I-CEMS Flue Gas Online Monitoring kunye ne-Microporous Sintered Filter

Flue gas esweni steel stainless steel microporous sintered filter element

Flue gas esweni steel stainless steel microporous sintered filter element

Sintered filter element ityhubhu yokucoca igesi ye-cems flue kwi-intanethi kunye nenkqubo yokucoca

I-microporous steel stainless steel powder sintered filter ityhubhu yokuhluza imolekyuli encinci yenziwe ngomgubo wentsimbi engatyiwayo ecinezelwe ngokungundo, ifakwe kubushushu obuphezulu, kwaye yenziwe ngokudibeneyo.Ineengenelo zamandla omatshini aphezulu, ukumelana nobushushu obuphezulu, ukuxhathisa okulungileyo kokubola, ukuhanjiswa kobungakanani bepore efanayo, ukungena komoya okulungileyo, ukuhlaziywa ngokutsha okucocekileyo, kunye nomatshini wokuwelda.Ukulungelelanisa ubungakanani bamasuntswana angumgubo kunye neemeko zenkqubo kwenza kube lula ukuvelisa izakhi zokucoca isinyithi esinezingxobo ezinoluhlu olubanzi lokuchaneka kokucoca.Ngenxa yeenzuzo ezininzi ze-porous metal powder sintered materials, olu hlobo lwemveliso lusetyenziswa ngokubanzi kwi-catalyst recovery, i-gas-liquid Filtration, kunye nokwahlula kwiinkalo zoshishino lwemichiza, amayeza, isiselo, ukutya, isinyithi, i-petroleum, ukhuseleko lokusingqongileyo. ukubilisa;iigesi ezahlukeneyo, Ukususwa kothuli, ukuvala inzala, kunye nokususwa kwenkungu yeoyile yomphunga;ukunciphisa ingxolo, ukubamba amadangatye, isithinteli segesi, njl.

Iimbonakalo:

Iimbonakalo:

1. Imilo ezinzileyo, ukuxhathisa impembelelo, kunye nomthamo womthwalo otshintshanayo ungcono kunezinye izixhobo zokucoca isinyithi;

2. Ukungena komoya, umphumo wokuhlukana okuzinzileyo;

3. Ukulayisha okugqwesileyo kunye namandla othutho, alungele ukusetyenziswa kwiqondo lokushisa eliphezulu, uxinzelelo oluphezulu, kunye neendawo ezomeleleyo ezitshabalalisayo;

4. Ngokukodwa kufanelekile ukuhluzwa kwegesi ephezulu yobushushu;

5. Iimveliso zeemilo ezahlukahlukeneyo kunye nokuchaneka kungenziwa ngokwezifiso ngokuhambelana neemfuno zomsebenzisi, kunye neendawo ezahlukeneyo zokujongana zingasetyenziswa nge-welding.

Ukusebenza: ukuxhathisa kweasidi, ukuxhathisa kwealkali, ukumelana nobushushu obuphezulu, ukumelana nobushushu obuphantsi, uthintelo lomlilo, anti-static

Indawo yokusebenza: i-nitric acid, i-asidi yesulfuric, i-acetic acid, i-oxalic acid, i-asidi ye-phosphoric, i-5% ye-hydrochloric acid, i-sodium etyhidiweyo, i-hydrogen engamanzi, i-nitrogen yolwelo, i-hydrogen sulfide, i-acetylene, umphunga wamanzi, i-hydrogen, igesi, i-carbon dioxide gas, kunye nezinye. iindawo ezingqongileyo.Ineentlobo ngeentlobo ze-porosity (28% -50%), ubukhulu bepore (0.2um-200um), kunye nokuchaneka kwe-filtration (0.2um-100um), kunye nemijelo ye-criss-cross, ukumelana nokushisa okuphezulu, kunye nokupholisa ngokukhawuleza kunye nokumelana nokushisa. .I-anti-corrosion.Ilungele imidiya eyahlukeneyo eyonakalisayo efana neeasidi kunye nealkali.Isihluzo sensimbi engenasici sinokuxhathisa isiseko se-asidi ngokubanzi kunye ne-organic corrosion, efanelekileyo kakhulu ekuhluzeni iigesi ezinesulfure.Inamandla aphezulu kunye nokuqina okulungileyo.Ifanelekile kwiindawo ezinoxinzelelo oluphezulu.Inokudityaniswa.Kulula ukulayisha kunye nokukhulula.Ubume be-pore obuzinzileyo kunye nokusabalalisa okufanayo kuqinisekisa ukusebenza okuzinzileyo kokucoca.Ukusebenza kakuhle kokuhlaziywa.Emva kokucoca ngokuphindaphindiweyo kunye nokuhlaziywa, ukusebenza kokucoca kubuyisela ngaphezu kwe-90%.

Ubushushu bokusebenza: ≤900°C

Ubunzima bodonga: ngokubanzi 3mm

Uxinzelelo lwangaphakathi: 3mpa

Izinto eziphathekayo: 304, 304L, 316, 316L.

Ukwahlulwa kwamasuntswana othuli, ukuhlanjululwa, kunye nokuHlunywa kwentsimbi yentsimbi ecocekileyo enesixhobo sokucoca ineepropati eziluncedo ezifana nokuxhathisa ukubola, ukumelana nobushushu obuphezulu, amandla aphezulu, ukuqinisekiswa lula kokuchaneka kokucoca, kunye nokuvuselelwa lula.I-titanium filter element yenziwe nge-titanium powder emva kokubunjwa kunye nokushisa okuphezulu kwe-sintering, ngoko ke amasuntswana angaphezulu angabi lula ukuwa;ukusetyenziswa emoyeni kunokufikelela kwi-500-600 ° C;ilungele ukucoca imidiya eyahlukeneyo eyonakalisayo, efana ne-hydrochloric acid, i-asidi ye-sulfuric, i-Filtration ye-hydroxide, amanzi olwandle, i-aqua regia kunye nezisombululo ze-chloride ezifana nentsimbi, ubhedu, kunye nesodium.Ineempawu ezigqwesileyo zomatshini, zinomatshini wokusika, i-welding, njl., inamandla oxinzelelo oluphezulu, kwaye ukuchaneka kwayo kokucoca kulula ukuqinisekisa.I-diameter ye-pore ayiyi kuphazamiseka nokuba isebenza phantsi kwamaqondo aphezulu kunye noxinzelelo.I-porosity yayo inokufikelela kwi-35-45%, ukusabalalisa ubungakanani be-pore bufanayo kwaye umthamo wokubamba ukungcola mkhulu, kwaye indlela yokuvuselela ilula kwaye ingaphinda isetyenziswe emva kokuvuselelwa.

Ukwahlulwa kwamasuntswana othuli, ukucocwa, kunye nokuHluzwa kwentsimbi engenasiphene yomgubo we-sintered element inomsebenzi ogqwesileyo.Ingasetyenziswa ngokubanzi kwimimandla yoshishino lwamayeza, ishishini lonyango lwamanzi, ishishini lokutya, ubunjineli bebhayoloji, ishishini lemichiza, ishishini lepetrochemical, ishishini lesinyithi, kunye nokucocwa kwegesi.Yimathiriyeli entsha enethemba lophuhliso olubanzi.

Usetyenziso oluqhelekileyo lubandakanya:

1. Kwishishini lamachiza, lisetyenziselwa ukuhluzwa kwe-decarbonization kwinkqubo yokulungiswa okugxininisiweyo yezisombululo ezinkulu ze-infusion, i-injection encinci, i-eye drops, kunye ne-oral liquids kunye nokuqinisekisa ukhuseleko phambi kwe-terminal Filtration kwinkqubo yokulungiswa kwe-diluted.

2. Ukususwa kokungcola kunye noHlelo kwinkqubo yokuvelisa izinto eziluhlaza, i-decarbonization filtration, kunye nokuFifa okulungileyo kwezinto.

3. Ukucoca okuKhuselekileyo kwi-ultrafiltration, i-RO, kunye neenkqubo ze-EDI kushishino lokucoca amanzi, ukuHlungwa emva kwe-ozone sterilization, kunye ne-ozone aeration.

4. Ukucaciswa kunye noHlelo lweziselo, utywala, ibhiya, ioli yemifuno, amanzi amaminerali, i-soy sauce, kunye neviniga ekutya kunye nesiselo.

5. Ukuhluzwa kwe-decarbonization kunye nokucoca ngokuchanekileyo kweemveliso zolwelo, izinto eziluhlaza, kunye namayeza aphakathi kwishishini lemichiza, ukuhluzwa kunye nokubuyiswa kwamasuntswana e-ultra-fine kunye ne-catalysts, ukuhluzwa okuchanekileyo emva kwe-resin adsorption, kunye nokususwa kokungcola kunye noFiltration ye-oyile yokudlulisa ukushisa kwenkqubo. kunye nezinto, i-catalysis Ukucocwa kwegesi, njl.

6. I-Oilfield ibuyisela ukuhluzwa kwamanzi kunye nebala lokususa ityuwa emanzini olwandle ngaphambi kokuba i-osmosis ibuyele umva ukuqinisekisa ukuhluzwa kokhuseleko.

7. I-decarbonization yobushushu obuphezulu kunye nokucoca ngodongwe olumhlophe kwishishini ledayi.

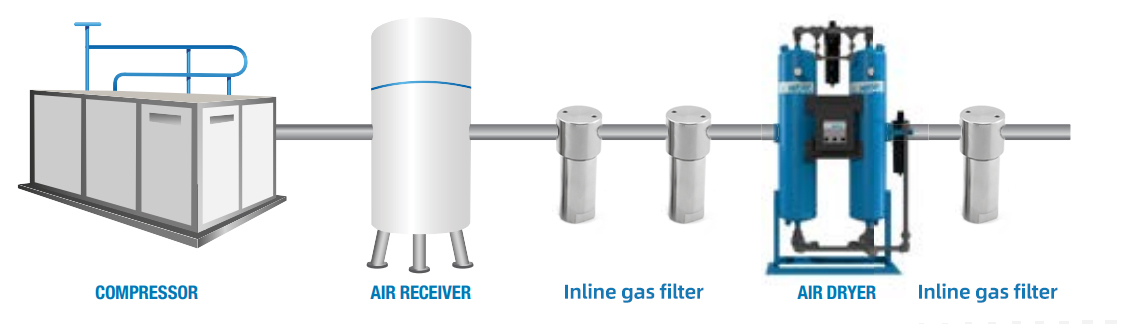

8. Ngokumalunga nokuhlanjululwa kwegesi, kubandakanya ukucocwa kunye nokuHlunywa komphunga, umoya oxinzelelweyo, kunye negesi ye-catalytic.

FAQ

1. Yintoni isihluzo segesi ye-semiconductor yococeko oluphezulu?

Isihluzi segesi ye-semiconductor ecocekileyo luhlobo olukhethekileyo lwesihluzi esenzelwe ukususa ukungcola kwiigesi ezisetyenziselwa ukwenziwa kwezinto zombane.Ezi zihluzo zenziwe kwizinto ezinokumelana nokushisa okuphezulu kunye neekhemikhali ezitshabalalisayo, kwaye zenzelwe ukususa amaqhekeza ukuya kwinqanaba le-nano-scale.

2. Kutheni zibalulekile izihluzi zegesi ze-semiconductor ezicocekileyo?

Kwimveliso ye-semiconductors, kwanamanani amancinci okungcola angabangela iziphene kwaye anciphise umgangatho opheleleyo wemveliso yokugqibela.Izihluzi zegesi ze-semiconductor ezicocekileyo zinceda ekuqinisekiseni ukuba iigesi ezisetyenziswa kwiinkqubo zokuvelisa azikho kungcoliseko, okukhokelela kumgangatho ophezulu wezinto ze-elektroniki.

3. Ziziphi iintlobo zeegesi ezinokuhluzwa ngezihluzo zegesi ze-semiconductor ezicocekileyo?

Izihluzi zegesi ze-semiconductor ezicocekileyo zingasetyenziselwa ukuhluza uluhlu olubanzi lweegesi, kubandakanywa i-hydrogen, i-nitrogen, i-oksijini, kunye neentlobo zezinye iigesi zenkqubo.Ngokuxhomekeke kwinkqubo ethile yokuvelisa, iintlobo ezahlukeneyo zokucoca zingafunwa ukufezekisa inqanaba elifunwayo lokucoceka.

4. Zenziwa njani izihluzi zegesi ezicocekileyo zesemiconductor?

Izihluzi zegesi ze-semiconductor ezicocekileyo zenziwa kwizinto ezifana nensimbi engenasici, kunye nezinye iintsimbi eziphezulu.Izinto zokucoca ziqhelekile ukuba zincinci kakhulu, ezinobungakanani bepore ukusuka kwi-0.1 ukuya kwi-1 micron.Izihluzi zihlala zigqunywe ngezinto ezikhethekileyo zokuphucula iimpawu zazo zomphezulu kunye nokuphucula ukusebenza kwazo.

5. Zihlala ixesha elingakanani izihluzi zegesi ye-semiconductor yococeko oluphezulu?

Ubomi bokucoca igesi ye-semiconductor ephezulu bunokwahluka ngokuxhomekeke kwinani lezinto, kubandakanywa uhlobo lwesihluzo, igesi ehluzwayo, kunye nenkqubo ethile yokuvelisa.Ngokubanzi, ezi zihluzo ziyilelwe ukusetyenziswa ixesha elide kwaye zingahlala iinyanga ezininzi okanye iminyaka ngaphambi kokuba zifune ukutshintshwa.Ukugcinwa rhoqo kunye nokucoca kunokunceda ukwandisa ixesha lokuphila kwezi zihluzo kunye nokuqinisekisa ukusebenza okulungileyo ekuhambeni kwexesha.