zethu zediski ze-sintered ziyilelwe ukubambisa iindawo eziqinileyo ...

Jonga iinkcukacha -

isihluzi sentsimbi ye-disc yomthengisi endaweni ye-microns sintered porosity umgubo wesinyithi...

I-Sintered Porous Metal Diss. ifana nesiponji sesinyithi. IiFilter zeMetal ezinePorous Sintered zibandakanya iyunifomu ephezulu, uthungelwano oludityanisiweyo lweepores ezinetor...

Jonga iinkcukacha -

Izinto zokucoca umgubo we-Sintered / iikomityi zesihluzi zesinyithi ezinabileyo / iisilinda

I-HENGKO i-stainless steel filter iityhubhu zenziwe nge-sintering 316L yomgubo wezinto okanye i-multilayer ye-wire mesh yensimbi engenasici kumaqondo obushushu aphezulu. Bakhe ba...

Jonga iinkcukacha -

Multi-layer sintered steel stainless steel mesh plate fluidized bed isixhobo Distributor bot...

Ipleyiti yentsimbi engenastainless yebhedi yolwelo Ukulawulwa kokuhanjiswa kwerhasi, ukuhanjiswa kwezinto ezinomgubo, kunye nokusebenza kolwelo kusetyenziswe ngokubanzi kwi-indu...

Jonga iinkcukacha -

micron porous powder sintered metal steel stainless filter cartridges

Izihluzi zetsimbi ezine-sintered kunye neetyhubhu ezinama-porous zinde, izihluzi zecylindrical ezineendonga ezibhityileyo, oko kukuthi, zinomlinganiselo ophezulu wobude ukuya kububanzi. Isihluzi sesinyithi esinencambu...

Jonga iinkcukacha -

Isampulu yeSampuli yoHlalutyi iSintered Steel Stainless Gas Isampulu yeSampuli

Isampulu yerhasi ye-HENGKO ingasetyenziselwa ukusampula kwegesi rhoqo kumxholo wothuli oluphezulu, amaqondo obushushu kunye nokufuma. Isihluzo sokuqala: Ekungeneni...

Jonga iinkcukacha -

I-316 304 ipleyiti yensimbi engenasici-Sintered porous metal filter media media

I-HENGKO izihluzi zepleyiti yensimbi engenasici zenziwe nge-sintering ye-316L yomgubo wezinto okanye i-multilayer ye-wire mesh yensimbi engenasici kumaqondo obushushu aphezulu. Baye...

Jonga iinkcukacha -

Porous metal ss sintered isihluzi disc kunye nesantya sokuqukuqela fast for micron-ubungakanani ukuhluza ap...

Ukwazisa izihluzi ze-HENGKO ze-Sintered Disc: Ukukhulula amandla oHlulo oluPhezulu! Xa isiza kuhluzo olusebenzayo, izihluzi zediski ze-HENGKO ze-sintered ...

Jonga iinkcukacha -

vacuum KF certering umsesane kunye Sintered Metal Filter

Imveliso ichaza i-Flange Connections Centreing rings with Sintered Metal Filter in vacuum technology isetyenziswe ukuya kuluhlu oluphezulu lwe-vacuum ye-10 ukuya kwi-7 mbar...

Jonga iinkcukacha -

Inkqubo ekhethekileyo sintering microns steel stainless steel porous cups filter elements

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zibe nokucaciswa ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

Ukuqukuqela kokungena micron intsimbi engatyiwayo ngumgubo sintered isilinda sokucoca inqwelo moya

Izinto zokucoca intsimbi ye-HENGKO zenziwe nge-sintering 316L yemathiriyeli yomgubo okanye i-multilayer yentsimbi yentsimbi enomnatha kumaqondo obushushu aphezulu. Banenyosi...

Jonga iinkcukacha

Kutheni Khetha iSinteredIsinyithi IzihluzikwiiProjekthi zakho zokuHlunga:

Izihluzi zetsimbi zentsimbizenziwe ngomgubo wesinyithi ocinezelweyo kwaye udityaniswe (uhlanganiswe) ukwenza i-porous;

isakhiwo esiqinileyo. Ezi zihluzo zaziwa ngokomelela kwazo okuphezulu, ukuqina, kunye nokukwazi ukuhluza amasuntswana amancinci kakhulu.

Iimpawu ezi-8 eziphambili zeSintered Metal Filters

I-HENGKO ibonelela ngoluhlu lweemveliso zokucoca ngetsimbi, kubandakanya intsimbi engatyiwayo, ubhedu oludityanisiweyo,

Umnatha onesinki, kunye nezihluzo ze-titanium ezisinkiweyo, izihluzi zesinyithi zomgubo, isihluzo sesinyithi esine-sinterediidiski, kwaye sintered stainless

intsimbiimibhobho. Izihluzi zethu zenzelwe usetyenziso olufuna amanqanaba aphezulu okuchasana nomhlwa, ubushushu obuphezulu,

kunye nokusebenza okuchanekileyo okuphezulu.

1. Amandla aphezulu:

Izihluzi zetsimbi zetsimbi zenziwe kwi-metal powders, ezibanika amandla aphezulu

kunye nokuqina.

2. Ukumelana nobushushu obuphezulu:

Izihluzi zetsimbi ezisinki zikwazi ukumelana namaqondo obushushu aphezulu, zizenze

ilungele indawo ezinobushushu obuphezulu.

3. UKuxhathisa uKutya:

Izihluzi zetsimbi ezisinkiweyo ziyamelana nokubola kwaye zingasetyenziselwa ukudleka

iindawo ezingqongileyo.

4. Ukumelana neMichiza:

Izihluzi zetsimbi zetsimbi zixhathisa uninzi lweekhemikhali, zizenza zilungele imichiza

ukusetyenzwa kwezicelo.

5. Ukusebenza kakuhle kokucoca:

Izihluzi zetsimbi zetsimbi zinesakhiwo esihle kakhulu se-pore, esivumela ukuba

hluza amasuntswana amancinci kakhulu ngempumelelo.

6. Umthamo ophezulu wokubamba ubumdaka:

Izihluzi zetsimbi ezisiyiweyo zinomthamo ophezulu wokubamba ubumdaka, okuthetha ukuba zinako

hluza umthamo omkhulu wolwelo phambi kokuba utshintshwe.

7. Ukucoca ngokulula:

Izihluzi zetsimbi ezine-Sintered zinokucocwa ngokulula kwaye ziphinde zisetyenziswe, zizenze zingabizi kakhulu

ekuqhubekeni.

8. Ukuguquguquka:

Izihluzi zetsimbi ezine-Sintered zingenziwa kwiimilo ezahlukeneyo kunye nobukhulu ukuhlangabezana neemfuno ezithile

yezicelo ezahlukeneyo.

Kwizihluzi zetsimbi ezinobukroti, intsimbi engenasici lukhetho olufanelekileyo lokuhluza kwimichiza, ukucokisa i-petroleum,

ukuveliswa kwamandla, imveliso yamayeza, kunye nezinye izicelo.

Ku-HENGKO, zonkeizihluzo ze-sinteredUvavanyo lomgangatho ongqongqo phambi kokuhanjiswa, kubandakanya ukusebenza kakuhle kokucoca

kunye nokuhlolwa okubonakalayo. Izihluzi zethu zetsimbi ezine-sintered zinokusebenza okuphezulu kokususa amasuntswana, ukuxhathisa ukubola, kuncinci

ukuhla koxinzelelo, ukucocwa lula, kunye neenzuzo backwash xa kuthelekiswa nabanye abathengisi metal filter.

Ukuba iminikelo yethu yangoku ayihlangabezani neemfuno zakho zokucoca, ncedaQhagamshelana nathingezinto zakho, ubukhulu,

kunye neemfuno zesicelo.

Ukusetyenziswa kweIsihluzo seSinteredIimveliso

Izihluzi ze-Sintered zisetyenziswa kuluhlu olubanzi lwamashishini, kubandakanywa ukusetyenzwa kweekhemikhali, ukucocwa kwepetroleum, ukuveliswa kwamandla, kunye nemveliso yamayeza. Zikulungele ukusetyenziswa kwizicelo apho umgangatho ophezulu wokuhluza ufuneka, kwaye apho isihluzi kufuneka sikwazi ukumelana nokushisa okuphezulu, uxinzelelo kunye neendawo ezinobungozi. Ezinye zezona nkqubo zixhaphakileyo zeemveliso zokucoca zibandakanya:

Ukucoca ulwelo

Izihluzo zetsimbi zetsimbi ziqhele ukusetyenziselwa ukuhluza ulwelo kumashishini ahlukeneyo. Ziluncedo kakhulu kwizicelo apho ulwelo oluhluzwayo lune-viscous okanye lunenqanaba eliphezulu lezinto eziqinileyo. Izihluzi ze-Sintered zinokususa amaqhekeza amancinci njenge-1 micron, ezenza zibe zilungele ukusetyenziswa kwizicelo apho kufuneka umgangatho ophezulu wokucoca.

I-Fluidizing

Izihluzi zetsimbi ze-Sintered zingasetyenziselwa ukusetyenziswa kwe-fluidizing, apho zinceda ukusasaza ngokulinganayo igesi okanye ulwelo ngokhuko lwamasuntswana aqinileyo. Oku kubaluleke kakhulu kwizicelo ezifana ne-catalysis, apho kubalulekile ukuqinisekisa ukuba zonke ii-reactants zisasazwa ngokulinganayo.

Ukuqhawula

Izihluzi zetsimbi zetsimbi zingasetyenziselwa ukusetyenziswa kwe-sparging, apho zinceda ukwazisa igesi kulwelo. Oku kuluncedo kakhulu kwizicelo ezifana nokubiliswa, apho kubalulekile ukuqinisekisa ukuba ulwelo oluvundisiweyo lunomoya opholileyo.

Ukusasazwa

Izihluzi zetsimbi ezisiyiweyo zinokusetyenziselwa ukusetyenziswa kokusasazwa, apho zinceda ngokulinganayo ukusasaza irhasi okanye ulwelo ngenwebu. Oku kubaluleke kakhulu kwizicelo ezifana neeseli ze-fuel, apho kubalulekile ukuqinisekisa ukuba i-reactants isasazwa ngokulinganayo kwi-membrane.

I-Flame Arrestor

Izihluzo zetsimbi ezisiyiweyo zinokusetyenziswa njengezithinteli zomlilo, apho zinceda ukunqanda ukusasazeka kwamadangatye okanye ugqabhuko-dubulo. Oku kubaluleke kakhulu kwizicelo ezifana nezixhobo zokucoca okanye izityalo zamachiza, apho izinto ezinokutsha zikhona.

Ukuhluzwa kwegesi

Izihluzi zetsimbi zetsimbi nazo zisetyenziselwa ukuhluza igesi kuluhlu olubanzi lwezicelo zoshishino. Ziluncedo ngokukodwa kwizicelo apho igesi ehluzwayo iqulethe inqanaba eliphezulu lokufuma okanye ezinye izinto ezingcolileyo. Izihluzi ze-Sintered zinokususa amaqhekeza amancinci njenge-0.1 micron, ezenza zibe zilungele ukusetyenziswa kwizicelo apho kufuneka umgangatho ophezulu wokucoca.

Ukutya kunye nesiselo

Izihluzi zetsimbi zetsimbi zikwasetyenziswa kwiintlobo ngeentlobo zokutya neziselo, kubandakanywa ukuhluzwa kwebhiya, iwayini, kunye nezinye iziselo. Ziluncedo ngokukhethekileyo kwizicelo apho umgangatho ophezulu wokuhluza ufuneka, kwaye apho isihluzo kufuneka sikwazi ukumelana nokushisa okuphezulu kunye neendawo ezinobungozi.

Ukuba ufuna imveliso yokucoca i-sintered ehlangabezana nemathiriyeli ethile, ubukhulu, okanye iimfuno zesicelo, nceda uzive ukhululekile ukuQhagamshelana nathiukuxoxa ngeemfuno zakho.

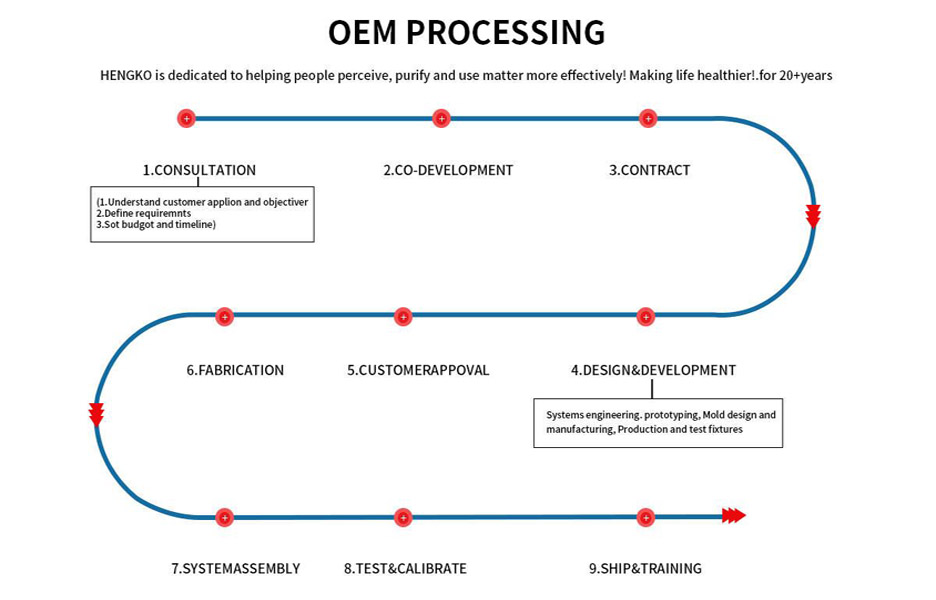

Lungiselela Inkqubo yeSintered Metal Filter

Wamkelekile ukuthatha iimfuno zakho zoyilo olukhethekileyo izihluzi ukuze uqhagamshelane nathi, siya kufumana esona sisombululo sokucoca

iimfuno zakho zokuhluza. kwayeunokulandela inkqubo ebanzi yokuqinisekisa ukuba imveliso yokugqibela idibana

zonke iinkcukacha eziyimfuneko. Inkqubo ibandakanya:

1.Uthethwano kunye noQhagamshelwano HENGKO

2. UPhuhliso ngokubambisana

3. Yenza iSivumelwano

4. Uyilo noPhuhliso

5. Imvume yoMthengi

6. Ukwenziwa/Ukuveliswa kobuninzi

7. Indibano yenkqubo

8. Vavanya kwaye ulinganise

9. Ukuthumela kunye nokuFakela

Ukuba ufuna imveliso yokucoca i-sintered edibana nemathiriyeli ethile, ubukhulu, okanye iimfuno zesicelo,

nceda uqhagamshelane nathi ukuxoxa ngeemfuno zakho.

Yintoni eyahlula i-HENGKO kuShishino lwesihluzi sesinyithi seSintered?

Kutheni ukhetha izihluzi zentsimbi ze-HENGKO eziSintered?

Izihluzi zetsimbi ze-HENGKO zentsimbi zijongwa kakhulu ngabathengi bethu ngobungakanani obukhethekileyo bokubamba ubumdaka kunye nobomi obude.

Zenziwe ngenkqubo yokucoca elawulwa ngobuchule, ezi zihluzo ze-OEM Sintered Metal zibonelela ngeepores ezisasazwe ngokufanayo.

ngomlinganiselo wemicronukusuka kwi-0.1μ ukuya kwi-100μ, iqinisekisa ukuhluzwa okuchanekileyo nokuthembekileyo.

Uncedo olungundoqo lwe-HENGKO's Sintered Metal Filters:

1.Uyilo oluZinzileyo kunye noLomeleleyo:

Izihluzi zethu zigcina imilo ezinzileyo ngokuxhathisa okugqwesileyo kwimpembelelo kunye nemithwalo etshintshanayo,

ukubenza bomelele kakhulu naphantsi kweemeko ezinzima.

2.Umoya oPhelelekayo oPhezulu:

Ngokusebenza ngokufanelekileyo kokucoca, izihluzi zethu zetsimbi zetsimbi zibonelela ngokugqwesa komoya,

ukuqinisekisa ukusebenza ngokugqibeleleyo kwizicelo ezahlukeneyo.

3.Amandla aphezulu kunye noKuxhathisa ukuMhlwa:

Ziyilelwe ukumelana noxinzelelo oluphezulu kunye neendawo ezinobungozi kakhulu, izihluzi zethu zibonelela ngamandla akhethekileyo othutho,

ibenza ukuba balungele ukusetwa kwemizi-mveliso ebango.

4.Ubushushu obuphezulu bokusebenza:

Ilungele ukuhluzwa kwerhasi yobushushu obuphezulu,

Izihluzi zethu zetsimbi zentsimbi zisebenza ngokuthembekileyo kwiindawo ezigqithisileyo.

5.Ukhetho lokuLungisa:

Sinikezela ngezisombululo ezilungelelanisiweyo ezinoluhlu olubanzi lwezixhobo, iimilo, kunye nobukhulu bonxibelelwano ukuhlangabezana neemfuno ezithile zesicelo.

Njengomvelisi ohloniphekileyo e-China, i-HENGKO igxile ekuveliseni izihluzi zetsimbi eziphucukileyo.

Iqela lethu labachwephesha abaqeqeshiweyo lizinikele ekuphuhliseni nasekuveliseni ukusebenza okuphezulu

sintered steel stainless kunye nemathiriyeli porous.

Yamkelwa ngokuzingca njengeshishini lobuchwepheshe obuphezulu, i-HENGKO isebenzisana neeyunivesithi eziphambili zombini ekhaya.

nakumazwe ngamazwe ukuba siqhubeke sivelisa izinto ezintsha kunye nokuphucula iimveliso zethu.

Iingcebiso ezi-4 Xa ukhetha & ne-OEM eSintered Isihluzi seMetal kufuneka Ukhathalele

Kukho iindlela ezininzi zokwenza izihluzo zetsimbi ezisikiweyo ukuze zihlangabezane neemfuno ezithile zosetyenziso.

Ezinye iindlela eziqhelekileyo ziquka:

1. Ukukhetha isinyithi esifanelekileyo:

Iintsimbi ezahlukeneyo zineempawu ezahlukeneyo ezinokuchaphazelaukusebenza kwe

isihluzo sesinyithi esine-sintered. Umzekelo, insimbi engenasici i-corrosion-resistant kwaye inendawo ephezulu yokunyibilika, ngelixa

I-aluminiyam ikhaphukhaphu kwaye ine-conductivity elungileyo yombane.

2. Ukuchaza ubungakanani bepore kunye nokumila:

Iifilitha zetsimbi ze-Sintered zingayilwa kunye neepores zobukhulu obuhlukeneyo kunye

iimilo ukuze zilungele iimfuno ezahlukeneyo zokuhluza. Umzekelo, isihluzi esine pores ezincinci siya kusebenza ngakumbi ekususeni

amasuntswana amancinane, ngelixa isihluzi esine pores ezinkulu sinokufaneleka ngakumbi kumazinga aphezulu okuhamba.

3. Ukutshintsha ukutyeba kwemidiya yokucoca:

Ubukhulu besihluzo seendaba nazo zinokuhlengahlengiswa ukuze zihambelane nokuthe ngqo

iimfuno zesicelo. Imithombo yeendaba eshinyeneyo inokubonelela ngokusulungekileyo ngokusulungekileyo kodwa inokubangela ukuba phezulu

ukuhla koxinzelelo kunye nokunciphisa amazinga okuhamba.

4. Ukulungelelanisa ubushushu kunye neemeko zoxinzelelo:

Izihluzi zetsimbi zetsimbi zinokuthi ziyilwe ukuba zimelane ngokuthe ngqo

ubushushu kunye neemeko zoxinzelelo, kuxhomekeke kwisicelo. Kubalulekile ukuqwalasela ezi zinto xa

ukukhetha icebo lokucoca ukuqinisekisa ukuba linokumelana neemeko zokusebenza zesixokelelwano.

Ukwenza isihluzo sesinyithi esine-sintered ukuhlangabezana neemfuno zakho ezithile, dibana nenjineli enamava

okanye ingcali yobugcisa kwintsimi inokuba luncedo. Banokukhokela uyilo olufanelekileyo kunye nokukhethwa kwezinto eziphathekayo ngokusekelwe

kwiimfuno ezithile zesicelo.

FAQyeSintered Metal Filters

1. Yintoni iSintered Metal Filter?

Ingcaciso emfutshane yesihluzo sesinyithi esisikiweyo:Sisihluzo sesinyithi esisebenzisa amasuntswana omgubo wesinyithi alingana nobungakanani bamasuntswana

ukubunjwa sisitampu, ubushushu obuphezulu sintering yinkqubo yokwenziwa kwesinyithi kusetyenziswa ubungakanani obungumgubo.

imizimba yeentsimbi ezahlukeneyo kunye ne-alloys emva kokunyathela.

I-Metallurgy yenzeka ngokusasazwa kumaqondo obushushu angaphantsi kwendawo yokunyibilika yeziko lobushushu obuphezulu. Iintsimbi kunye nealloys

ezisetyenziswa ngokuxhaphakileyo namhlanje ziquka ialuminiyam, ikopolo, nickel, ubhedu, intsimbi engatyiwa, kunye netitanium.

Kukho iinkqubo ezahlukeneyo ongazisebenzisa ukwenza umgubo. Ziquka ukucola, ukuzenzela, kunye nokubola kweekhemikhali.

Iinkcukacha ezingakumbi malungaYintoni iSintered Metal filter, nceda uhambe kwaye ujonge eli nqaku lethu.

2. Kutheni Usebenzisa iStainless Steel Metal ukwenza isihluzo?

Ukukhetha i-Stainless Steel Metal njengezona zixhobo ziphambili, ngenxa yokuba zinezibonelelo ezininzi zentsimbi engenasici

1. Akukho lula ukugqwala

2. Ubushushu be-sintering akufuneki bube phezulu kakhulu

3. Iipores zilula ukulawula ngexesha lokutshisa

4. Ukubumba i-Sintered yomelele ngakumbi kwaye akukho lula ukukhubaza

5. Kulula ukuyicoca

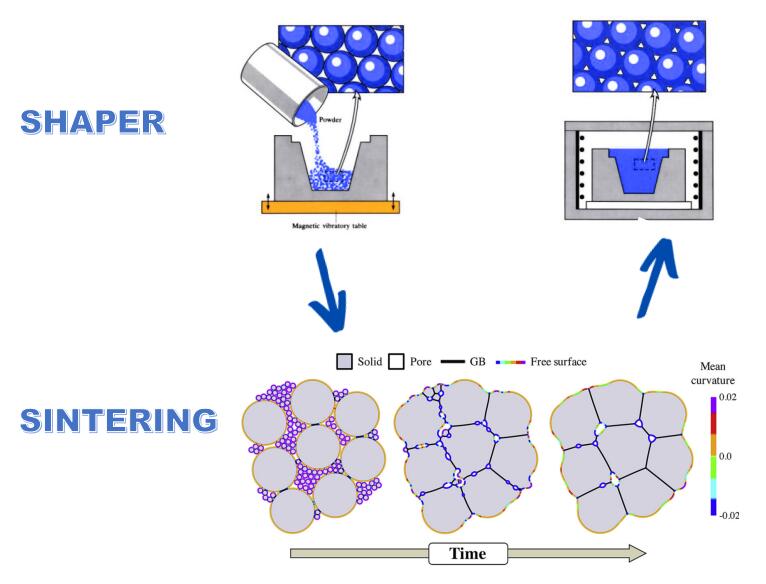

3. Senziwa njani iSintered Metal Filter?

Kwinkqubo yokwenziwa kwe-Sintered metal filter, eziphambili zinamanyathelo ama-3 ngolu hlobo lulandelayo:

A: Inyathelo lokuqala kukufumana intsimbi yamandla.

Umgubo wesinyithi, Ungafumana umgubo wesinyithi ngokusila, ukuzenzekelayo, okanye ukubola kweekhemikhali. Unokudibanisa isinyithi enye

umgubo kunye nenye isinyithi ukwenza i-alloy ngexesha lenkqubo yokwenziwa, okanye ungasebenzisa umgubo omnye kuphela. I-advanteji yokucula yileyo

ayitshintshi iipropati ezibonakalayo zezinto zetsimbi. Inkqubo ilula kangangokuba izinto zetsimbi azitshintshwa.

B: Isitampu

Isinyathelo sesibini kukuthululela i-powder yensimbi kwi-mold elungiselelwe ngaphambili apho unokubumba khona isihluzo. Indibano yokucoca yenziwe kwigumbi

iqondo lobushushu naphantsi kwesitampu. Ubungakanani boxinzelelo olusetyenziswayo luxhomekeke kwintsimbi oyisebenzisayo, njengoko iintsimbi ezahlukeneyo zine-elasticity eyahlukileyo.

Emva kwempembelelo yoxinzelelo oluphezulu, i-powder yensimbi ihlanganiswe kwi-mold ukwenza isihluzo esiqinileyo. Emva kwenkqubo yempembelelo yoxinzelelo oluphezulu, unako

beka isihluzo sesinyithi esilungisiweyo kwiziko lobushushu obuphezulu.

C: Ubushushu bobushushu obuphezulu

Kwinkqubo ye-sintering, iinqununu zetsimbi zixutywe ukuze zenze iyunithi enye ngaphandle kokufikelela kwindawo yokunyibilika. Le monolith yomelele,

eqinile, kunye ne-porous isihluzo njengesinyithi.

Ungalawula i-porosity yesihluzo ngenkqubo ngokwenqanaba lokuhamba komoya okanye ulwelo oluza kuhluzwa.

4. Yintoni iNkqubo yokuSintering?

Inyathelo elinye elibalulekileyo yiSintering, ngoko ke yintoni inkqubo yokucoca kwaye ibe zizihluzi zentsimbi?

Unokujonga njengetshathi yokulandela ukuqonda ngokucacileyo.

5. Ziziphi iiNkcazo eziPhambili zeSintered Metal Filter?

Emva kwenkqubo yokufaka isitampu kunye nobushushu obuphezulu be-sintering, sinokufumana izihluzi zetsimbi zetsimbi, emva koko zingene

ukuze sazi umgangatho wezihluzo ze-sintered, ngokwesiqhelo, siya kuvavanya ezinye iinkcukacha zezihluzi, ukuba idatha iyafikelela.

iimfuno njengoko abathengi becela, emva koko sinokukhulula ukulungiselela ukuthunyelwa ngaphandle.

1. I-Porosity

2. Uvavanyo loxinzelelo

3. Uvavanyo lokuhamba (igesi kunye nolwelo)

4. Uvavanyo lwesitshizi setyuwa (uvavanyo lokunqanda umhlwa)

5. Umlinganiselo wembonakalo yobukhulu

Ukuba usathanda ukwazi ngakumbi malungaSintered umgaqo wokusebenza wokucoca, nceda ujonge yethu le blog khangela iinkcukacha.

B:IsiceloyeSintered Metal Filter

6. Uphi usetyenziso lweSintered Metal Filters?

Njengoko abaxumi bethu bebhekisa kusetyenziso oluphambili lwesihluzo se-sintered ngolu hlobo lulandelayo:

1.) Ukucoca ulwelo2. Ulwelo

3. Ukuhlambalaza4. Ukusasazwa

5. Flame Arrestor6. Ukuhluzwa kwegesi

7. Ukutya kunye nesiselo

7. Ngaba ndingasebenzisa izihluzi zeMetal eziSintered ezineentlobo ezininzi zeeoyile?

Ewe, kodwa kufuneka wenze ubungakanani obukhethekileyo bepore njengeoyile, kunye nemfuneko yolawulo lokuhamba, ke

ungakwamkela kuQhagamshelana nathiukuze usazise iinkcukacha zakho.

8. Ngaba iSintered Metal Filter ingaqhubeleka nokusebenza Nokuba iimeko ziBanda?

Ewe, kwisihluzo sesinyithi esine-sintered, njenge-316Lsintered isihluzo sentsimbiingasebenza phantsi

-70 ℃~ +600℃ , ngokokuninzi lwesihluzo esisiyiweyo sinokusebenza phantsi komkhenkce. kodwa kufuneka uqinisekise

Ulwelo kunye nerhasi inokuhamba phantsi kwemeko yokukhenkceza.

9. Loluphi uhlobo lweMichiza enokuthi luhluze ngezihluzo zeMetal eziSintered kwaye ngaphandle kokonakalisa uMzimba wesihluzi?

Sivavanya uninzi lweekhemikhali ezinokushukunyiswa kule mveliso ngaphandle kokuyenzakalisa,

ezifana nephenol zinikwe ukuba zenziwe kusetyenziswa izinto eziqinileyo zokunganyangeki ngamachiza.

1. ) Iasidi

I-acids ezinamandla: ziquka i-sulfuric acid (H2SO4), i-nitric acid (HNO3), kunye ne-hydrochloric acid (HCl).

Ii-acids ezibuthathaka kwiindawo eziphezulu, ezifana ne-acetic acid

B Izisombululo ze-Lewis ze-asidi ezineempawu ezizodwa zeekhemikhali, ezifana ne-zinc chloride

2.) Iziseko ezomeleleyo:

kuquka i-sodium hydroxide (NaOH) kunye ne-potassium hydroxide (KOH)

Iintsimbi zealkali (ezifana nesodium) kwimeko yazo yesinyithiIalkali kunye nealkaline emhlabeni metal hydrides

Uxinzelelo oluphezulu lweziseko ezibuthathaka ezifana ne-ammonia

3.) Iiarhente zokukhupha amanzi emzimbeni,

kubandakanywa ne-sulfuric acid ephezulu, i-phosphorus pentoxide, i-calcium oxide,

i-zinc chloride (engekho isisombululo), kunye nezinto zetsimbi zealkali

4.) Ii-oxidizing agents ezinamandla,

kuquka ihydrogen peroxide, i-nitric acid, kunye ne-asidi yesulfuric egxininisiweyo.

5.)Iihalojeni zombane

ezifana ne-fluorine, i-chlorine, i-bromine, kunye ne-iodine (i-ion ye-halides ayidleki),

kunye neetyuwa ze-electrophilic ezifana ne-sodium hypochlorite.

6.) I-Organic halides okanye i-halides ye-organic acids, njenge-acetyl chloride kunye ne-benzyl chloroformatei-anhydride

7.)ii-alkylating agentsnjenge-dimethyl sulfate

8.) Ezinye iikhompawundi eziphilayo

10. Indlela yokuCoca iiFilter zeMetal eziSintered?

Ukucoca ngokufanelekileyo kubalulekile ukugcina ukusebenza kunye nexesha elide lokucoca isinyithi esine-sintered.

Ngokuxhomekeke kwisicelo-nokuba yeyegesi okanye ukuhluzwa kolwelo-iindlela ezahlukeneyo zokucoca zinokusetyenziswa:

1.Blowback for Gas Applications:

*Kwiinkqubo zokuhluza irhasi, i-blowback yindlela eqhelekileyo esetyenziselwa ukucoca izihluzo zetsimbi ezine-sintered.

Le nkqubo ibandakanya ukubuyisela umva ukuhamba kwerhasi ngesihluzi, ukukhupha amasuntswana avalelekileyo,

kunye nokucoca imidiya yokucoca.

2.Umva kwizicelo zolwelo:

* Kwiinkqubo zokucoca ulwelo, ukubuyisela umva yindlela esebenzayo yokucoca. Le nkqubo ibuyisela umva ukuhamba kolwelo ngesihluzo ukususa ungcoliseko oluqokelelweyo kunye nokubuyisela ukusebenza kwesihluzo.

3.Ukucoca ngeUltrasonic:

*Ukucoca ngeUltrasonic kusetyenziswa ukususa imathiriyeli engasebenziyo ngokwekhemikhali kwisihluzo. Le ndlela isebenzisa amaza omsindo we-high-frequency ukwenza ama-bubbles microscopic kwisisombululo sokucoca, esikhupha ngokufanelekileyo kwaye sisuse ukungcola kwindawo yokucoca.

4.Ukucoca ngamachiza:

Ukususa ukungcola okunenkani, iindlela zokucoca iikhemikhali zingasetyenziswa. Oku kunokubandakanya:

*Ukucoca isinyibilikisi:

Ukusebenzisa izinyibilikisi ezifanelekileyo ukunyibilikisa nokususa izinto ezingcolisekileyo eziphilayo.

*Ukuhlamba okuCaustic:

Ukusebenzisa izisombululo ze-alkaline ukudiliza kunye nokususa izinto eziphilayo kunye ne-inorganic.

*Ukuhlamba ngeAcidi:

Izisombululo ze-Acidic zisetyenziselwa ukunyibilikisa iidiphozithi zamaminerali okanye i-oxides.

Amanzi kunye noGutyulo loMoya:

Indibaniselwano yamanzi kunye nokugungxulwa emoyeni kungasetyenziselwa ukususa iintsalela kunye nokuqinisekisa ukuba isihluzo sicocwe kakuhle.

Ezi ndlela zokucoca zinceda ukwandisa ubomi beefilitha zetsimbi ze-sintered, ziqinisekisa ukuba ziyaqhubeka nokubonelela ngokufanelekileyo

kunye nokuhluzwa okuthembekileyo kwizicelo ezahlukeneyo.

C:Ulwazi lweodoloISintered Metal Filter

11

Ewe okuqinisekile .

Singakwazi i-OEM yeSintered Metal Filters njengoluhlu lwakho olulandelayo lweemfuno zoluhlu:

1. Ubungakanani bePore

2. Umlinganiselo weMicron

3. Inqanaba lokuHamba

4. Imidiya yokuhluza oya kuyisebenzisa

5. Nabuphi na ubungakanani njengoyilo lwakho

11. Yintoni i-MOQ kwi-Wholesale sintered isihluzo sesinyithi esivela kwi-HENGKO?

NjengoMvelisi weSihluzo soBuchule obuSintered, sinohlobo oluthile lokhetho olufana neDisc Sintered Filters,

I-Sintered Filters Tube,Ipleyiti yeSintered Filtered, iSintered Filters Cup,I-Sintered Filters Mesh, malunga ne-MOQ

iya kusekelwa kwakhoUbungakanani boyilo kunye nobukhulu bepore njl, isiqhelo i-MOQ yethu imalunga ne-200 -1000pcs / into esekelwe kuyilo.

12. Yintoni eyenza ukuba izihluzi zentsimbi ze-HENGKO zihluke?

1.) Iifilitha zetsimbi ze-HENGKO ze-sintered zihlukaniswa ngokusetyenziswa kweubuchule bobunini

esiqinisekisa ubungakanani bepore obungaguquguqukiyo kunye nemfezeko yobume obukhethekileyo.

2.) Ngaphezu koko, i-HENGKO inikezela ngokubanziiinketho zokwenza ngokwezifiso, evumela abathengi ukuba balungelelanise

i-porosity, imathiriyeli, kunye noyilo ukuze luhambelane ngokugqibeleleyo neemfuno zabo zesicelo.

Into yokuphonononga :

1. Ukujongwa koMhlophelo:UHluzo lweGesi yoShishino

UkuSebenza okuPhuculweyo kuHluzo lweGesi yoShishino kunye nezihluzo zeMetal zeSintered ezenziwe ngokwezifiso

Umngeni:

Iplanti yokucoca igesi kwimizi-mveliso ijongene nemiba ngokuncipha kobuchule kwinkqubo yayo yokuhluza,

okukhokelela ekugcinweni rhoqo kunye nexesha lokuphumla elingalindelekanga.

Izihlungi ezikhoyo azikwazanga ukuphatha umthwalo ophezulu we-particle, obangele ukuvala kunye nokunciphisa izinga lokuhamba.

Isisombululo:

Iingcali ze-HENGKO zicebise ukuba kutshintshe izihluzo ezikhoyo kunye nezihluzo zentsimbi ezenzelwe ukwenziwa

kwizicelo zomthwalo wamasuntswana aphezulu. Ezi zihluzo zibonise ubume bepore obuphuculweyo kunye nokuqina okongeziweyo,

yenzelwe ngokukodwa ukujongana neemfuno zokuhluzwa kwerhasi yamashishini.

Iziphumo:

Izihluzi zetsimbi ezitsha zadityaniswa ngokungenamthungo kwinkqubo ekhoyo, zinciphisa kakhulu ukuvala

imiba kunye nokugcinwa rhoqo.

Izihluzo eziphuculweyo zibonelele ngokunyuka kwe-30% kwisantya sokuhamba kunye nokuphucula ukusebenza kwenkqubo iyonke.

Ngokwamkela izihluzi zentsimbi ze-HENGKO zesiko, umzi-mveliso wokwenza irhasi wafumana uphawu

ukuphuculwa kobuchule bokuhluza, ixesha elide lokucoca ulwelo, kunye nokuncipha kwexesha lokusebenza.

Isisombululo asizange siphucule imveliso kuphela kodwa sibe negalelo ekusebenzeni kweendleko eziphantsi ngokunciphisa

iindleko zokulondolozwa kunye nokuqinisekisa ukusebenza kwenkqubo okungaphazanyiswa.

Usenemibuzo kwaye uthanda ukwazi iinkcukacha ezithe vetshe kwiISintered Metal Filter, Nceda uzive ukhululekile ukuQhagamshelana nathi ngoku.

Kwakhona UnakoSithumele i-imeyileNgqo Ngokulandelayo:ka@hengko.com

Siza kuthumela umva ngeeyure ezingama-24, enkosi ngesigulana sakho!