Izihluzi ze-Sintered ziyinxalenye ebalulekileyo kwiinkqubo ezininzi zemizi-mveliso.

Ngokwenyani zizihluzi zentsimbi ezenziwe ngokudibanisa amasuntswana esinyithi kunye, ngenkqubo ebizwa ngokuba yi-sintering,

kumaqondo obushushu angaphantsi kwendawo yokunyibilika. Olu lwakhiwo lukhethekileyo lubanika iingenelo ezininzi:

* I-porosity ephezulu:

Ziqulethe ipesenti enkulu yendawo engenanto, evumela ulwelo ukuba ludlule ngelixa ubamba amaqhekeza angafunekiyo.

* Ukomelela kunye nokuqina:

Izihluzi ze-Sintered zomelele kwaye ziyakwazi ukumelana noxinzelelo oluphezulu kunye namaqondo obushushu.

* Ukuguquguquka:

Zingenziwa ngeentsimbi ezahlukeneyo kwaye ziza ngobukhulu bepore ezahlukeneyo ukuze zihambelane noluhlu olubanzi lweemfuno zokuhluza.

Ezi mpawu zenza ukuba izihluzi ze-sintered zibaluleke kwizicelo ezahlukeneyo zamashishini. Zisetyenziswa kakhulu kwi:

* Ukulungiswa kweekhemikhali:

Ukucoca ii-catalysts, ukwahlula iimveliso ezinqwenelekayo kwimixube yokusabela, kunye nokususa ungcoliseko.

* Ukutya kunye nesiselo:

Ukucacisa ulwelo, ukususa ibhaktheriya, kunye nokucoca amasuntswana angafunekiyo.

* Amachiza:

Izisombululo zokucoca, ukuhluza ukungcola, kunye nokulawula ubungakanani bamasuntswana kumayeza.

* Iimoto:

Ukuhluza izibaso, izithambiso, kunye nolwelo olwenziwa ngamanzi.

* Ukuhluzwa komoya kunye negesi:

Ukususa uthuli, amasuntswana, kunye nezingcolisi emoyeni nakwimijelo yerhasi.

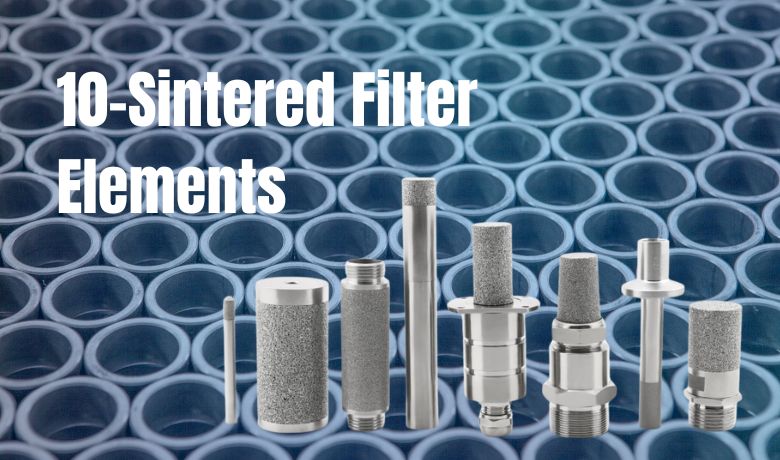

Emva koko njengokulandelayo, ndizakuqala ukunazisa izinto ezili-10 zohluzo lwe-sintered ezithandwayo ezisetyenziswa kwintengiso.

1. Izihluzi zeNtsimbi yeSintered Engatyiwayo

Izihluzi zensimbi engenastainless luhlobo oluguquguqukayo noluthembekileyo lwemithombo yokucoca esetyenziswa kakhulu kwirhasi yeshishini.

kunye nezicelo zokucoca ulwelo. Ziveliswa ngokudibanisa amasuntswana entsimbi estainless kunye nge-sintering

inkqubo kwiqondo lokushisa eliphezulu, ngaphantsi kwendawo yokunyibilika kwentsimbi. Le nkqubo ye-sintering idala isinyithi esiqinileyo, esinemingxuma

Ulwakhiwo olunikezela ngeempawu ezininzi eziphambili:

* Amandla aphezulu kunye nokuqina:

Izihluzi zensimbi ezingenasici zinokumelana noxinzelelo oluphezulu kunye namaqondo obushushu, zizenze zilungele imeko yeshishini elifunayo.

* Ukumelana nokugqwesa okugqwesileyo:

Insimbi engagqwali ngokwendalo iyamelana nokubola ukusuka kuluhlu olubanzi lweekhemikhali, izenza zilungele ukusetyenziswa kunye nolwelo olurhabaxa.

* I-porosity ephezulu:

Izihluzi ze-Sintered zinepesenti enkulu yendawo engenanto ngaphakathi kwesakhiwo sazo, ezivumela ukuhamba okuphezulu kolwelo kunye neegesi.

ngelixa ubambe ngokufanelekileyo amasuntswana amakhulu kunobungakanani bepore.

* Ukuguquguquka:

Zingenziwa ngokweemilo kunye nobukhulu obahlukeneyo kunye noluhlu olubanzi lweereyithingi ze-micron ukuze zihambelane noluhlu oluhlukeneyo lweemfuno zokuhluza.

* Ukucoca ngokulula:

Izihluzi zensimbi ezingenasici zinokuhlanjwa ngasemva okanye zicocwe ngezinyibilikisi, zenze ukuba zisetyenziswe kwakhona ixesha elide.

Isicelo :

Ezi zakhiwo zenza izihluzi zensimbi engenasici zibe lukhetho oludumileyo kwizicelo ezininzi kwirhasi yemizi-mveliso kunye nokucoca ulwelo, kubandakanya:

*Ukuhluzwa kwerhasi:

Ukususa uthuli, amasuntswana, kunye nezinto ezingcolisa umoya kunye nemijelo yerhasi kwiinkqubo ezahlukeneyo zamashishini, kubandakanya ukuhluzwa komoya ocinezelweyo,

ukuhluzwa kwegesi yendalo, kunye nokucoca umoya wesixhobo.

* Ukuhluzwa kolwelo:

Ukucoca amasuntswana, iibhaktheriya, kunye nolunye ungcoliseko kulwelo olusetyenziswa ekusetyenzweni kweekhemikhali, ukutya kunye nokuveliswa kwesiselo,

amayeza, kunye nonyango lwamanzi.

* Ukuhluzwa kweoyile kunye namafutha:

Ukususa ukungcola kunye nokungcola kwi-oyile yokuthambisa, i-hydraulic fluids, kunye namafutha okukhusela izixhobo kunye nokuqinisekisa ukusebenza ngokufanelekileyo.

Ukongeza kwezi zicelo ziqhelekileyo, izihluzi zensimbi engenastainless sintered zikwasetyenziswa kwiinkqubo ezahlukeneyo zokuhluza ezikhethekileyo kwimizi-mveliso, kubandakanya:

* I-Catalyst recovery:Ukubuyisela ii-catalysts ezixabisekileyo kwimixube yokusabela kwiinkqubo zokuvelisa imichiza.

* Ukuvalwa:Ukucoca izisombululo kunye negesi kumashishini amayeza kunye ne-biotechnology.

* Ulawulo lokukhupha:Ukususa i-particle kunye nongcoliseko kwimisinga yerhasi ukuthobela imimiselo yokusingqongileyo.

2. Izihluzi zeSintered Mesh zentsimbi engatyiwayo

Izihluzi zensimbi engenastainless sintered mesh luhlobo lwemithombo yeendaba yokucoca esetyenziswa kakhulu kushishino lokutya nesiselo ngenxa

iimpawu zabo ezizodwa. Zenziwa ngokudibanisa iileya zomnatha omncinci wentsimbi engenastainless kunye ngobushushu obuphezulu

inkqubo ye-sintering, ngaphantsi kwendawo yokunyibilika kwentsimbi. Le nkqubo idala ubume obuqinileyo, ubume besinyithi obunobukroti obubonelela ngeenzuzo ezininzi eziphambili:

Iimpawu eziphambili :

* Amandla aphezulu kunye nokuqina:

* Ukumelana nokugqwesa okugqwesileyo:

* Ukucoca ngokulula:

Ezi zakhiwo zenza izihluzi zensimbi ezingenasici zilukhetho oludumileyo kwizicelo ezahlukeneyo ekutyeni nasekuhluzweni kwesiselo, kubandakanya:

Isicelo :

* Ukucaciswa kolwelo:

* Ukuhluzwa kwangaphambili kweenwebu:

* Ukuhluzwa kwamanzi:

* Ukuhluzwa kweesyrups kunye neoyile:

* Ukuhluzwa komoya kunye negesi:

3. Izihluzi zeBronzi Sintered

Iifilitha ze-bronze sintered zolunye uhlobo lwemidiya yokucoca isinyithi esetyenziswa kwizicelo zamashishini. Zenziwa ngenkqubo efanayo

njengezihluzi zensimbi ezingenasici, kodwa endaweni yomgubo wensimbi, i-alloy powder isetyenziswe njengesiseko sezinto. Nantsi ukwahlukana kwabo

iimpawu kunye nenkqubo yokuvelisa:

Iimpawu eziphambili :

Iimpawu:

* Isebenza kakuhle emalini:

2. Ukubumba:

3. Sintering:

4. Ukuhlawula kunye nokugqiba:

Isicelo :

Ngenxa yeempawu zazo, izihluzi ze-bronze sintered zifumana usetyenziso oluqhelekileyo kumandla olwelo kunye neenkqubo zolwelo lwamanzi:

* Ukuhluzwa kolwelo olusebenza ngolwelo lolwelo:

* Uhluzo lwenkqubo yokuthambisa:

* Uhluzo lomoya:

Ngelixa izihluzi zobhedu zibonelela ngesisombululo esinexabiso eliphantsi kuninzi lwamandla olwelo kunye nosetyenziso lwehydraulic, kubalulekile ukuba

qwalasela imida yabo ngokubhekiselele kwi-corrosion resistance xa kuthelekiswa nezihluzo zensimbi ezingenasici kwizicelo ezibandakanya iikhemikhali ezinzima okanye iindawo ezisingqongileyo.

4. Izihluzi zeSintered Polyethylene:

Isishwankathelo:

Iimpawu kunye neeNzuzo:

* Ukumelana neekhemikhali eziphezulu kwizinyibilikisi zendalo kunye neeasidi.

* Ikhaphukhaphu kwaye ineendleko ezifanelekileyo.

* I-Biocompatible, ibenza bafanelekele usetyenziso lwamayeza athile.

* Ilungele ukuhluzwa komoya kunye nerhasi.

Isicelo

Ukusetyenziswa kuShishino lwezamayeza kunye neBiotechnological Industries:

5. Izihluzi zeglasi eSintered:

Iipropati zeSintered Glass:

Iimbonakalo:

* Ukumelana neekhemikhali okugqwesileyo kuluhlu olubanzi lweekhemikhali.

* Ukuzinza okuphezulu kwe-thermal, okuvumela ukusetyenziswa kumaqondo aphezulu.

* Inert kwaye ingasetyenziselwa ukuhluza okungenazintsholongwane.

* Ukusebenza kokucoca okuphezulu kumasuntswana amahle.

Isicelo:

Usetyenziso oluQhelekileyo kwiLabhoratri kunye noVavanyo lokusiNgqongileyo:

6. Izihluzo ze-Sintered ezisekelwe kwi-nickel:

Ukuqulunqwa kunye neempawu:

Ubunakho bobushushu obuphezulu, bubenza bafanelekele iindawo ezifunayo.

Amandla omatshini alungileyo kwizicelo zoxinzelelo oluphezulu.

Usetyenziso

Ukusetyenziswa kubushushu obuphezulu kunye neeNdawo eziTshayo:

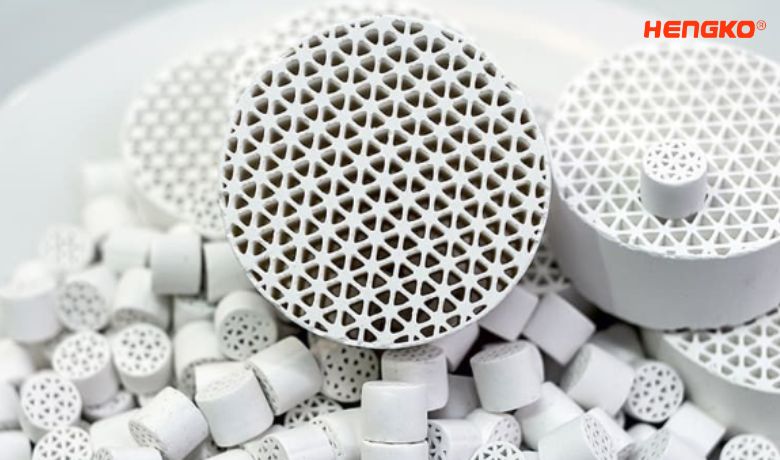

7. Izihluzi zeSintered Ceramic:

Iimpawu eziphambili kunye nokuqina:

Isicelo

Usetyenziso kwiMetal Casting kunye nokuCocwa koMoya:

8. Izihluzi ze-Titanium Sintered:

Izibonelelo, iimpawu, kunye neePropati zokuChasa:

Izihluzi ze-Titanium-sintered zinika indibaniselwano ekhethekileyo yamandla aphezulu, ukumelana nokugqwesa okugqwesileyo, kunye

Isicelo

Ukusetyenziswa okuKhethekileyo kuShishino lweMichiza kunye nakumaShishini aseLwandle:

9. Izihluzo zeSilver eziSintered:

Iipropati eziZodwa, iiMpawu, kunye neNtsebenzo:

Izihluzi zesilivere zeSintered ziyamangalisa kwiipropathi zazo zendalo ze-antimicrobial.

Usetyenziso:

Ukusetyenziswa kuCwangciso lwaManzi kunye nokuHluzwa kweAntimicrobial:

Ezi zihluzo zifanelekile kwiinkqubo zokucoca amanzi kwindawo yokusetyenziswa kunye nezicelo ezifunayo

10. Izihluzo zeKhabhoni eziSebenzisiweyo eziSintered:

Ukuqulunqwa, Iimpawu, kunye neZakhono zokuHlunga:

Ezi zihluzo zidibanisa isakhiwo sesinyithi esine-sintered kunye ne-carbon granules edibeneyo esebenzayo.

Izicelo zokuCoca igesi kunye noLawulo lwevumba:

Izihluzi zekhabhoni ezifakwe kwi-sintered ziqeshwe kwiinkqubo zokucoca umoya kunye negesi ukususa iigesi ezingafunekiyo,

5-Izinto omele uzikhathalele xa ukhetha okulungileyoIsihluzo seSintered

Ukukhetha isihluzo esifanelekileyo se-sintered kwisicelo sakho somzimveliso kufuna uqwalaselo ngononophelo lwemiba emininzi:

1. Ukalisho lweMicron:

Oku kubhekisa kubungakanani bamasuntswana isihluzo esinokuwabambisa. Khetha ukalisho lwemicron oluncinci kunamasuntswana ofuna ukuwasusa.

2. Ukuhambelana kwezinto:

Isixhobo sokucoca kufuneka sihambelane nolwelo oluya kubonakaliswa kulo. Insimbi engenasici lukhetho oludumileyo

ngenxa yokumelana ne-corrosion, kodwa ezinye iinketho ezifana ne-bronze okanye i-nickel zinokufaneleka ngokuxhomekeke kwisicelo.

3. Ubushushu kunye noxinzelelo:

Isihluzi sifuna ukumelana nobushushu bokusebenza kunye noxinzelelo lwenkqubo yakho.

4. Izinga lokuhamba:

Isihluzi kufuneka sivumele ukuhamba kwamanzi okwaneleyo ukuhlangabezana neemfuno zakho zenkqubo ngelixa ugcina ukuhluzwa okusebenzayo.

5. Ukucoca kunye nokugcinwa:

Cinga ukuba kuya kuba lula kangakanani ukucoca nokugcina isihluzo. Ukuhlamba umva okanye amandla okuhlaziya anokuthi

kubalulekile kwezinye izicelo.

Ngokuphonononga ngononophelo ezi khrayitheriya, unokukhetha isihluzo esine-sintered esongeza inkqubo yakho yeshishini

kwaye iqinisekisa ukuhluzwa okusebenzayo, okuthembekileyo.

Qhagamshelana noHENGKO

Ukuba ufuna iingcebiso ezineenkcukacha ngakumbi okanye unqwenela ukuxoxa ngeemfuno zakho zokuhluza,

Thumela umyalezo wakho kuthi:

Ixesha lokuposa: Apr-26-2024