Yintoni iSintering?

Ukuthetha ngokulula, i-Sintering yinkqubo yonyango lobushushu esetyenziselwa ukuguqula izinto ezinomgubo zibe bunzima obuqinileyo, ngaphandle kokufikelela kwinqanaba lokunyibilika okupheleleyo.

Olu tshintsho lwenzeka ngokufudumeza izinto ezingaphantsi kwendawo yokunyibilika kuze kube yilapho iinqununu zayo zihambelana nomnye. I-Sintering isetyenziswa kakhulu kumashishini ahlukeneyo afana nesinyithi, iiseramikhi, kunye noshicilelo lwe-3D ukuvelisa imathiriyeli eshinyeneyo neyomeleleyo ukusuka kumgubo.

Kodwa ngaba ubusazi ukuba ingcamango yokucula asiyonto yanamhlanje?

Enyanisweni, imvelaphi yayo inokulandelwa ukuya malunga ne-3000 BC, xa yayisetyenziselwa ukwenza izinto ze-ceramic. Ukuqonda kwale mihla kwezenzululwazi kunye nokusetyenziswa kwemizi-mveliso okuxhaphakileyo kwe-sintering, nangona kunjalo, kuphuhliswe kakhulu kwinkulungwane edlulileyo.

Njengoko unokucinga, ukucula kudlala indima ebalulekileyo kubuninzi bezicelo. Ukusukela ekwenzeni iiplagi zentlantsi, iicapacitors zeceramic, kunye nezithsaba zamazinyo ukuya kulwakhiwo lwezixhobo zobugcisa obuphezulu, ukufakwa kwentsimbi kungqineke kuyinto eyimfuneko.

Iindidi ezahlukeneyo zeSintering

Ngoku uyazi ukuba yintoni i-sintering kwaye isetyenziswe njani kwimbali yonke, lixesha lokukwazisa kwiindidi ezahlukeneyo zokucula. Ewe, zininzi iindlela zokucula!

Okokuqala phezului-slid-state sintering. Olu hlobo lolona hlobo lusisiseko kunye noluqhelekileyo lwe-sintering. Apha, i-powder material ishushu kuze kube yilapho iincinci ziqala ukudibanisa. Kufana nendlela onokuthi wakhe ngayo inqaba yesanti – iinkozo zesanti ziyanamathelana, kodwa azinyibiliki.

Okulandelayo,sinolwelo isigaba sintering. Olu hlobo lubandakanya umxube wezinto ezimbini okanye ngaphezulu. Umxube ufudunyezwe ukuya kwindawo apho enye yezinto iyancibilika kwaye yenza isigaba solwelo, esinceda ekudibaniseni amasuntswana asele eqinile kunye.

Isithathukuluhlu ivuliwe sintering. Kule meko, i-additive okanye i-catalyst isetyenziselwa ukukhawuleza inkqubo ye-sintering. Yicinge njengokongeza igwele kwintlama - yenza ukuba isonka sinyuke ngokukhawuleza.

Okokugqibela,kukho iindlela zokucofa ezincedisa uxinzelelo ezifana nokucofa okushushu kunye ne-spark plasma sintering. Njengoko igama libonisa, obu buchule busebenzisa uxinzelelo ngokudibanisa nobushushu ukukhawulezisa inkqubo ye-sintering kunye nokuvelisa izinto ezixineneyo.

Uhlobo ngalunye lwe-sintering luneseti yalo yeenzuzo kwaye lusetyenziselwa izicelo ezithile. Ukhetho luxhomekeke kwizinto ezifana nempahla esetyenziswayo, iimpawu ezinqwenelekayo zemveliso yokugqibela, kunye nezixhobo ezikhoyo. Kumacandelo azayo, siza kuphonononga nzulu kwimathiriyeli ethile ene-sintered kunye nenkqubo ye-sintering ngokwayo.

Hlala ubukele ukufumana ulwazi olunomdla kwihlabathi le-sintering!

Ukuphonononga iSintered Materials

Emva koko Okulandelayo kufuneka siqonde iintlobo ezahlukeneyo zemathiriyeli ye-sintered.

Ndiqinisekile ngoku, ufumana ukuxhoma kwenkqubo yokucula. Kodwa kuthekani ngemveliso yale nkqubo ibangel’ umdla?

Enye yezinto eziqhelekileyo eziveliswa yintsimbi ye-sintered.Inkqubo ibandakanya ukudibanisa kunye nokwenza umgubo wesinyithi phantsi kobushushu, ukuyijika ibe yintsimbi eqinileyo. Isiphumo sisinyithi esinezinga eliphezulu lokucoceka kunye nokufana. Isinyithi esine-Sintered sinokufumaneka kumashishini ahlukeneyo, ukusuka kumacandelo eemoto ukuya kwii-implants zonyango, ngenxa yokuqina kwayo kunye nokuguquguquka.

Okulandelayo,makhe sithethe ngelitye eline-sintered. Ilitye le-Sintered iveliswa ngokufaka ukushisa kunye noxinzelelo kwiiminerali zendalo, udongwe, kunye ne-feldspar, ukudala into ephantse ibe yinto engapheliyo. Uyakuhlala ufumana ilitye eline-sintered kwiindawo ezinetrafikhi ephezulu njengeekhawuntara zasekhitshini okanye iithayile zegumbi lokuhlambela, apho ukuqina ngundoqo.

I-Sintering ikwadlala indima ebalulekileyo kwiiseramikhi. Inkqubo isenza sikwazi ukubumba iiseramikhi zibe yintaphane yeemilo ezinejiyometri ezintsonkothileyo ezingenakukwazi ukwenzeka ngeendlela zemveli. Ukusuka kwiithayile zeceramic ukuya kwingqayi yodongwe, ukufakwa kwentsimbi kube nefuthe lenguquko kweli candelo.

Okokugqibela,kukho ezinye izinto ezahlukeneyo ezikhethekileyo ze-sintered zokuphononongwa. Ezi zivela kwizinto ezidibeneyo, ezifana ne-metal-ceramic composites, ukuya kwizinto ezisemgangathweni ezisebenzayo, apho ukwakheka kuyahluka kulo lonke icandelo.

Inkqubo yeSintering Icacisiwe

Masiqhubele phambili ukusuka kwiimveliso ukuya kwinkqubo ngokwayo. Kwenzeka njani ukuba sintering, kwaye ngawaphi amanqanaba aphambili abandakanyekayo?

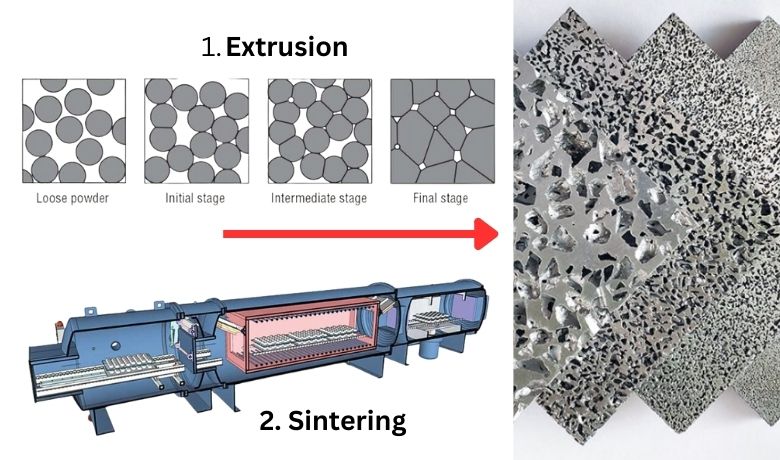

Ukuqala, amanyathelo angaphambili abalulekile. Impahla ekrwada, nokuba yintsimbi, i-ceramic, okanye ngenye indlela, kufuneka ilungiswe ibe ngumgubo. Lo mgubo uye umiliselwe kwimo efunwayo, rhoqo ngenkqubo ebizwa ngokuba 'yi-green compacting'.

Okulandelayo kuza intliziyo yokusebenza: inkqubo ye-sintering. I-powder emile ifudunyezwa kwindawo elawulwayo, ngokuqhelekileyo isithando somlilo, kwiqondo lokushisa elingaphantsi kwendawo yokunyibilika kwayo. Oku kuvumela amaqhekeza ukuba adibanise ngaphandle kokunyibilika ngokupheleleyo, enze ubunzima obuqinileyo.

Emva kokuba inkqubo ye-sintering igqityiwe, izinto eziphathekayo zingena kwisigaba sokupholisa. Oku kufuneka kulawulwe ngononophelo, njengoko ukupholisa ngokukhawuleza kunokukhokelela ekuqhekekeni okanye eminye imiba yesakhiwo. Ukupholisa ngokucothayo kuvumela umbandela ukuba uzinze kwaye uqine ngokufanelekileyo.

Okokugqibela,asinakukwazi ukulibala izinto ezichaphazela i-sintering, ngokukodwa, ubushushu kunye nexesha. Ubushushu be-sintering kufuneka buphakame ngokwaneleyo ukuququzelela ukuhlangana kodwa sezantsi ngokwaneleyo ukunqanda ukunyibilika okupheleleyo. Ngokufanayo, ixesha elichithwa yimathiriyeli kwinkqubo ye-sintering inokuchaphazela kakhulu iipropathi zemveliso yokugqibela.

Kwinxalenye elandelayo yesaga yethu yokuntywila, siya kuntywila nzulu kwizihluzi ezifakwe kwi-sintered kwaye sityhile iimeko ezifunekayo zokutshiza. Ngoko hlala ubukele!

Izihluzi ze-Sintered: I-Spotlight Spotlight

Sele sigubungele iziseko zokucula, saphonononga iintlobo ngeentlobo zemathiriyeli ye-sintered, kwaye saxoxa ngenkqubo ye-sintering ngokweenkcukacha.

Ngoku, makhe siqwalasele kwi-ausetyenziso oluthile lwezihluzi zokucoca.

Mhlawumbi esinye sezona zicelo ziqaphelekayo ze-sintering kukwenza izihluzo zetsimbi ezine-sintered. Ezi zihluzo ziveliswa kumgubo wesinyithi, zicudiwe kwaye zifakwe i-sintered ukwenza i-porous kodwa esomeleleyo isihluzo esiphakathi. Ubungakanani bepore yezi zihluzo zinokulawulwa ngokuchanekileyo, ukunika amandla okucoca aphezulu xa kuthelekiswa nezihluzo zemveli zocingo olulukiweyo.

Usenokuzibuza,kutheni ukusebenzisaizihluzi zetsimbi zentsimbi?Impendulo ixhomekeke ekomeleleni kwazo kunye nokuxhathisa amaqondo obushushu aphezulu kunye noxinzelelo. Ezi zakhiwo zenza ukuba izihluzi zetsimbi zetsimbi zibe yimfuneko kumashishini ukusuka kumayeza ukuya kwiikhemikhali zepetroli kunye nokuveliswa kokutya nesiselo.

Olunye usetyenziso olunomdla lokuntywila ekuhluzweni sisihluzo seglasi esine-sintered. Ezi zenziwa ngokudibanisa amasuntswana eglasi amancinane kumaqondo obushushu aphezulu. Zihlala zisetyenziswa kwiilabhoratri zokuhluza kunye nokuhanjiswa kwerhasi ngenxa yokuxhathisa okuphezulu kweekhemikhali kunye nobukhulu obuchanekileyo bepore.

Izihluzi ze-Sintered, nokuba yintsimbi okanye iglasi, ngumzekelo wokukwazi ukwenza i-sintering ekudaleni izinto eziphezulu kunye neenzuzo ezihlukeneyo.

Ukuqonda iSintering Conditions

Ngoku, makhe siphendulele ingqalelo yethu kwiimeko ze-sintering. Xa sithetha ngenkqubo ye-sintering, iimeko ezenzeka phantsi kwazo zibaluleke kakhulu.

Okokuqala,ubushushu be-sintering budlala indima ebalulekileyo kwinkqubo. Kufuneka ibe ngaphantsi kwendawo yokunyibilika kwezinto, ukuvumela amaqhekeza ukuba adibanise ngaphandle kokunyibilika ngokupheleleyo. Yibhalansi eethe-ethe enokuthi ichaphazele kakhulu umgangatho wemveliso yokugqibela.

Emva kokokukho umba wegesi. Usenokuba uyazibuza, "Yeyiphi irhasi esetyenziswayo kwi-sintering?" Ngokuqhelekileyo, i-sintering iqhutyelwa kwi-atmosphere elawulwayo ukukhusela ukuphendula okungafunekiyo phakathi kwezinto kunye neegesi ezijikelezileyo. Ngokuqhelekileyo, iigesi ze-inert ezifana ne-nitrogen okanye i-argon zisetyenziswa, nangona ukhetho oluthile luxhomekeke kwizinto eziphathekayo.

Uxinzelelo nalo luza kudlala, ngakumbi kwiindlela zokuncedisa uxinzelelo. Uxinzelelo oluphezulu lunokubangela izinto ezixineneyo, njengoko amasuntswana anyanzelwa ukuba asondelelane.

Ekugqibeleni,izinto eziphathekayo kunye nezixhobo ezisetyenziswayo yimiba ebalulekileyo. Izixhobo ezahlukeneyo zisabela ngokwahlukileyo kubushushu kunye noxinzelelo, zifuna iimeko ezahlukeneyo zokucoca ngokufanelekileyo. Uhlobo lwesithando somlilo okanye umatshini we-sintering unokuchaphazela inkqubo, njengoko siza kuxubusha kwicandelo elilandelayo.

Hlala ubukele njengoko sijonga ngakumbi malunga noomatshini bokuntywila kunye nendima yabo kwinkqubo yokuntywila!

Izixhobo zeSintering: Ukujongwa koomatshini beSintering

Ukuza kuthi ga ngoku, besiwuphonononga ngokucokisekileyo ingqikelelo ye-sintering, imathiriyeli ye-sintered, kunye nenkqubo ngokwayo.

Ngoku makhe sikhanyise kumdlali ophambili osemva kwesigcawu:umatshini wokuhlamba.

Umatshini we-sintering usisiseko senkqubo ye-sintering. Kodwa yintoni kanye kanye umatshini wokuhlamba? Ngokusisiseko, sisithando somlilo esikhethekileyo esilungiselelwe ukwenza inkqubo yokuntywila phantsi kweemeko ezilawulwa ngononophelo.

Naziiintlobo ngeentlobo koomatshini sinteringekhoyo, nganye ifanele imathiriyeli ezahlukeneyo kunye neendlela zokucoca.

1. Ezi ziqukaOomatshini be-sintering abaqhubekayo(isetyenziswa kumashishini afuna imveliso ephezulu),

2.Oomatshini bokuhlamba ibhetshi(ixhaphake ngakumbi kwiilebhu okanye kwimveliso yomthamo ophantsi), kunye

3. Oomatshini bokucoca ivacuum(evumela ukuntywila kwindawo engenanto okanye elawulwayo).

Indlela umatshini we-sintering osebenza ngayo iqondile kodwa inomdla. Ifudumeza ngokulinganayo into engumgubo kwiqondo lobushushu elithile, igcine obu bushushu kangangexesha elimiselweyo, ize ke ipholise imathiriyeli ngokucothayo, lonke ixesha iqinisekisa ukuba umoya ongaphakathi uyalawuleka.

Ukukhetha umatshini wokuhlamba ofanelekileyo kubalulekile kwaye kuxhomekeke kwizinto ezininzi, kubandakanywa imathiriyeli emele ifakwe, i-output efunwayo, kunye neemeko ezithile zokucoca ezifunekayo.

Ukubaluleka kunye nekamva leSintering

Ngoku lixesha lokucingisisa ngomfanekiso omkhulu:Sintering isetyenziselwa ntoni, kwayekutheni ibalulekile?

Iizicelozomculo zinkulu kwaye zahlukahlukene. Isetyenziselwa ukwenza iimveliso ezixineneyo, ezomeleleyo ezinejometri ezintsonkothileyo, ukusuka kumacandelo emizimveliso ukuya kwimpahla yabathengi. I-Sintering ivumela ukuba sivelise izinto ezikumgangatho ophezulu, njengentsimbi edibeneyo kunye nezihluzo ezifakwe emanzini, ezineempawu ezizodwa ezifana nobukhulu bepore obulawulwayo kunye nokuphucula ukuqina.

Kodwaingaba ikamva lokucula lijongeka njani?Iindlela ezivelayo zibonisa ukwanda kokusetyenziswa kweendlela zokuxilisa ezincediswa ngoxinzelelo ekuveliseni izinto eziphambili. Ukuphuhliswa koomatshini abasebenzayo be-sintering kunye nokusetyenziswa kwe-sintering kwi-additive production (ukushicilela kwe-3D) zezinye iindlela ezithembisayo.

Ngaphandle kwezi nkqubela phambili, i-sintering ikwajongene nemingeni, efana nokufikelela kulawulo olukhulu kwinkqubo kunye nokunciphisa ukusetyenziswa kwamandla. Ukujongana nezi kuya kuba ngundoqo ekuvuleni amandla apheleleyo okucula kwixa elizayo.

Isiphelo:I-Sintering, ngelixa inkqubo enzima, ibamba impembelelo ebalulekileyo kumashishini ahlukeneyo. Ikhono layo lokuguqula i-powders elula ibe yinto eyomeleleyo, eyinkimbinkimbi yenza kube yinkqubo engabalulekanga. Njengoko sijonge phambili kwikamva, indaleko kunye nokucokiswa kwe-sintering kuthembisa amathuba anomdla kwimathiriyeli entsha kunye nezicelo.

FAQ

1. Yintoni inkqubo ye-sintering?

I-Sintering yinkqubo yonyango yokushisa eguqula izinto ezinomgubo zibe bunzima obuqinileyo ngaphandle kokunyibilika ngokupheleleyo. Kubandakanya ukufudumeza i-powder powder phantsi kwendawo yayo yokuncibilika de kube iinqununu ziqala ukunamathela omnye komnye, zenze ubunzima obuqinileyo. Le nkqubo isetyenziswa kumashishini ahlukeneyo afana nesinyithi, iiseramikhi, kunye nokuvelisa okongeziweyo ukuvelisa imathiriyeli exineneyo neyomeleleyo ukusuka kumgubo.

2. Kusebenza njani ukucula?

Inkqubo ye-sintering ibandakanya amanqanaba amathathu aphambili: ukufudumeza, ukubamba kunye nokupholisa. Isixhobo somgubo siqale sidityaniswe kwaye sibunjwe kwimilo efunekayo, emva koko ifudunyezwe kwindawo elawulwayo kwiqondo lobushushu elingaphantsi nje kwendawo yokunyibilika kwayo. Ubushushu bubangela ukuba amasuntswana adibane kunye, enze ubunzima obuqinileyo. Emva kokugcina eli qondo lobushushu kangangexesha elimiselweyo, loo nto iphinda ipholiswe kancinci ukunqanda ukuqhekeka okanye eminye imiba yesakhiwo.

3. Zeziphi izixhobo ezinokutshizwa?

Uluhlu olubanzi lwemathiriyeli inokutshizwa, kubandakanywa isinyithi, iiseramikhi, iiplastiki kunye neglasi. Izixhobo ezahlukeneyo zifuna iimeko ezahlukeneyo ze-sintering, ezifana nobushushu, uxinzelelo kunye nomoya. Ezinye izinto zinokufakwa ngokuthe ngqo kwi-sintered, ngelixa ezinye zifuna izongezo okanye izibophelelo ukuququzelela inkqubo.

4. Yintoni i-sintered filter, kwaye kutheni isetyenziswa?

Isihluzo se-sintered luhlobo lwesihluzo esiveliswa ngenkqubo yokucofa. Ingenziwa ngesinyithi, i-ceramic, okanye i-powders yeglasi, idityaniswe kwaye ifudunyezwe de amaqhekeza ahlangane kunye. Ubungakanani bepore yezi zihluzo zinokulawulwa ngokuchanekileyo, ukunika amandla okucoca aphezulu xa kuthelekiswa nezihluzo zemveli. Izihluzi ze-Sintered zomelele kakhulu kwaye ziyamelana nobushushu obuphezulu kunye noxinzelelo, zibenza babe luncedo kumashishini ahlukeneyo afana namayeza, iikhemikhali zepetroli, kunye nokuveliswa kokutya nesiselo.

5. I-sintering isetyenziswa njani kwimveliso yokongeza (ushicilelo lwe-3D)?

Kwimveliso eyongezelelweyo, okanye ukuprinta kwe-3D, i-sintering isetyenziswa kwiindlela ezifana ne-selective laser sintering (SLS) kunye ne-metal laser sintering (DMLS). Ezi ndlela zibandakanya ukusebenzisa i-laser ukwenza i-sinter yezinto ezinomgubo umaleko, ukwakha into efunwayo ye-3D. Ukukwazi ukulawula inkqubo ye-sintering ngokuchanekileyo kwenza kube lula ukuvelisa iimilo ezintsonkothileyo kunye neejometri eziya kuba nzima okanye zingenzeki ukufikelela ngeendlela zemveli zokuvelisa.

6. Lithini ikamva lokucula?

Ikamva le-sintering lijongeka lithembisa, kunye nenkqubela phambili yetekhnoloji evula amathuba amatsha. Umzekelo, ubuchule bokuntywila obuncediswa luxinzelelo buya buxhaphaka kakhulu ekuveliseni imathiriyeli ephezulu. Ukuphuhliswa koomatshini bokucoca abasebenzayo nabachanekileyo, kunye nokusetyenziswa kwe-sintering kwi-additive production, zezinye iindlela ezithembisayo. Nangona kunjalo, imiceli mngeni efana nokufikelela kulawulo olukhulu kwinkqubo kunye nokunciphisa ukusetyenziswa kwamandla kufuneka kuqwalaselwe ukuze kuvulwe ngokupheleleyo amandla okusebenzisa i-sintering.

Nokuba ujonge ukuphumeza iinkqubo ze-sintering kwimisebenzi yakho okanye ufuna izixhobo ezikumgangatho ophezulu we-sintered kwiiprojekthi zakho, i-HENGKO ilapha ukunceda. Iqela lethu leengcali limi lilungele ukunika iingcebiso, izisombululo, kunye neenkonzo ezilungiselelwe iimfuno zakho ezizodwa.

Ungalibazisi ukufikelela kuthi ukuze ufumane ulwazi oluthe kratya kwinkqubo enika umdla yokucula okanye ujonge uluhlu lwethu olubanzi lweemveliso kunye neenkonzo. Sithumele nje i-imeyile kuyoka@hengko.com, kwaye siza kunxibelelana kungekudala. sizimisele ukukunceda ujike amathuba omgubo abe yimpumelelo eqinileyo!

Thumela umyalezo wakho kuthi:

Ixesha lokuposa: Jul-03-2023