-

HENGKO® High Purity Semiconductor Gas Filter

Izihluzi zoluhlu oluphezulu zokucoceka ziyilelwe ukuhluza iigesi ze-semiconductor.Le ndibano edibeneyo edibeneyo iya kuzisa i-0.003 micron particle incediswe ukugcinwa.Semi...

Jonga iinkcukacha -

ISintered In-line yeSihluzo segesi yeMetal yeSemiconductor yeSistim yokuCoca igesi

Izihluzi zegesi yentsimbi e-Sintered emgqeni zisebenza ukukhupha ukungcola okubandakanya ukufuma, ioksijini, ikharbon diokside, icarbon monoxide, iihydrocarbons kunye neekhabhoni zetsimbi nge ...

Jonga iinkcukacha -

I-HENGKO ePhakamileyo ecocekileyo yeNgxowa-mali ye-Metal Diffusers Ilitye lokuhluza igesi ecocekileyo ...

I-HENGKO i-Porous Metal Diffusers ngokukhawuleza ikhupha amagumbi okufunxa emoyeni eyehlisa ixesha lomjikelo kwaye inyuse ukuphuma.Intsimbi yethu engenastainless diffu...

Jonga iinkcukacha -

Ubushushu kunye neSensom yokufuma kwiSemiconductor yeGumbi eliCocekileyo loBuqondo boBubushushu beContr...

Umboniso weMveliso Ubushushu kunye nokufuma kwendawo ecocekileyo kumiselwa ikakhulu ngokweemfuno zenkqubo, kodwa phantsi kwemeko yokuhlangana...

Jonga iinkcukacha -

I-Sintered SS 316L yentsimbi engenamlilo-ubungqina bokukhusela isihluzo sezindlu zomzi-mveliso...

Iindibano zenzwa zobungqina bokuqhuma zenziwe nge-316 yensimbi engenasici yokukhusela ubuninzi be-corrosion.Isibambi somlilo esibophelelekile sibonelela ngokusasazwa kwerhasi...

Jonga iinkcukacha -

316L isihluzi somlilo-ubungqina bezindlu zokuhlala co2 semiconductor microns modbus sensor filter probe ho...

I-HENGKO i-sensor ye-explosion-proof sensor housing yenziwe nge-316L yensimbi engenasici kunye ne-aluminiyam yokukhusela ubuninzi bomhlwa.Umntu obambe idangatye elibotshwe sinter ubonelela ...

Jonga iinkcukacha

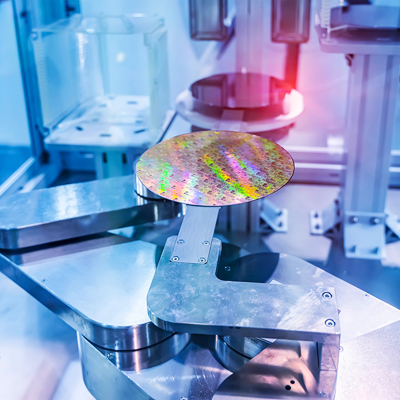

Izihluzi zegesi yeSemiconductor:

Ukuqinisekisa Ukucoceka kweGesi eNgafezekiyo kwiChipmaking

Kwihlabathi elintsonkothileyo lokwenziwa kwe-semiconductor, apho ukuchaneka kunye nokucoceka kubaluleke kakhulu, umgangatho we

iigesi ezisetyenzisiweyo zidlala indima ebalulekileyo ekuqinisekiseni impumelelo yale nkqubo.Ukungcola, nokuba kumanqanaba angenasiphelo,

inokwenza umonakalo kwiisekethe eziethe-ethe zeemicrochips, zizenze zibe nesiphene kwaye zingasebenziseki.Ukukhusela

Le nkqubo ibalulekileyo, izihluzi zegesi zesemiconductor zime njengabagcini abangayekeleliyo, zisusa ngobuchule izinto ezingcolisayo.

kunye nokuqinisekisa umgangatho ococekileyo weegesi ezihamba kwimizila yokuvelisa.

Zininzi iimpawu ezigqwesileyo kunye noncedo lwezihluzo zetsimbi zetsimbi

1. Yenziwe kwiNdawo yoBume beGumbi ecocekileyo

Ezi zihluzo zizalelwa kwindawo yococeko yangoku, indawo apho iimeko ezisulungekileyo zigcinwa ngobuchule ukuze kuncitshiswe nakuphi na ukungcoliseka okunokwenzeka.Bangena kwinkqubo yokwenziwa engqongqo, eqala ngokuchaneka ukuwelda phantsi komoya ocociweyo.Ukugungxulwa kwamanzi okulandela emva koko, okulandelwa nguxinzelelo oluphezulu, ukucocwa kwenitrogen ehluziweyo, kuphelisa nawaphi na amasuntswana ahlala kwaye kunciphisa umngcipheko wokuchithwa kwamasuntswana.

2. Ubuchule obukhethekileyo bokususwa kweNcam

Ngobuchule obumangalisayo bokuhluza okumangalisayo kwe-9 LRV ye-0.003μm yamasuntswana, ngokubambelela kwimigangatho engqongqo ebekwe yi-SEMI F38 kunye ne-ISO 12500 iindlela zovavanyo, ezi zihluzo zisusa ngokufanelekileyo nawaphi na amasuntswana awenziwe ngumhlwa kunye namasuntswana avela kwiindawo ezihambayo, eqinisekisa ukucoceka okucocekileyo kobume. iigesi.

3. Amandla oMsebenzi oPhezulu

Zivavanywe ngokungqongqo ukuqinisekisa ukomelela okukhethekileyo kwiinkqubo zokwenziwa kwemfuno kunye nemo engqongileyo ehlala isebenzisa uxinzelelo oluphezulu lwerhasi, ezi zihluzo zibonelela ngokusebenza okungagungqiyo kubo bonke ubomi babo.

4. Ukugqitha kweyona Migangatho iPhezulu yoShishino

Ukodlula iimfuno ezingqongqo zokuphathwa kwerhasi yokuhluza ukusetyenzwa kwe-semiconductor, ezi zihluzo zivavanywa ngokuqatha ukuqinisekisa ukuba ziyahlangabezana nokusebenza okubalulekileyo kokucoca, ulawulo lokuhamba oluchanekileyo, kunye nemigangatho yokhuseleko efunwa ziinkqubo zokuhanjiswa kwegesi kwimveliso ye-semiconductor.

5. UkuZibophelela okungagungqiyo kuKhuseleko

Ukukhusela ekuvezweni kwigesi enokutsha, eyonakalisayo, enetyhefu, kunye nepyrophoric, izihluzi zezindlu zivavanywa ngobuchule bokuvuza, ziqinisekisa ukuba zifikelela kwinqanaba elimangalisayo lokuvuza elingaphantsi kwe-1x10-9 atm scc/sesibini.Oku kuzibophelela okungagungqiyo kukhuseleko kuqinisekisa ukuba iigesi eziyingozi zigcinwe kwaye zithintelwe ukuba zibangele ingozi.

6. Ukucoceka okungaguqukiyo kwi-Chipmaking Excellence

Ngobuchule bazo obukhethekileyo bokuhluza, ukuzinikela okungagungqiyo kukhuseleko, kunye nokubambelela kweyona migangatho iphezulu yoshishino, ezi zihluzo zerhasi zidlala indima ebalulekileyo ekukhuseleni inkqubo entsonkothileyo yokwenziwa kwe-semiconductor.Bema njengabagcini bobunyulu, beqinisekisa ukuba kuphela ezona gesi zicocekileyo zihamba kwimizila yokuvelisa, zivula indlela yokudala ii-microchips ezisebenza ngokuphezulu ezinamandla kwihlabathi lethu lanamhlanje.

Iintlobo zeeFilters zeSemiconductor

Izihluzi zeSemiconductor zisetyenziswa kwizicelo ezahlukeneyo, kubandakanya:

* Ukwenziwa kombane:

Izihluzi ze-Semiconductor zisetyenziselwa ukususa amasuntswana kumanzi aphezulu, iigesi, kunye neekhemikhali ezisetyenziselwa ukwenziwa kwee-semiconductors.

* Ukucwangciswa koomatshini beMichiza (CMP):

Izihluzi zeSemiconductor zisetyenziselwa ukususa amasuntswana kwi-CMP slurries, asetyenziselwa ukupolisha iiwafers zesemiconductor.

* I-Biomedical:

Izihluzi zeSemiconductor zisetyenziselwa ukususa amasuntswana kulwelo olusetyenziswa kuxilongo lwezonyango kunye nonyango.

* Okusingqongileyo:

Izihluzi zeSemiconductor zisetyenziselwa ukususa amasuntswana emoyeni nasemanzini.

Kukho iintlobo ezine eziphambili zezihluzi ze-semiconductor:

1. Izihluzi zeMembrane:

Izihluzi zeMembrane zenziwe ngefilim ebhityileyo, enemingxuma evumela ulwelo ukuba ludlule xa kubanjwa amasuntswana.

2. Izihluzi ezinzulu:

Izihluzi ezinzulu zenziwe ngebhedi eshinyeneyo, evuthuzayo yemathiriyeli ethi ibambe amasuntswana njengoko equkuqela kwisihluzo.

3. Izihluzi ze-Adsorbent:

Izihluzi ze-Adsorbent zenziwe ngezinto ezitsala kwaye zibambe amasuntswana.

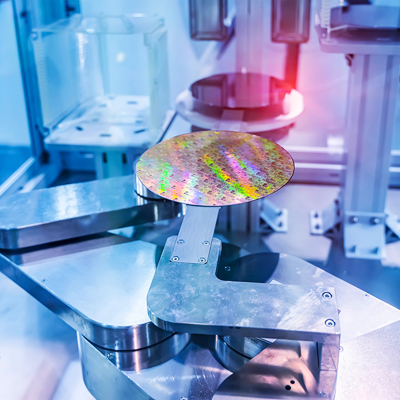

4. Izihluzi zetsimbi zentsimbi

Izihluzi zetsimbi zetsimbi luhlobo lwesihluzo sobunzulu esiqhele ukusetyenziswa kwimveliso ye-semiconductor.Zenziwa ngokufaka umgubo wesinyithi ocolekileyo kwisakhiwo esinemingxuma.Izihluzi zetsimbi zetsimbi zaziwa ngokuqina kwazo okuphezulu, ukusebenza kakuhle kokucoca, kunye nokukwazi ukumelana nobushushu obuphezulu kunye noxinzelelo.

Izinto eziluncedo kwizihluzi zetsimbi zentsimbi zokwenza isemiconductor:

* Ukuqina okuphezulu:

* Ukusebenza kakuhle kokucoca:

* Ubomi obude:

* Ukuhambelana kweMichiza:

Ukusetyenziswa kwezihluzo zetsimbi ezifakwe kwi-semiconductor:

* Ukucocwa kwegesi:

Izihluzi zetsimbi ezifakwe kwi-Sintered ziyinxalenye ebalulekileyo yenkqubo yokuvelisa i-semiconductor, inceda ukuqinisekisa ukuveliswa kwezixhobo eziphezulu ze-semiconductor.

Uhlobo lwesihluzo se-semiconductor esisetyenziswe kwisicelo esithile sixhomekeke kubukhulu beengqungquthela ezikhutshwayo, uhlobo lolwelo oluhluzwayo, kunye nenqanaba elifunwayo lokuhluzwa.

Nantsi itheyibhile eshwankathela iindidi ezahlukeneyo zezihluzi zesemiconductor:

| Uhlobo lwesihluzi | Inkcazo | Usetyenziso | Umfanekiso |

|---|---|---|---|

| Izihluzi zeMembrane | Yenziwe ngefilimu ebhityileyo, enemingxuma evumela ulwelo ukuba ludlule ngelixa ubambe amasuntswana. | Imveliso yombane, i-CMP, i-biomedical, indalo | |

| Izihluzi ezinzulu | Yenziwe ngebhedi eshinyeneyo, ene-tortuous ngezinto ezibamba amasuntswana njengoko equkuqela kwisihluzo. | I-CMP, i-biomedical, indalo | |

| Izihluzi ze-Adsorbent | Yenziwe ngezinto ezitsala kwaye zibambe amasuntswana. | Imveliso yombane, i-CMP, i-biomedical, indalo | |

| Izihluzi zetsimbi zentsimbi | Yenziwe ngokucoca umgubo wesinyithi ocolekileyo kwisakhiwo esinemingxuma. | Ukucocwa kwerhasi, ukuhluzwa kweekhemikhali, ukuhluzwa kwamanzi acocekileyo, ukuhluzwa kodaka lweCMP | Izihluzi zetsimbi ze-Sintered ze-semiconductor |

Isicelo

Izihluzi zegesi ze-sintered semiconductor zegesi zisetyenziswa ngokubanzi kwiinkqubo ezahlukeneyo kwishishini le-semiconductor.Iimpawu zabo ezikhethekileyo, ezifana nokusebenza kakuhle kokucoca, ukuqina, kunye nokukwazi ukumelana nokushisa okuphezulu kunye noxinzelelo, kubenza babe yinxalenye ebalulekileyo yeenkqubo zokuhanjiswa kwegesi kwimveliso ye-semiconductor.

Nazi ezinye zezicelo ezikhethekileyo zokucoca igesi yentsimbi esemiconductor:

1. Imveliso yewafer:

Izihluzi zetsimbi zetsimbi zisetyenziselwa ukucoca iigesi ezisetyenziselwa ukuveliswa kwe-wafer, njenge-nitrogen, i-hydrogen, kunye ne-oxygen.Ezi gesi zibalulekile kwiinkqubo ezifana nokukhula kwe-epitaxial, i-etching, kunye ne-doping.

2. Ukuhluzwa kweekhemikhali:

Izihluzi zetsimbi zetsimbi zisetyenziselwa ukuhluza iikhemikhali ezisetyenziswa kwimveliso ye-semiconductor, njengeeasidi, iziseko, kunye nezinyibilikisi.Le michiza isetyenziselwa iinjongo ezahlukeneyo, eziquka ukucoca, ukukrolwa, kunye nokupholisha.

3. Ukuhluzwa kwamanzi acocekileyo:

Izihluzi zetsimbi ezifakwe kwi-Sintered zisetyenziselwa ukucoca amanzi e-ultrapure (UPW) asetyenziswa kwimveliso ye-semiconductor.I-UPW ibalulekile ekucoceni nasekuhlambululeni ii-wafers, kunye nokulungiselela imichiza.

4. Uhluzo oluludaka lwe-CMP:

Izihluzi zetsimbi ezisiyiweyo zisetyenziselwa ukuhluza i-slurries ye-CMP, esetyenziselwa ukupolisha ii-wafers ze-semiconductor.I-CMP yinkqubo ebalulekileyo ekwenziweni kwee-microchips.

5. Uhluzo lwendawo yokusetyenziswa (POU):

Izihluzi zetsimbi ezifakwe kwi-Sintered zihlala zisetyenziswa njengezihluzi ze-POU, ezifakwe ngokuthe ngqo kwindawo yokusetyenziswa ukubonelela ngelona nqanaba liphezulu lokuhluza.Izihluzi ze-POU zibaluleke kakhulu kwizicelo apho ukucoceka kwegesi kubaluleke kakhulu, njengokwenziwa kwee-microprocessors kunye nezinye izixhobo zokusebenza okuphezulu.

6. Ukuphathwa kwerhasi ecocekileyo:

Izihluzi zetsimbi ezifakwe kwi-sintered zisetyenziselwa kwiinkqubo zokuphatha i-gas ezicocekileyo ukususa ukungcola kwiigesi ezisetyenziselwa ukuveliswa kwe-semiconductor.Ezi zingcolisi zingabandakanya amasuntswana, ukufuma, kunye ne-organic compounds.

7. Ukwenziwa kweMicroelectronics:

Izihluzi zetsimbi zetsimbi zisetyenziselwa ukwenziwa kwee-microelectronics, ezinjengeekhompyuter, iitafile, iiselfowuni, i-IoT sensors, kunye nezixhobo zokulawula.

8. Uhluzo lweMicro-electromechanical systems (MEMS):

Izihlungi zetsimbi ezifakwe kwi-Sintered zisetyenziselwa ukuhluzwa kwe-MEMS, okuyinkqubo yokususa ukungcola kwiinkqubo ze-micro-electromechanical.I-MEMS isetyenziswa kwiinkqubo ezahlukeneyo, kubandakanywa izinzwa, ii-activators, kunye nee-transducers.

9. Uhluzo lwesixhobo sogcino lwedatha:

Izihluzi zetsimbi zetsimbi zisetyenziselwa ukuhluzwa kwesixhobo sogcino lwedatha, okuyinkqubo yokususa ungcoliseko kwizixhobo zokugcina idatha, ezinje ngee-hard drives kunye ne-slid-state drives.

Ukongeza kwezi zicelo zikhethekileyo, izihluzi zegesi ze-sintered semiconductor zensimbi nazo zisetyenziswa kwiintlobo ngeentlobo zezicelo kwishishini le-semiconductor.Ukuguquguquka kwabo kunye nokuthembeka kwabo kubenza babe sisixhobo esibalulekileyo kubenzi be-semiconductor.

Ngaba ujonge izihluzi zegesi ezikumgangatho ophakamileyo we-sintered metal semiconductor?

I-HENGKO liqabane lakho lokuya kwi-OEM yezisombululo kwiinkqubo zokwenziwa kwe-semiconductor.

Izihluzi zethu ezenziwe ngobunjineli ezichanekileyo ziqinisekisa ukuthembeka kunye nokusebenza kakuhle kwiinkqubo zakho, zikunika umda kwimarike yokhuphiswano.

Kutheni ukhetha izihluzi zikaHENGKO?

* Umgangatho ophezulu kunye nokuqina

* Izisombululo ezenzelwe wena ukuze zilungele iimfuno zakho ezithile

* Ukusebenza okuphuculweyo kwimveliso ye-semiconductor

Musa ukuvumela imiceli mngeni yokucoca ibambe imveliso yakho.

Xhumana nathi namhlanje ukuze ujonge ukuba izihluzi zethu zetsimbi ezifakwe emanzini zinokuyiguqula njani inkqubo yakho yokuvelisa.

Qhagamshelana nathi kuka@hengko.com

Iqabane kunye ne-HENGKO kwaye uthathe inyathelo lokugqwesa kwimveliso ye-semiconductor!