I-Sintering idlala indima ebalulekileyo kwishishini lemveliso, ivumela ukuveliswa kwezinto ezintsonkothileyo nezihlala ixesha elide. Ukuqonda izinto ezisisiseko zokucula kubalulekile kwiinjineli, abaphandi, nakubantu abanomdla ngokufanayo. Eli nqaku lijolise ekungeneni kwingqikelelo ye-sintering, ukuphonononga inkqubo yayo, ukuxoxa ngezicelo zayo, kwaye iqaqambise iingenelo kunye nemida yayo.

Yintoni iSintering?

I-Sintering yinkqubo ebandakanya ukudibanisa imathiriyeli engumgubo ibe bubunzima obuqinileyo ngokufaka ubushushu. Ngokungafaniyo neenkqubo zemveli zokunyibilika, i-sintering ayifikeleli kwindawo yokunyibilika kwezinto. Endaweni yoko, isebenzisa ukusasazwa kwee-athomu kuwo wonke amasuntswana, nto leyo ekhokelela ekudibaneni nasekuxinaniseni. Le nkqubo iphumela kwisakhiwo esiqinileyo esineempawu eziphuculweyo zomatshini.

I-Sintering nayo inengqiqo ebanzi kunye nemxinwa. Kwingqiqo ebanzi, i-sintering yinkqubo yokuba umgubo okhululekileyo udityaniswe kwiibhloko ngamandla okudibanisa okuqinileyo kwiqondo lokushisa elithile. Kodwa i-sintering kwintsimi yokwenza i-iron yinkqubo edibanisa umgubo wentsimbi kunye nezinye izinto eziqulethe isinyithi kwi-metallurgical performance block artificial block by fusion, imveliso yayo yi-sinter. Zibandakanya iinkqubo ezahlukeneyo zephysicochemical Nangona bobabini basebenzisa igama elithi sintering.

Inkqubo yeSintering

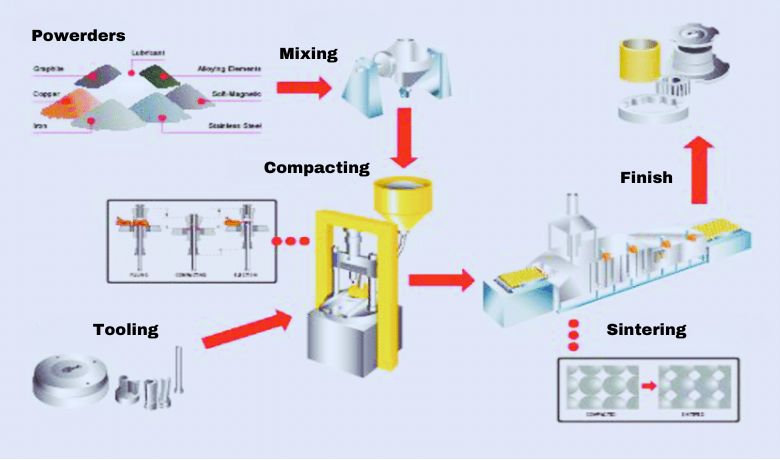

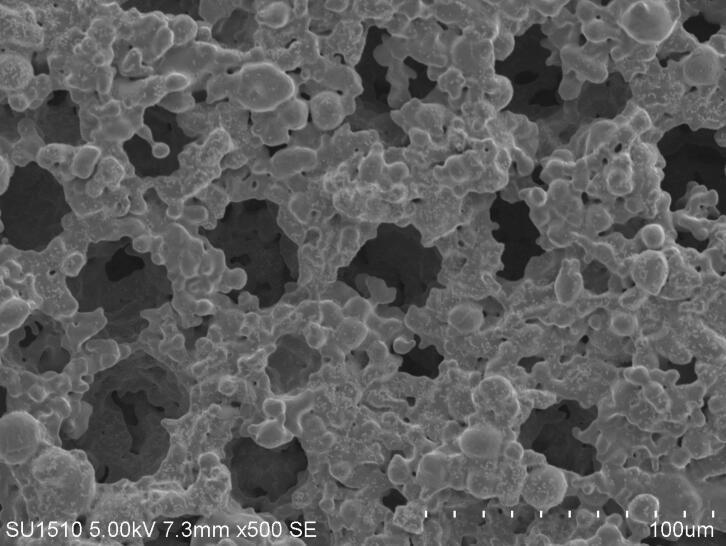

Inkqubo ye-sintering inezigaba ezininzi. Ekuqaleni, izinto eziluhlaza zenziwe ngendlela ethile, ngokuqhelekileyo ngendlela yepowder. Lo mgubo udityaniswe kusetyenziswa uxinzelelo ukuqinisekisa ukufana kunye nokuphelisa i-voids. Emva koko, izinto ezidibeneyo ziphantsi kokushisa okulawulwayo kwisithando somlilo. Ubushushu bulawulwa ngononophelo ukuququzelela ukudibanisa amasuntswana ngaphandle kokubangela ukunyibilika okupheleleyo. Ngethuba lokufudumala, iinqununu zihamba ngokusasazwa, ezikhokelela ekubunjweni kwentamo kunye noxinaniso. Inqanaba lokugqibela libandakanya ukupholisa imveliso ye-sintered, ukuyivumela ukuba iqiniswe ibe yinto eqinile kunye nesakhiwo esidibeneyo.

I-powder sintering besisithi ngumgubo wesinyithi okanye umgubo. Yinkqubo yobugcisa bokufumana izinto eziphathekayo okanye imveliso kumandla afunekayo kunye nezinto ezikhethekileyo ngenxa yokubambisana ngokomzimba kunye neekhemikhali phakathi kwamaqhekeza kwiqondo lokushisa elingaphantsi kwendawo yokunyibilika yecandelo eliphambili. I-HENGKO inothotho lweemveliso zokutshiza ngomgubo weentlobo ezahlukeneyo zokucaciswa kunye nobukhulu kubandakanyaisihluzi sediski, isihluzo sekomityi,isihluzo sekhandlela,isihluzo sephephakwaye nangokunjalo. Imveliso yethu ye-sintering steel stainless ine-advanteji yamandla aphezulu, i-Good permeability, Ukuchaneka okuchanekileyo kokucoca kunye nokuchasana nokugqwala, ngokufanelekileyo kwiindawo ezininzi. Inkonzo elungiselelwe wena nayo iya kunikezelwa njengoko ucelile.

Inyathelo ngalinye kwinkqubo ye-sintering yintsebenziswano, kwaye ugxininiso linyathelo elibaluleke kakhulu kwinkqubo yokuntywila, ke ithetha ukuthini i-concentrate?Ukugxininiswa linyathelo elithatha inyathelo lokwandisa imathiriyeli ekrwada kunye ne-fuel, iyenze ibe ngumthwalo weziko elihlangabezana Iimfuno zokuqinisa ukucocwa komlilo oqhumayo phambi kokuba izinto ezikrwada kunye nepetroli zingene kwisithando somlilo. Iimpawu eziphezulu zobugcisa kunye nezoqoqosho kunye neenzuzo zezoqoqosho zingafumaneka emva kokuba i-concentrateis isetyenziswe kwi-blast furnace smelting. Yintoni ebizwa ngokuba "yisebenzise kakuhle yonke into" kwaye usebenzise izixhobo ezifanelekileyo. Kwakhona luhlobo lokuqonda ukonga kunye nokukhuselwa kwendalo.

Izinto ezichaphazela iSintering

Izinto ezininzi zinefuthe kwinkqubo ye-sintering, kubandakanywa ubushushu, izinga lokufudumeza, uxinzelelo, ubungakanani bamasuntswana, kunye nokwakheka. Ubushushu budlala indima ebalulekileyo ekumiseleni i-sintering kinetics kunye neziphumo zezinto eziphathekayo. Izinga lokufudumeza lichaphazela inkqubo yoxinaniso, njengoko ukufudumeza ngokukhawuleza kunokukhokelela ekudibaneni kwamasuntswana angalinganiyo. Uxinzelelo lusetyenziswa ngexesha lokudibanisa ukunyusa ukulungiswa kwakhona kwe-particle kunye nokuphelisa i-porosity. Ubungakanani besuntswana kunye nokwakheka kunempembelelo kwindlela yokuziphatha yokuntywila, kunye namasuntswana amancinci kunye nokwakheka okufanayo okukhuthaza uxinaniso olungcono.

Ngokwembono yokoqobo yegama elithi sintering, igama elithi ukutshisa kukusebenzisa umlilo, kufuneka kubekho ilangatye elikhatshwa bubushushu obuphezulu. Kwaye inkqubo ye-sintering kufuneka yenziwe kumaqondo obushushu aphezulu. Ubushushu obuphezulu benziwa ngokutshiswa kwamafutha. Uluhlu lweqondo lokushisa, isantya esivuthayo, ububanzi bebhendi evuthayo, i-atmospheric kwi-sintered material, njl njl kuya kuchaphazela ukuqhubela phambili kwenkqubo ye-sintering kunye nomgangatho weemveliso ezigqityiweyo zokugqibela. Kwaye ezo zinto zinxulumene neempawu zomzimba kunye neekhemikhali zamafutha kunye nedosi. Ngoko ke, iimpawu zoMzimba kunye neekhemikhali zamafutha ziyinto ebalulekileyo echaphazela inkqubo ye-sintering.

Isafobe into ayinakho ukubakho ngaphandle kwesiseko abahlala phezu kwayo. Amafutha kunye nezinto ezikrwada ziyafana nolusu kwaye iinkuni ezinobudlelwane ziyimfuneko. Ngaphandle kwayo nayiphi na enye, Inkqubo ye-sintering ayinakwenzeka. Kodwa i-Sintered fuel ikakhulu ibhekisa kumafutha aqinileyo avuthayo kumaleko wezinto eziphathekayo. Esona sixhaphakileyo sisetyenziswa ngumgubo wecoke ocoliweyo kunye neanthracite, njl njl. Izixhobo ezikrwada zeSintered, ikakhulu zinentsimbi ekrwada, intsimbi yemanganese, isinyibilikisi, isibaso kunye nenkunkuma yamashishini.

Iindidi ezahlukeneyo zeSintering

I-Sintering ibandakanya iindlela ezahlukeneyo zobuchule ezihlelwe ngokusekelwe kwiindlela kunye neemeko ezibandakanyekayo kwinkqubo. Ukuqonda iintlobo ezahlukeneyo ze-sintering kubalulekile ekukhetheni indlela efanelekileyo kwizicelo ezithile. Nazi ezinye iintlobo eziqhelekileyo ze-sintering:

1 I-Solid-State Sintering

I-Solid-state sintering, ekwabizwa ngokuba yi-diffusion bonding, yindlela esetyenziswa ngokubanzi ye-sintering. Kule nkqubo, izinto zomgubo zixhomekeke kumaqondo okushisa aphakamileyo angaphantsi kwamanqaku abo okunyibilika. Njengoko iqondo lokushisa linyuka, ukusabalalisa kwe-athomu kwenzeka phakathi kweengqungquthela ezikufutshane, kuququzelela ukubunjwa kweentamo kunye nokudibanisa. Ukupheliswa kwe-voids kunye nokulungiswa kwakhona kweengqungquthela kukhokelela ekuxineni kunye nokwakhiwa kobunzima obunzima.

I-Solid-state sintering idla ngokusetyenziswa ekuvelisweni kweeseramikhi, ezinje ngeporcelain kunye ne-alumina, kunye nasekutshiseni umgubo wentsimbi. Kunconywa xa kugcinwa ukwakheka kweekhemikhali kunye nokucoceka kwezinto eziphathekayo kubalulekile. Ngokulawula ngononophelo iiparamitha ze-sintering, ezinje ngobushushu, ixesha, kunye noxinzelelo, iipropathi zezinto ezifunwayo zinokufezekiswa.

2 I-Liquid-Phase Sintering

I-Liquid-phase sintering ibandakanya ukongezwa kwesigaba solwelo ukunceda ukuhlenga-hlengiswa kwakhona kwamasuntswana kunye nokudibanisa ngexesha lenkqubo ye-sintering. Isigaba solwelo, esihlala siyinto ephantsi yokunyibilika, sisebenza njenge-binder okanye i-flux, ukunciphisa ubushushu be-sintering obufunekayo ekuxininiseni. Le ndlela isebenziseka ngakumbi xa izinto zokuthambisa ezineendawo eziphezulu zokunyibilika okanye xa kunyuswa izinga loxinaniso olufunwayo.

Ngexesha le-liquid-phase sintering, isigaba se-liquid sisasazeka phakathi kweengqungquthela, ukukhuthaza ukulungiswa kwakhona kwe-particle kunye nokuphucula ukubunjwa kwentamo kunye nokuxinana. Ubukho besigaba se-liquid buye senza ukuba kususwe ukungcola kwaye kuququzelele i-sintering yezinto ezinobumba obuyinkimbinkimbi.

I-Liquid-phase sintering isetyenziswa ngokuqhelekileyo ekuveliseni i-carbides ene-cemented, apho i-tungsten carbide particles idibaniswe kusetyenziswa i-cobalt-based binder. Ikwasetyenziswa ekutshiseni iiseramics ezithile kunye neealloyi zetsimbi, ezifana nentsimbi engatyiwayo.

3 Sintering esebenzayo

I-activated sintering, ekwabizwa ngokuba yi-sintering encediswayo ebaleni okanye i-spark plasma sintering, yindlela yokuqalisa i-sintering esebenzisa imithombo yamandla yangaphandle ukukhuthaza ukuxinana. Ibandakanya ukusetyenziswa kwebala lombane, umsinga wombane, okanye ukusasazeka kwemitha ye-electromagnetic ukuphucula inkqubo yokuntywila.

Umthombo wamandla wangaphandle ukhawuleza ukusasazwa kwe-athomu, okukhokelela ekubunjweni kwentamo ngokukhawuleza kunye nokuxinana. Ukusetyenziswa kwamandla ombane kuvelisa ukufudumeza kwendawo, ukunciphisa ixesha le-sintering kunye nokwenza ukuba i-sintering yezinto eziphathekayo kumaqondo aphantsi. Obu buchule bubonelela ngezinto eziluncedo ezinjengokukhula koxinaniso oluphuculweyo, ukukhula okuncitshisiweyo okuziinkozo, kunye nolawulo olwandisiweyo kulwakhiwo oluncinci kunye neepropati.

I-Sintering esebenzayo ifumana izicelo kwiinkalo ezahlukeneyo, kubandakanywa ukuveliswa kweeseramikhi eziphambili, izinto ezisebenzayo, kunye ne-composites. Iluncedo ngakumbi kwimathiriyeli enamanqaku aphezulu okunyibilika, ukwakheka okuntsokothileyo, okanye ukunyibilika okulinganiselweyo.

4 Ezinye Iintlobo Zokucula

Ngaphandle kwezi ntlobo zikhankanywe ngasentla, kukho ezinye iindlela ezininzi ezikhethekileyo zokucoca ezenzelwe usetyenziso oluthile. Oku kubandakanya ukuntywila kwi-microwave, apho amandla e-microwave asetyenziselwa ukufudumeza kunye nokutshiza imathiriyeli, kunye ne-pressure-assisted sintering, edibanisa uxinzelelo kunye nobushushu ukukhulisa ukuxinana.

Ukongeza, ukukhetha i-laser sintering (SLS) kunye ne-electron beam sintering (EBS) ziindlela zokuvelisa ezongezayo ezisebenzisa imiqadi yamandla ukukhetha izinto ezinomgubo we-sinter, umaleko ngokomaleko, ukuvelisa izinto ezintsonkothileyo ezinamacala amathathu.

Uhlobo ngalunye lwe-sintering lubonelela ngeenzuzo ezizodwa kwaye lukhethwa ngokusekelwe kwiipropati eziphathekayo, iziphumo ezifunwayo, kunye nezicelo ezithile.

Usetyenziso lweSintering

I-Sintering ifumana usetyenziso olubanzi kuwo wonke amashishini ahlukeneyo ngenxa yokukwazi ukuguqula imathiriyeli engumgubo ibe ngamacandelo aqinileyo aneempawu ezongeziweyo. Makhe sihlolisise ezinye zeendawo eziphambili apho i-sintering isetyenziswa ngokubanzi:

1 - iiCeramics

I-Ceramics yenye yeendawo eziphambili apho i-sintering isetyenziswa kakhulu. I-ceramics ye-Sintered ibonisa amandla omatshini aphuculweyo, ukuqina, kunye nokuzinza kwe-thermal. I-Sintering iqeshwe kwimveliso yeethayile ze-ceramic, i-sanitaryware, izixhobo zokusika, izinto eziphikisayo, kunye ne-insulators zombane. Ngokulawula ngononophelo iiparamitha ze-sintering, izinto ze-ceramic zinokufikelela ingxinano efunwayo, i-porosity, kunye ne-microstructure yezicelo ezithile.

2 - Metallurgy

Kwiinkqubo ze-metallurgical, i-sintering isetyenziselwa ukuvelisa uluhlu olubanzi lwamacandelo esinyithi. Oku kubandakanya iigiya, iibheringi, iibhutsi, iinxalenye zeemoto, kunye nezixhobo zesakhiwo. Umgubo wesinyithi, njengentsimbi, i-aluminiyam, kunye nentsimbi engatyiwa, iyadityaniswa kwaye igxininiswe ukuze ivelise iindawo ezomeleleyo ezinomatshini obalaseleyo. Amalungu entsimbi e-Sintered ahlala ebonisa ukomelela okuphezulu, ukuxhathisa ukunxiba, kunye nokuchaneka komda xa kuthelekiswa neendawo eziphothiweyo zemveli.

3 - Iimbumba

I-Sintering idlala indima ebalulekileyo ekuveliseni izinto ezidibeneyo, apho izinto ezimbini okanye ngaphezulu ezihlukeneyo zidityaniswe ukudala izinto ezineempawu eziphuculweyo. Xa kusenziwa imidibaniso yesinyithi yematrix (MMCs) kunye ne-ceramic matrix composites (CMCs), i-sintering isetyenziselwa ukudibanisa imathiriyeli yokuqinisa, njengeentsinga okanye amasuntswana, kunye nemathiriyeli yematrix. Oku kwandisa ukomelela, ukuqina, kunye nokuqina kwesiphumo semathiriyeli edibeneyo.

I-4 - i-Powder Metallurgy

I-Metallurgy yePowder, isebe elikhethekileyo lesinyithi, lixhomekeke kakhulu kwi-sintering. Ibandakanya ukuveliswa kwezixhobo zetsimbi kwi-powder zetsimbi. Ngokusetyenziswa kweenkqubo ezifana nokudityaniswa kunye nokuntywila, iindawo ezintsonkothileyo ezinemilo entsonkothileyo zinokwenziwa. Isinyithi somgubo siqhele ukusetyenziswa kumzi mveliso weemoto ukuvelisa iigiya, iicamshafts, kunye nezihlalo zevalvu, kunye nokwenziwa kwezixhobo zokusika kunye nezihluzi ezisiyiweyo.

5 - 3D Printing / Additive Manufacturing

I-Sintering idlala indima ebalulekileyo kubuchule bokwenza okongeziweyo njenge-selective laser sintering (SLS) kunye ne-electron beam sintering (EBS). Kwezi nkqubo, imathiriyeli engumgubo ikhethwa ngokukhethiweyo umaleko ngokomaleko, ngokusekwe kuyilo lwedijithali, ukwenza izinto ezintsonkothileyo ezinemigangatho emithathu. I-Sintering ivumela ukudibanisa kunye nokudityaniswa kwezinto ezinomgubo, okubangelwa iindawo ezixineneyo kunye nezisebenzayo. Le teknoloji isetyenziswa kumashishini ahlukeneyo, kubandakanya i-aerospace, ukhathalelo lwezempilo kunye neprototyping.

6 Ubunjineli boMbane kunye nobuNjineli boMbane

I-Sintering iqeshwe kwimveliso yezinto zombane kunye nezombane. Kwimveliso yeekeramics ze-elektroniki, ezifana ne-capacitors, i-varistors, kunye ne-thermistors, i-sintering isetyenziselwa ukudibanisa amaqhekeza e-ceramic, ukudala izinto ezixineneyo kunye nezixhobo zombane. I-Sintering iphinda isetyenziswe ekwenziweni koqhagamshelwano lombane, ukupakishwa kwe-semiconductor, kunye namacandelo ebhodi yesekethe.

Le yimizekelo nje embalwa yosetyenziso olwahlukeneyo lokucula. Inkqubo ngokuqhubekayo iphononongwa kwaye icocwe ukuhlangabezana neemfuno eziguqukayo zamashishini ahlukeneyo, okwenza kube lula ukuveliswa kwezinto eziphezulu zokusebenza kunye namacandelo.

Izinto eziluncedo zokuSintering

I-Sintering ibonelela ngeenzuzo ezininzi ezenza ukuba ibe yindlela yokuvelisa ekhethiweyo kumashishini ahlukeneyo. Makhe sihlolisise ezinye zeenzuzo eziphambili:

Iimilo ezi-1 ezintsonkothileyo kunye noYilo oluntsonkothileyo

Enye yeenzuzo ezibalulekileyo ze-sintering kukukwazi ukuvelisa amacandelo anemilo enzima kunye noyilo oluntsonkothileyo. Ngokusebenzisa imathiriyeli ephothiweyo, i-sintering ivumela ukwenziwa kwamalungu anejiyometri entsonkothileyo enokuba ngumceli mngeni ukufikelela kusetyenziswa ubuchule bemveli bomatshini. Oku kuguquguquka ekubunjweni kwenza ukuba kuveliswe amacandelo alungelelanisiweyo ahambelana nezicelo ezithile.

2 Iipropati zoomatshini eziphuculweyo

I-Sintering iphucula iipropathi zoomatshini zezixhobo, okukhokelela kumacandelo aneempawu ezibalaseleyo zokusebenza. Ngethuba lenkqubo ye-sintering, iinqununu zibophe kwaye zixinanise, ezikhokelela ekuphuculeni amandla, ubunzima, kunye nokuxhatshazwa kokugqoka kwemveliso ye-sintered. Iindlela ezilawulwayo zokufudumeza kunye nokusabalalisa okubandakanyekayo kwi-sintering negalelo ekuphuhlisweni kwesakhiwo esixineneyo nesibumbeneyo, ukunyusa ukunyaniseka komatshini wecandelo.

Ukuqulunqwa kwezinto ezi-3 ezilungiselelweyo

I-Sintering ivumela ukudityaniswa kweepowder ezinemixholo eyahlukeneyo, eyenza ukuveliswa kwezinto ezineempawu ezilungiselelwe. Ngokudibanisa iintlobo ezahlukeneyo ze powders okanye ukubandakanya izongezo, kunokwenzeka ukuguqula iimpawu zezinto eziphathekayo ngokweemfuno ezithile. Oku kuguquguquka ekubunjweni kuvula amathuba okudala izinto eziphambili kunye nokusebenza kakuhle, njengama-alloys aphezulu okanye izinto ezinombane okanye izinto ezishisayo.

4 Iindleko-Ngempumelelo

I-Sintering yindlela yokuvelisa indleko esebenzayo xa kuthelekiswa neenkqubo zendabuko zokunyibilika kunye nokuphosa. Ukusetyenziswa kwezinto ezinomgubo kunciphisa inkunkuma yezinto eziphathekayo, njengoko ipowder engaphezulu ingaqokelelwa kwaye isetyenziswe kwakhona. Ukongeza, inkqubo ye-sintering ifuna ukusetyenziswa kwamandla aphantsi kuba isebenza kumaqondo obushushu angaphantsi kwendawo yokunyibilika kwezinto. Ukukwazi ukuvelisa amacandelo e-net-shape kufutshane kunciphisa ngakumbi imfuno yemisebenzi yomatshini elandelayo, okukhokelela ekugcinweni kweendleko ngokubhekiselele kusetyenziso lwezinto eziphathekayo, ukusetyenziswa kwamandla, kunye nokulungiswa emva kokulungiswa.

5 Ukuguquguquka kwezinto ekuKhethweni kwezinto

I-Sintering inikezela ngeendlela ezahlukeneyo ekukhetheni izinto eziphathekayo, ezithatha uluhlu olubanzi lwezixhobo zokusebenza ezahlukeneyo. Ifanelekile kwi-ceramics, isinyithi, kunye ne-composites. Iindidi ezahlukeneyo zemathiriyeli, kubandakanywa i-oxides, i-carbides, i-nitrides, kunye ne-alloys, inokucutshungulwa ngokutshisa. Oku kuhambelana kwezinto ezibanzi kuvumela ukuveliswa kwamacandelo ahlukeneyo kunye neempawu eziphathekayo eziphathekayo, okwenza ukuba i-sintering ibe yinto ekhangayo kumashishini amaninzi.

Izibonelelo ze-Sintering kubume obuntsonkothileyo, iipropathi eziphuculweyo zoomatshini, ukuqulunqwa kwemathiriyeli elungiselelweyo, ukusebenza kakuhle kweendleko, kunye nokuguquguquka kwezinto kuyenza ibe yinkqubo yokwenziwa kwexabiso kumacandelo ahlukeneyo. Ngokusebenzisa ezi zibonelelo, amashishini anokufikelela kwimveliso esebenzayo, ukusebenza okuphuculweyo, kunye nokongiwa kweendleko kwiinkqubo zabo zokuvelisa.

Kukho utshintsho oluninzi olubandakanya utshintsho oluntsonkothileyo lomzimba kunye neekhemikhali. Ukuphendulwa komzimba kunye neekhemikhali kwi-powder sintering kubandakanywa ukujika kwamanzi okanye ukuguquka kwamanzi okanye i-organic matter, ukususwa kweegesi ze-adsorbed, isiqabu soxinzelelo, ukucutha i-oxides engaphezulu kwamasuntswana omgubo, ukufuduka kwezinto, ukuphinda kufakwe ikristale, ukukhula kweenkozo, njl. njl. kunye nokuqonda ulwazi lwe-sintering njengomvelisi. Kwaye njengomthengi, ukufunda olu lwazi lusisiseko kunokusenza sibe nombono olungileyo xa sikhetha iimveliso ze-sintering.

I-Sintering yinkqubo yemveli kunye neyinkimbinkimbi. Amaxesha aya phambili, Kwaye iteknoloji yemveliso kunye nezixhobo zokuvelisa nazo zihlaziywa rhoqo. Gcina ulwazi olusisiseko kwaye ufunde ulwazi olutsha luyimfuneko kubasebenzi abanxulumene noshishino. Kwiminyaka eyi-18 eyadlulayo.HENGKOuhlala egxininisa ekuziphuculeni rhoqo, ukubonelela abathengi ngeemveliso ezilungileyo kunye neenkonzo ezinolwazelelelo, ukunceda abathengi kunye nophuhliso oluqhelekileyo. Sinethemba lokuba iqabane lakho elithembekileyo ixesha elide.

Ii-FAQ (imibuzo ebuzwa rhoqo)

Zeziphi izinto ezinokwenziwa sinter?

Uluhlu olubanzi lwemathiriyeli inokutshizwa, kubandakanywa iiseramics, isinyithi, kunye ne-composites. Imizekelo ibandakanya umgubo weceramic njenge-alumina kunye ne-zirconia, umgubo wentsimbi njengentsimbi kunyeizihluzi zensimbi engenasici, kunye neepowders ezidibeneyo eziqulethe izinto zokuqinisa ezifana neefayibha okanye amaqhekeza.

Zeziphi iingenelo ze-sintering xa kuthelekiswa nezinye iindlela zokwenza?

I-Sintering ibonelela ngeenzuzo ezininzi kwiindlela zokuvelisa zemveli. Ivumela ukuveliswa kwamacandelo anemilo enzima kunye noyilo oluntsonkothileyo, inikezela ngeempawu eziphuculweyo zoomatshini, yenza kube lula ukuqulunqwa kwezinto eziphathekayo, indleko ephantsi ngenxa yokunciphisa inkunkuma yezinto eziphathekayo, kwaye ihlalisa iindidi ezahlukeneyo zezicelo.

Zeziphi izicelo eziphambili ze-sintering?

I-Sintering ifumana usetyenziso kumashishini afana neeseramics, isinyithi, isinyithi somgubo, i-electronics, kunye nokuveliswa okongeziweyo. Isetyenziselwa ukuvelisa iithayile ze-ceramic, iinxalenye zeemoto, izixhobo zetsimbi, izixhobo zokusika, iiseramics ze-elektroniki, kunye nezinto eziprintiweyo ze-3D, phakathi kwabanye.

Ngaba kukho naziphi na izithintelo okanye imiceli mngeni nge-sintering?

I-Sintering inemida kunye nemingeni. Ukufezekisa uxinaniso olufanayo kuyo yonke imathiriyeli kunokuba ngumngeni, njengoko ukufudumeza okungalinganiyo okanye ukuhanjiswa kwamasuntswana kunokubangela iziphene. Ukulawula ukukhula okuziinkozo kunye nokuthintela ukushwabana okugqithisileyo ngexesha le-sintering nazo zibalulekile. Ukongeza, ayizizo zonke izixhobo ezifanelekileyo zokuntywila ngenxa yeendawo ezinyibilikayo eziphezulu okanye ukuphinda kusebenze kunye nomoya ojikelezileyo.

Zeziphi iintlobo ezahlukeneyo zobugcisa sintering?

Kukho iintlobo ngeentlobo zeendlela zobuchule bokuntywila, kuqukwa ne-slid-state sintering, i-liquid-phase sintering, i-activated sintering, i-microwave sintering, i-pressing-assisted sintering, kunye neendlela ezikhethekileyo ezifana ne-selective laser sintering (SLS) kunye ne-electron beam sintering (EBS). Ubuchule ngabunye buneendlela zabo ezizodwa kwaye bukhethwe ngokusekelwe kwiimfuno ezithile zezinto kunye nokusetyenziswa.

I-sintering iphucula njani iimpawu zemathiriyeli?

I-Sintering iphucula iipropati zezixhobo ngokukhuthaza ukudibanisa amasuntswana kunye noxinaniso. Ngethuba lenkqubo ye-sintering, iinqununu zihamba ngokusasazwa, ezikhokelela ekubunjweni kwentamo kunye nokunyuka kobuninzi. Oku kubangela iipropathi eziphuculweyo zoomatshini ezifana namandla, ubulukhuni, kunye nokumelana nokunxiba. Ukongeza, i-sintering inokukhokelela ekuphuculweni kombane, i-thermal, kunye neempawu zeekhemikhali ngokuxhomekeke kwizinto kunye nokwakheka kwayo.

Ngaba iindawo ezifakwe emanzini zingenziwa ngoomatshini okanye ziqhubekeke phambili?

Ewe, iinxalenye ezitshisiweyo zinokuphinda ziqhubekeke okanye zenziwe ngoomatshini, ukuba ziyafuneka. Ngelixa i-sintering inokufikelela kumacandelo akufuphi ne-net-shape, kusenokubakho iimeko apho ukwenziwa kwe-machining ngakumbi okanye ukusetyenzwa kwangemva kuyimfuneko ukufezekisa iinkcukacha ezifunekayo. Iinkqubo zokusila ezifana nokusila, ukugrumba, okanye ukugaya zingasetyenziswa ukuphumeza imilinganiselo yokugqibela okanye ukugqiba umphezulu.

Ziziphi iingqalelo zendalo esingqongileyo ze-sintering?

I-Sintering ngokuqhelekileyo ithathwa njengenkqubo yokwenza izinto ezihambelana nokusingqongileyo. Isebenzisa amandla amancinci xa kuthelekiswa neendlela zokunyibilika kunye nokuphosa, kwaye inciphisa inkunkuma yezinto ngokuvumela ukusetyenziswa kwakhona komgubo ogqithisileyo. Nangona kunjalo, kubalulekile ukuqwalasela impembelelo yokusingqongileyo yemathiriyeli ekrwada esetyenzisiweyo, kunye nokuphathwa ngokufanelekileyo kunye nokulahlwa kwayo nayiphi na imveliso okanye inkunkuma eveliswa ngexesha lenkqubo.

I-Sintering inegalelo njani kuphuhliso lwemathiriyeli ephezulu?

I-Sintering idlala indima ebalulekileyo kuphuhliso lwemathiriyeli ephezulu. Ngokukhetha ngokucophelela kunye nokulawula ukubunjwa, ubungakanani be-particle size, kunye ne-sintering parameters, kunokwenzeka ukuba ulungelelanise iimpawu zezinto ezibangelwayo. Oku kuvumela ukudala izinto eziphambili kunye neempawu ezithile, ezifana ne-alloys ephezulu yokusebenza, i-ceramics esebenzayo, okanye izinto ezidibeneyo ezinokudibanisa okukodwa kweempawu.

Ukuba uneminye imibuzo okanye ungathanda ukuqhagamshelana nayeHENGKO,

Nceda uzive ukhululekile ukuqhagamshelana nathi nge-imeyileka@hengko.com.

Siyakuvuyela ukukunceda kwaye sikunike naluphi na ulwazi olongezelelweyo onokulufuna.

Ixesha lokuposa: Aug-14-2020