-

I-Stainless Steel Sintered Porous Metal Filtered Iityhubhu zesihluzi se-Porosity Ezantsi ukuya kwi-0.2 µm – ku-F...

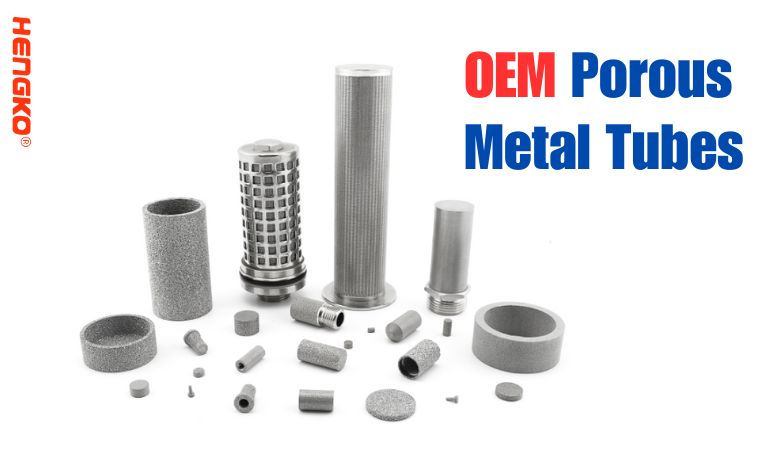

Ubungakanani bePore: 0.2-100microns Izinto: SS Metal Porosity: 30% ~ 45% Uxinzelelo oluSebenzayo: 3MPa Ubushushu bokusebenza: 600℃ Usetyenziso lwesinyithi esinezingxobo ...

Jonga iinkcukacha -

Ukutshintshwa kweNqamza leNqamza leNqamza leNgcaciso yeeNgcebiso zokuGqibela / i-Bioreactor Air Aeration...

Izinto eziluncedo ze-HENGKO Porous Metal Micro Spargers Ngenxa yokunyibilika okuphantsi kweoksijini kwiindawo ezininzi zenkcubeko yeeseli, ukwenza esi sondlo sibaluleke kakhulu kunokuba ...

Jonga iinkcukacha -

IValve yeTire engenaStainless yeTubeless yeTire Eyomeleleyo kwaye eZinzileyo iValve yeTire eZinzileyo Intonga emfutshane yeTruri yeMoto...

Inkcazo yeeMveliso Ivalve sisixhobo somzimba wevalve ezimeleyo evumela irhasi ukuba ingene kwindawo yetayara elingenatyhubhu okanye ityhubhu xa ivulwa, emva koko ...

Jonga iinkcukacha -

Isihluzi seWholeliseli yeWire Mesh yentsimbi engatyiwayo 10 yeMicron Sintered Tube yeM...

Izihluzi zentsimbi engenastainless zilungele ukusetyenziswa kwiinkcukacha zobunjineli ezibango ezifuna ukuhluzwa kwiimeko ezimbi zokusingqongileyo, ezifana nejet en...

Jonga iinkcukacha -

I-Sintered Porous Metal Stainless Steel Filter Tube yeFiber Optic Collimator HENGKO

Imveliso Chaza iikhatriji zetsimbi ezinobukroti zingenziwa ngokwezifiso kwiindidi ezahlukeneyo zezicelo kunye neenkcukacha kwaye zinokuqhotyoshelwa kwisinyithi kunye ne-non-meta...

Jonga iinkcukacha -

Ukuchaneka okuPhezulu kokuSetyenziswa okuPhantsi kwe-I2C yoMsebenzi woBubushushu kunye neSensom ehambelana nokufuma...

Iqondo lobushushu le-HENGKO kunye ne-humidity sensor probe eyenziwe ngenqanaba lokhuseleko le-IP66 lokuqina okuphezulu kokuqina kwentsimbi engenasici, inokusetyenziswa ngokuthe ngqo...

Jonga iinkcukacha -

iqondo lobushushu kunye nesalamane sokufuma kwe-sensor probe kunye netyhubhu yolwandiso lwentsimbi engenastainless kunye ...

I-HT-E067 ehambelana nokufuma / isidluliseli sobushushu sibonelela ngendlela ethembekileyo kunye nexabiso eliphantsi kwizicelo zokubeka iliso kwi-duct mount.Izixhobo zoluvo ezizinzileyo pr...

Jonga iinkcukacha -

Ityhubhu yeSintered Sparger eneTanki yeNtsimbi ePorous Metal kunye neeSparger eziSetyenzisiweyo ezingaphakathi ...

Ukwazisa i-HENGKO ekhethekileyo ye-spagers, esona sisombululo sokwazisa ngeegesi kulwelo.Le mveliso isungulayo isebenzisa amawaka...

Jonga iinkcukacha -

Ukusebenza okuphezulu kwe-porous sintered metal stainless steel isostatic filters iityhubhu ezixhasayo ...

Iityhubhu zetsimbi zetsimbi ezenziwe ngomgubo wentsimbi, zicutshungulwa ngetekhnoloji ye-sintering.Le mveliso inokucoca imidiya engcolileyo kwaye iphumelele ...

Jonga iinkcukacha -

Umatshini wamanzi otyebileyo weHydrogen - i-sintered SS 316L yentsimbi engatyiwa 0.5 2 micron yomoya o...

Amanzi eHydrojeni acocekile, anamandla, kwaye anehydron.Inceda ukuhlambulula igazi kwaye ihambisa igazi.Inokuthintela iintlobo ezininzi zezifo kwaye iphucule abantu...

Jonga iinkcukacha -

iFakelwe Ngqo Ngqo Metal Metal In-Line Sparger Tube Yenza amaqamza amancinci

I-HENGKO sintered spagers yazisa iigesi kulwelo ngamawaka eepores ezincinci, zenza amaqamza amancinci kwaye maninzi ngakumbi kunombhobho owombiweyo ...

Jonga iinkcukacha -

I-316L yentsimbi engenazinkcenkce yentsimbi echanekileyo yokucoca iityhubhu enemilo ye-sparging

I-Sintered air stone diffusers ihlala isetyenziselwa ukutofa irhasi eneporous.Zinobukhulu obahlukeneyo bepore (0.5um ukuya kwi-100um) evumela amaqamza amancinci ukuba ahambe phakathi kwe ...

Jonga iinkcukacha -

I-316L yensimbi engenasici ye-porous sparger ityhubhu ene-sintered incam yezixhobo zokubilisa inqanawa

Incamathela kwincam yetyhubhu yesparger, le 316L yentsimbi engenasici sintered tip ifumaneka kwiintlobo ngeentlobo zeepore.I-5 10 15 50 100 i-pore frit yi ...

Jonga iinkcukacha -

Cylindrical 25 50 micron intsimbi yensimbi engaxutywanga microns porous powder sintered filter tyhubhu for...

I-HENGKO i-stainless steel filter iityhubhu zenziwe nge-sintering 316L yomgubo wezinto okanye i-multilayer ye-wire mesh yensimbi engenasici kumaqondo obushushu aphezulu.Bakhe ba...

Jonga iinkcukacha -

Ityhubhu enombhobho yokucoca isinyithi yokucoca ulawulo lwe-thermal kunye neekhemikhali ezikhethekileyo |HENGKO

I-HENGKO i-stainless steel filter iityhubhu zenziwe nge-sintering 316L yomgubo wezinto okanye i-multilayer ye-wire mesh yensimbi engenasici kumaqondo obushushu aphezulu.Bakhe ba...

Jonga iinkcukacha -

Umvelisi oqeqeshiweyo olungelelanisiweyo ityhubhu yesihluzo sesinyithi esinebhobhobhosi esisetyenziselwa unyango...

Izihluzi ze-HENGKO sintered zihlala zisetyenziselwa ukucocwa kunye nokuhluzwa kolwelo kunye negesi, ukwahlukana kunye nokubuyiselwa kwamasuntswana aqinileyo, ukupholisa umoya...

Jonga iinkcukacha -

I-0.2um ukuya kuma-90 micron 5 – 100mm ukuphakama ngumgubo okanye umnatha wocingo olunezingxobo zentsimbi...

I-HENGKO i-stainless steel filter iityhubhu zenziwe nge-sintering 316L yomgubo wezinto okanye i-multilayer ye-wire mesh yensimbi engenasici kumaqondo obushushu aphezulu.Bakhe ba...

Jonga iinkcukacha -

Sintered metal powder porous 316l SS steel stainless filter ityhubhu, 2 μm 5 7 10 15 20 30 ...

I-HENGKO i-stainless steel filter iityhubhu zenziwe nge-sintering 316L yomgubo wezinto okanye i-multilayer ye-wire mesh yensimbi engenasici kumaqondo obushushu aphezulu.Bakhe ba...

Jonga iinkcukacha -

2 10 20 25 microns porous SS 304/316L metal sintered steel stainless filter ityhubhu for li...

I-HENGKO i-stainless steel filter iityhubhu zenziwe nge-sintering 316L yomgubo wezinto okanye i-multilayer ye-wire mesh yensimbi engenasici kumaqondo obushushu aphezulu.Bakhe ba...

Jonga iinkcukacha -

Sintered metal 316 steel stainless steel filter yonyango ityhubhu yokucoca ulwelo kunye negesi ...

Imveliso Chaza imathiriyeli yokuhluza i-Porous isetyenziswe ngokubanzi kwi-metallurgical, ikhemikhali, amayeza, i-aerospace, kunye nemimandla ye-aviation.Porous Metal media...

Jonga iinkcukacha

Kutheni Usebenzisa Ityhubhu yeMetal enePorous?

Kukho izizathu ezininzi eziphambili zokuba kutheni iityhubhu zetsimbi ezinqabileyo zisetyenziswa kwizicelo ezahlukeneyo:

Uhluzo:

* Umsebenzi wabo ophambili kukuhluza.Ubungakanani bepore obulawulwa ngokuchanekileyo bubavumela ukuba basuse ukungcola, amasuntswana, kunye nongcoliseko olusuka kulwelo kunye neegesi.Oku kunokubaluleka kumashishini afana namayeza, ukusetyenzwa kweekhemikhali, kunye nokutya nesiselo, apho ucoceko luyimfuneko.

* Ubungakanani bePore bunokususela kwi-submicron ukuya kwiimilimitha ezininzi, okubenza bakwazi ukuhluza uluhlu olubanzi lobungakanani bamasuntswana.

Ukuhamba okulawulwayo:

• Ulwakhiwo olunemingxuma luvumela ukuhamba okulawulwayo kolwelo kunye neegesi.

Oku kungasetyenziselwa i-aeration, ukuhanjiswa kwegesi, i-fluidization, kunye nezinye izicelo apho ulawulo oluchanekileyo lokuhamba luyimfuneko.

* Ukuhanjiswa kwepore efanayo kuqinisekisa ukuhamba okuhambelanayo kuyo yonke ityhubhu, ukuthintela umjelo kunye nokusabalalisa uxinzelelo olungalinganiyo.

Ukuqina kunye nokomelela:

• Yenziwe ngeentsimbi ezifana nentsimbi engatyiwa, i-nickel, okanye ubhedu, iityhubhu zetsimbi ezinabileyo zomelele kwaye ziyakwazi ukumelana neemeko zokusebenza ezinzima, kuquka amaqondo obushushu aphezulu, uxinzelelo, kunye nemekobume enomhlwa.

* Oku kubenza bafanelekele ukusetyenziswa ixesha elide kwizicelo ezifunwayo zemizi-mveliso.

Olunye uncedo:

• Iityhubhu zentsimbi ezinentunja nazo zikhaphukhaphu, zicocwa lula, kwaye zinokuphinda zisetyenziswe.Zinokwenziwa ngokulula ngoomatshini zize zibunjwe zibe ziintlobo ezahlukahlukeneyo, zandise ngakumbi ukuguquguquka kwazo.

Nantsi eminye imizekelo ethile yezicelo apho kusetyenziswa iityhubhu zetsimbi ezinentunja:

*Izahlulo zomoya:kwizityalo zokucoca amanzi amdaka ukwazisa ioksijini emanzini ukuze kukhule ibhaktiriya.

* Izihluzi zamafutha:ezimotweni nakwezinye iimoto ukususa ubumdaka kwipetroli.

* Ufakelo lwezonyango:ukwenzela ukungena kwamathambo kunye nokuhanjiswa kweziyobisi.

* I-Catalyst ixhasa:kwii-reactors zekhemikhali ukubamba kunye nokusabalalisa ii-catalysts.

* Izithulisi:kwiinkqubo zokukhupha ukunciphisa ingxolo.

Ekugqibeleni, izizathu ezicacileyo zokuba kutheni umntu enokukhetha ityhubhu yensimbi ene-porous ixhomekeke kwisicelo esithile kunye neemfuno zayo.Nangona kunjalo, indibaniselwano yabo ekhethekileyo yokuhluza, ukuhamba okulawulwayo, ukuqina, kunye nezinye izibonelelo zibenza babe sisixhobo esibalulekileyo kuluhlu olubanzi lwamashishini.

Umsebenzi ongundoqo

Iityhubhu yensimbi ene-sinterediphantse yasebenza ngokufanayo nezinyeizihluzi zetsimbi zentsimbi or sintered metal sparger.

Umsebenzi oyintloko weetyhubhu zetsimbi ezinqabileyo kukubonelela ngokucokisekileyo kunye nokuthembekileyo, ukuhlukana kunye nokulawula

ukuhamba kwamanzi kunye negesi.

Ezi tyhubhu zentsimbi zenziwe ngexabiso le-316L SS amasuntswana entsimbi adityaniswe kunye ngokuntywila.

inkqubo, ukudala isakhiwo esinemingxuma edibeneyo.Iimpawu ezikhethekileyo zeetyhubhu zetsimbi ezinobuncwane

zivumela ukuba zisebenze imisebenzi emininzi ebalulekileyo:

1. Uhluzo:

Eyona njongo iphambili yeetyhubhu zetsimbi ezirhabaxa kukusebenza njengezihluzi, ukususa ukungcola, amasuntswana, kunye neengcoliseko ezisuka kulwelo kunye neegesi.Ulawulo oluchanekileyo lobungakanani be-pore lubavumela ukuba bafezekise ukuhluzwa kakuhle ukuya kumanqanaba e-submicron, ukuqinisekisa ukucoceka kwendawo eqhutyelwayo.

2. Ukusasazwa kweGesi kunye nolwelwe:

Iityhubhu zetsimbi ezinamaqhekezazisetyenziselwa ukusasaza iigesi okanye ulwelo ngokulinganayo nangokulinganayo.Ngokulawula ubungakanani bepore kunye nokusabalalisa, banokwenza ipateni efanayo yokuhamba, ukukhusela umjelo kunye nokuphucula ukusebenza kakuhle kokusasazwa.

3. Ulwelo:

Kwiinkqubo zebhedi ezimanzi, ezi zityhubhu zisetyenziselwa ukukhupha amasuntswana aqinileyo, okwenza imeko efana ne-fluid emisiwe.Ukusasazwa okufanayo kwee-pores kunceda ekufezekiseni i-fluidization esebenzayo kunye nokulawulwayo.

4. Ukukhupha umoya kunye nokuLinganisa koxinzelelo:

Iityhubhu zentsimbi ezinabileyo zisetyenziselwa ukukhupha iigesi, ukulinganisa uxinzelelo, okanye ukuthomalalisa iimeko zevacuum kwiinkqubo ezahlukeneyo kunye nezixhobo.Benza ukudlula komoya okanye igesi ngelixa bethintela ukungena kwezinto ezingcolileyo.

5. Ukunciphisa ingxolo:

Kwezinye izicelo, iityhubhu zentsimbi ezinabileyo zisetyenziswa njengezithulisi okanye iimufflers ukunciphisa amanqanaba engxolo aveliswa kukuhamba kweegesi okanye ulwelo.

6. Ukusasazwa:

Iityhubhu zesinyithi ezinamazinyo ziququzelela inkqubo yokusasazwa kwerhasi okanye ulwelo ngokuvumela iimolekyuli ukuba zidlule kwimibhobho yazo edityanisiweyo.Le propati ifumana isicelo kwiinkalo ezahlukeneyo, ezifana ne-catalysis kunye nemisebenzi yokudlulisa ubunzima.

7. Inkxaso kunye noKwabiwa:

Kumashishini athile, iityhubhu zetsimbi ezinobuncwane zisebenza njengezakhiwo zokuxhasa i-catalysts okanye ezinye izinto, ukubonelela ngesakhelo esizinzileyo kunye nokunceda ukusabalalisa okufanayo.

Ngenxa ye-porosity ephezulu, ukuqina, ukuxhathisa kweekhemikhali, kunye nezakhiwo ze-pore ezilawulwayo, iityhubhu zetsimbi ezinamanzi zifumana ukusetyenziswa kakhulu kumashishini afana namayeza, i-petrochemicals, unyango lwamanzi, i-automotive, i-aerospace, kunye nezinye ezininzi, apho ukuhluza okusebenzayo kunye neenkqubo ezilawulwayo zokuhamba kubalulekile. ukusebenza ngokugqibeleleyo kunye nokhuseleko.

Umgaqo wokuSebenza weSintered Porous Metal Tubes

Umgaqo-nkqubo wokusebenza kweetyhubhu zetsimbi ezine-sintered zisekelwe kwiimpawu ezizodwa zesakhiwo sesinyithi esine-sintered, esivumela ukuhluzwa okusebenzayo kunye nokulawulwa kokuhamba kwamanzi kunye neegesi.Nantsi isishwankathelo somgaqo wokusebenza:

1. Inkqubo yeSintering:

Iityhubhu zentsimbi ezinabileyo zenziwe ngenkqubo ebizwa ngokuba yi-sintering.Kubandakanya ukuhlanganisela amasuntswana esinyithi, ngokuqhelekileyo intsimbi engenasici okanye ezinye ialloys zetsimbi, zibe kwimilo ethile, njengetyhubhu.Amasuntswana esinyithi afudunyezwa kwiqondo lobushushu elingaphantsi nje kweqondo lokunyibilika kwawo, nto leyo ebangela ukuba adibane, enze uthungelwano oluqinileyo noludityanisiweyo lwe pores.

2. Ulwakhiwo lwePore:

Iityhubhu zetsimbi ezine-sintered zinesakhiwo esichaziweyo se-pore ngenxa yokucwangciswa kweengqungquthela zetsimbi ngexesha lenkqubo ye-sintering.Ubungakanani, imilo, kunye nokuhanjiswa kwezi pores kunokulawulwa ngokuchanekileyo ngexesha lokwenziwa kwemveliso ukuhlangabezana neemfuno ezithile zokuhluza.

3. Uhluzo:

Owona msebenzi uphambili weetyhubhu zetsimbi ezinentunjana ezinamanzi kukuhluza.Xa i-fluid okanye igesi idlula kwi-tube, ukungcola, amaqhekeza, kunye nokungcola kufakwe ngaphakathi kweepores.Ubungakanani bepore yenzelwe ukuvumela ulwelo olufunwayo okanye irhasi ukuba idlule ngelixa uvimba izinto ezingafunwayo.

4. Ukusebenza kakuhle koHlulo:

Ukuhluza okusebenzayo kweetyhubhu zetsimbi ezine-sintered zixhomekeke kubukhulu bepore kunye nommandla opheleleyo okhoyo wokucoca.Iisayizi ezincinci zepore zinokuthi zibambe amasuntswana acolekileyo, zibonelela ngokusebenza kakuhle kokucoca.

5. Ulawulo lokuqukuqela:

Isakhiwo esidibeneyo se-pore yeetyhubhu zetsimbi zetsimbi zenza ulawulo oluchanekileyo phezu kokuhamba kwamanzi okanye igesi.Ubungakanani kunye nokusabalalisa kwee-pores kuchaphazela izinga lokuhamba kunye nokuhla kwengcinezelo kwi-tube.Le propati ibalulekile kwizicelo apho ukuhanjiswa okuhamba ngokufanayo okanye ukuhanjiswa okulawulwayo kufuneka.

6. Ukuqina kunye noKuxhathisa:

Iityhubhu zetsimbi ezisiyiweyo zihlala ziqinile kwaye zixhathisa kuxinzelelo lomatshini, iikhemikhali, kunye nobushushu obuphezulu.Inkqubo ye-sintering iqinisekisa ukuba iinqununu zetsimbi ziboshwe ngokuqinileyo, zibonelela ngokunyaniseka kwesakhiwo naphantsi kweemeko zokusebenza ezinzima.

7. Ukusebenziseka kwakhona kunye nokucoceka:

Iityhubhu zetsimbi ezinabileyo ziyakwazi ukucocwa lula kwaye ziphinde zisetyenziswe.Banokumelana neendlela ezahlukeneyo zokucoca, ezifana nokuhlamba umva, ukucocwa kwe-ultrasonic, okanye ukucocwa kweekhemikhali, ngaphandle kokuphazamisa ukusebenza kwabo kakuhle kokucoca.

Umgaqo-nkqubo wokusebenza kweetyhubhu zetsimbi ezine-sintered zizenza ziguquguquke kakhulu kwaye zilungele uluhlu olubanzi lwezicelo kumashishini afana neepetrochemicals, amayeza, unyango lwamanzi, i-aerospace, kunye nokunye.Bakhethwa ngenxa yokucoca ngokufanelekileyo, ukuqina, kunye nokukwazi ukumelana neendawo ezinzima, ukubonelela ngokusebenza okuthembekileyo kwiinkqubo ezibalulekileyo kunye neenkqubo.

Yintoni omawuyikhathalele xa iiThubhu zeMetal eziKhethekileyo ze-OEM kwiiprojekthi zakho zokuhluza?

Xa uqwalasela iityhubhu zentsimbi ezikhethekileyo ze-OEM zenkqubo yakho yokuhluza okanye iiprojekthi, kukho izinto ezininzi ezibalulekileyo ekufuneka uzithathele ingqalelo ukuze uqinisekise ukusebenza kakuhle kunye nokuphunyezwa ngempumelelo.Nantsi eminye imiba ephambili:

1. IiMfuno zoHluzo:

Cacisa ngokucacileyo iimfuno ezithile zokucoca kwisicelo sakho.Qinisekisa ukusebenza kakuhle kokucoca okufunekayo, ubungakanani bepore, kunye nesantya sokuhamba esifunekayo ukufezekisa iziphumo ezifunwayo.

2. Iimpawu zolwelo okanye zerhasi:

Qonda iimpawu zolwelo okanye irhasi eza kuhluzwa, kubandakanywa ubushushu, uxinzelelo, i-viscosity, kunye nokuhambelana kweekhemikhali.Qinisekisa ukuba izinto ezikhethiweyo zetsimbi ze-porous ziyakwazi ukumelana neemeko zokusebenza ezijoliswe kuzo.

3. Ubungakanani bePore kunye noLwakhiwo:

Sebenza nomvelisi we-OEM ukwenza ubungakanani bepore kunye nolwakhiwo lweetyhubhu zentsimbi ezirhabaxa ukuze zihambelane neemfuno zesicelo sakho.Qwalasela ubungakanani bamasuntswana ongcoliseko oluza kususwa kunye neempawu zokuqukuqela ezifunwayo.

4. Ukukhethwa kwezinto:

Khetha impahla yentsimbi efanelekileyo ngokusekelwe kwimichiza yayo yokuxhathisa, iimpawu zomatshini, kunye nokuhambelana nokuhluzwa okuphakathi.Izinto eziqhelekileyo zibandakanya insimbi engenasici, ubhedu, i-nickel, kunye ne-titanium.

5. Uyilo kunye neJometri:

Sebenzisana nomvelisi we-OEM ukuyila imilo yetyhubhu kunye nemilinganiselo ukuze ilingane nenkqubo okanye iprojekthi yakho.Qwalasela izinto ezifana nobude, idiameter, kunye nesiphelo soqhagamshelo ukwenzela ukudibanisa lula.

6. Ukusebenza kakuhle koHlulo kunye nokuLahla koxinzelelo:

Lungelelanisa ukusebenza kakuhle kokuhluza kunye nokuhla koxinzelelo kwiityhubhu zentsimbi ezirhabaxa.Ukusebenza kokucoca okuphezulu kunokukhokelela ekwehleni koxinzelelo, okunokuchaphazela ukusebenza kwenkqubo.

7. Ukucoceka kunye noLondolozo:

Xoxa ngokucoceka kunye neemfuno zokugcinwa kweetyhubhu zetsimbi ezinabileyo.Qinisekisa ukuba zinokucocwa ngokulula kwaye ziphinde zisetyenziswe ukwandisa ubomi kunye nokunciphisa ixesha lokuphumla.

8. Ukwenza ngokwezifiso kunye nobuNgcali:

Sebenza kunye nomvelisi onamava we-OEM kunye nerekhodi eqinisekisiweyo ekuveliseni iityhubhu ezikhethekileyo zentsimbi.Bamele babe nobuchule bokwenza iibhubhu ngokwezifiso ngokweemfuno zakho ezizodwa.

Ngokuqwalasela ngenyameko le miba kunye nokusebenzisana ngokusondeleyo nomvelisi we-OEM, unokuqinisekisa ukuba i-OEM iityhubhu zentsimbi ezinqabileyo ezikhethekileyo ziyilwe kwaye zilungelelaniswe ukuhlangabezana nenkqubo yakho yokuhluza okanye iimfuno ezizodwa zeprojekthi, ekugqibeleni zikhokelela ekuphuculeni ukusebenza kakuhle, ukuthembeka, kunye nokusebenza.

FAQ

1. Ziziphi iimpawu eziphambili zeetyhubhu zetsimbi ezine-porous sintered?

Iityhubhu zentsimbi ezinarhaxayo zibonelela ngeempawu ezininzi eziphambili ezizenza zibe zizodwa kwaye zibe luncedo kakhulu kwizicelo ezahlukeneyo.Ezi mpawu ziquka:

- UkuSebenza okuPhakamileyo koHlelo: Ukulawulwa ngokuchanekileyo kobungakanani bepore kuvumela ukuhluzwa okusebenzayo ukuya kumanqanaba e-submicron, ukuqinisekisa ukukhutshwa kwezinto ezingcolileyo kunye nokungcola kumanzi kunye neegesi.

- Ukuqina kunye namandla: Inkqubo ye-Sintering ibhondi iincinci zetsimbi, inika amandla omatshini kunye nokuchasana nokuguqulwa, naphantsi kweemeko ezinzima.

- Iqondo elibanzi lobushushu kunye noxinzelelo loxinzelelo: Iityhubhu zinokusebenza kwiindawo ezigqithisileyo, zigcina ingqibelelo yesakhiwo kunye nokusebenza kakuhle kokucoca kuluhlu olubanzi lwamaqondo obushushu kunye noxinzelelo.

- Ukuhambelana kweMichiza: I-inert yekhemikhali kwaye iyamelana nokuhlwa, izenza zilungele ukuhluza iikhemikhali ezinobundlobongela kunye nemithombo yeendaba ezonakalisayo.

- Ukucoceka kunye nokuSetyenziswa kwakhona: Iityhubhu zentsimbi ezinebhobhobhobho zicoca ngokulula kwaye ziphinde zisetyenziswe amaxesha amaninzi, ukunciphisa iindleko zokulondolozwa kunye nokwandisa ubomi besihluzi.

2. Zisebenza njani iityhubhu zentsimbi ezinabileyo njengezihluzi?

Ukusebenza kweetyhubhu zetsimbi ezinabileyo njengezihluzi zisekwe kulwakhiwo oludityanisiweyo lwepore.Xa i-fluid okanye igesi igeleza kwi-tube, ukungcola kunye neengqungquthela zifakwe ngaphakathi kwee-pores ngelixa zivumela i-medium efunwayo ukuba idlule.Ubungakanani, ukuhanjiswa, kunye nokucwangciswa kwee-pores kumisela ukusebenza kakuhle kokucoca kunye nohlobo lwamasuntswana anokususwa.Intsimbi ene-sintered ye-porosity ephezulu kunye neepores ezintle zivumela ukuhluzwa okusebenzayo, okwenza ezi ityhubhu zilungele izicelo ezibalulekileyo apho kufuneka ukuhluzwa okuchanekileyo nokuthembekileyo.

3. Ziziphi izinto eziqwalaselwayo ngokufakela iityhubhu zetsimbi ezine-porous sintered kwinkqubo?

Ufakelo olululo lubalulekile ukuqinisekisa ukusebenza ngokukuko kweetyhubhu zetsimbi ezinabileyo.Ezinye izinto eziqwalaselwayo ziquka:

- Ukutywinwa okufanelekileyo: Qinisekisa uqhagamshelo olukhuselekileyo kunye nokuvuza okungavuziyo kuzo zombini iziphelo zetyhubhu ukuthintela ukudlula kunye nokugcina ukusebenza kakuhle kokucoca.

- Ukuqhelaniswa: Misa ityhubhu ngokuchanekileyo ukuqinisekisa ukuba ulwalathiso lokuhamba luhambelana nomsebenzi owenziweyo, nokuba kukucoca, ukukhupha umoya, okanye ukukhupha amanzi.

- Inkxaso kunye nokuKhuselwa: Ukubonelela ngenkxaso eyaneleyo kunye nokukhuselwa ukukhusela umonakalo kwiibhubhu ngexesha lofakelo kunye nokusebenza.

4. Zeziphi izicelo ezinokuthi zisetyenziswe iityhubhu zetsimbi ezinamanzi?

Iityhubhu zetsimbi ezinamanzi zifumana izicelo kuwo wonke amashishini ahlukeneyo, kubandakanya:

- Iikhemikhali zePetroli kunye nokusulungekiswa:Ukufumana inkxaso ye-catalyst, ukuhluzwa kolwelo lwenkqubo, kunye nezicelo zokusasazwa kwegesi.

- Amachiza:Kwindawo yokungena umoya ongenanto, ukuhluzwa kwerhasi, kunye neenkqubo zokuhanjiswa kweziyobisi.

- Unyango lwamanzi:Ukucocwa kwamanzi amdaka, ukuphefumla, kunye nokuhluzwa kwamanzi okusela.

- I-Aerospace:Kwiinkqubo zamafutha kunye ne-hydraulic yokuhluza kunye nokukhupha umoya.

- Iimoto:Kulawulo lokukhutshwa, ukuhluzwa kwamafutha, kunye neenkqubo zokuthambisa.

- Ukutya kunye nesiselo:Ukwenzela isiselo se-carbonation, i-aeration, kunye nokuhluzwa komphunga.

5. Iityhubhu zetsimbi ezinabombhobho zinegalelo njani ekusebenzeni kakuhle kwenkqubo kunye nokusebenza?

Iityhubhu zetsimbi ezinebhobhobhobho ziphucula ukusebenza kakuhle kwenkqubo kunye nokusebenza ngoku:

- Ukuqinisekisa ukusebenza kakuhle kokucoca, okukhokelela ekucoceni kunye nolwelo olucocwe ngakumbi okanye iigesi.

- Ukubonelela ngokusasazwa kokuhamba okufanayo, ukuthintela umjelo okanye ukuhanjiswa koxinzelelo olungalinganiyo.

- Ukumelana neemeko ezinzima, ukunciphisa ixesha lokuphumla kunye neendleko zokugcina.

- Ukuququzelela ukusasazwa kwegesi kunye neenkqubo zokukhupha amanzi, ukuphucula ukuphendula kweekhemikhali kunye nemisebenzi yokudlulisa ubunzima.

6. Ngawaphi amanyathelo okulawula umgangatho asetyenziswayo ngexesha lokwenziwa kweetyhubhu zetsimbi ene-porous sintered?

I-HENGKO njenge-Top Sintered Metal Filter abavelisi baphumeza amanyathelo angqongqo olawulo lomgangatho kuyo yonke inkqubo yokuvelisa.Oku kuquka:

- Umgangatho weMpahla: Ukusebenzisa iincinci zetsimbi eziphezulu zokuqinisekisa amandla omatshini kunye nokumelana neekhemikhali.

- Ulawulo lobungakanani bePore: Ulawulo oluchanekileyo lweeparamitha ze-sintering ukufezekisa ubungakanani obufunwayo bepore kunye nokusabalalisa.

- Ukuchaneka koMda: Ukuqinisekisa ukunyamezelana okuqinileyo ukuhlangabezana neenkcukacha zabathengi.

- Uvavanyo lokuSebenza: Ukuqhuba iimvavanyo zobuchule bokuhluza, uvavanyo lokwehla koxinzelelo, kunye novavanyo lwamandla oomatshini.

Ukufumana izisombululo ezenzelwe wena kunye nezisebenzayo zeOEM Porous Metal Tubes, qhagamshelana noHENGKO namhlanjeka@hengko.com.

Iqela lethu leengcali likulungele ukukunceda ekwenzeni isisombululo esifanelekileyo sokuhluza kwiimfuno zakho ezithile.Nokuba

yeyokuhluza, ukusasazwa kwerhasi, ulwelo, okanye nasiphi na esinye isicelo, sinamava kunye nobuchule bokuzisa

iityhubhu zentsimbi ezikumgangatho ophezulu ezihlangabezana neemfuno zakho.

Ungalibazisi ukufikelela kuthi ukuze ufumane iingcebiso kunyemasikuncede wenze ngcono inkqubo yakho yokucoca okanye iprojekthi.

Sithumelele i-imeyileka@hengko.comngoku kwaye uthathe inyathelo lokuqalangokubhekiselele kwimpumelelo eyongeziweyo kunye nokusebenza nge

Umgangatho weHENGKOItyhubhu yentsimbi ene-sintered.