Iintsimbi zisetyenziswa ngokubanzi izinto kumashishini ahlukeneyo ukusuka kulwakhiwo ukuya kwimveliso. Nangona kunjalo, abantu abaninzi bayazibuza ukuba isinyithi sinamabhobhothi. Kweli nqaku, siza kuxubusha ukuba yintoni i-porosity, indlela echaphazela ngayo isinyithi, kwaye siphendule imibuzo ehlala ibuzwa malunga ne-porosity kwisinyithi.

Yintoni i-porosity?

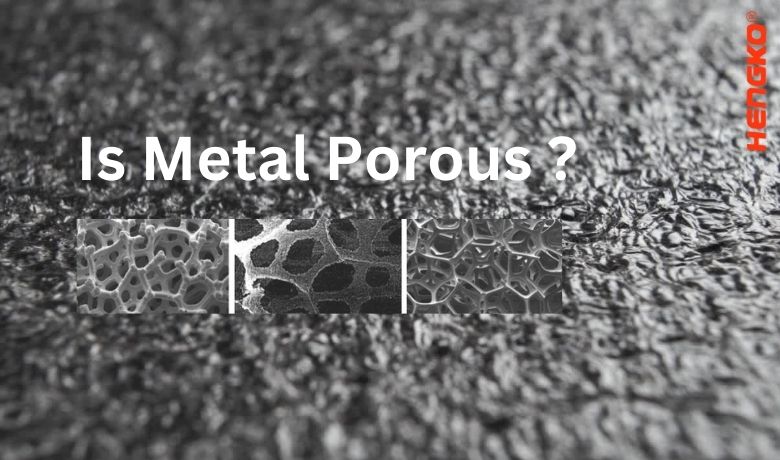

I-Porosity ngumlinganiselo wesithuba esingenanto (iipores) ngaphakathi kwesixhobo. Ngumlinganiselo womthamo wezi zithuba ezingenanto ukuya kumthamo opheleleyo wezinto eziphathekayo. I-Porosity ichaphazela iipropati ezibonakalayo kunye noomatshini bezinto ezifana nokuxinana, amandla kunye nokungena.

Kukho iintlobo ezahlukeneyo zePorosity, kuquka:

I-Porosity evaliweyo:I-Voids engaxhunywanga kumphezulu wezinto eziphathekayo.

Vula i-porosity:I-voids idityaniswe kumphezulu wesixhobo.

Ngokusebenzisa i-Porosity:I-voids idityaniswe kwimigangatho yomibini yemathiriyeli.

Eminye imizekelo yemathiriyeli enemingxuma zizipontshi, iphepha, kunye nogwebu, lo gama imathiriyeli engeyiyo i-porous ibandakanya iglasi, iiseramikhi, kunye nezinye isinyithi.

Ithetha ukuthini i-porous?

I-Porous sisichazi esichaza into ene-voids okanye i-pores evumela ulwelo okanye igesi ukuba idlule kuyo. Ngamanye amazwi, libhekisela kubuchule bento yokufunxa okanyevumela izinto ukuba zidlule. Izixhobo ze-Porous zinendawo ephezulu kwaye zisetyenziswa kwiintlobo ezahlukeneyo zezicelo ezifana nokuhluza, ukugquma kunye nokufunxa.

Imizekeliso yeMathiriyeli yePorous kunye neNon-Porous

1. Eminye imizekelo yeMathiriyeli enePorous zezi:

isipontshi

umhlaba

iinkuni

Ugwebu

Iphepha

amalahle

2. Eminye iMizekeliso yeMathiriyeli engenazibonda zezi:

Iglasi

iiseramikhi

Iintsimbi ezithile (ezifana negolide, isilivere, neplatinam)

iplastiki (kuxhomekeke kuhlobo)

I-Porosity kwiZinyithi

Izinyithi zinokuba ne-porous ngenxa yenkqubo yokuvelisa okanye ukusetyenziswa okujoliswe kuyo. Iintsimbi ezinamabhobhothi zinokuba neepropathi ezinjengokwanda kwendawo ephezulu, ukuhanjiswa kwe-thermal kunye nombane ophuculweyo, kunye nokuphuculwa kobuchule bokuhluza.

Ngokomzekelo, insimbi engenasici inokuba yi-porous ngenxa yobukho be-welds okanye ukubunjwa kwe-corrosion. I-Aluminiyam inokuba ne-porous ngenxa yokubunjwa kweengqimba ze-oxide okanye ukungcola kwintsimbi. Intsimbi isenokuba rhabaxa ngenxa yenkqubo yokwenziwa kwayo okanye ukuvezwa kwindawo ezonakalisayo.

Uvavanyo lwePorosity kwiiNsimbi

Ukumisela i-porosity yesinyithi, iindlela ezahlukeneyo zinokusetyenziswa, njenge:

Uhlalutyo lwe-metallographic:Oku kuquka ukusebenzisa imakroskopu ukuhlola ubume bentsimbi.

Iradiyografi:Oku kubandakanya ukuveza isinyithi kwi-X-reyi ukubona i-voids yangaphakathi.

Uvavanyo lwe-Ultrasonic:Oku kubandakanya ukusebenzisa amaza esandi aphezulu ukubona i-voids yangaphakathi.

Indlela yegesi yepycnometric:Oku kubandakanya ukulinganisa umthamo werhasi eshenxiswayo ngezinto eziqinileyo.

Indlela nganye ineenzuzo kunye nokungona kwayo kwaye inokukhethwa ngokweemfuno zesicelo.

IiPorous Metal Applications

Iintsimbi ezinamanzi zisetyenziswa kwiintlobo ngeentlobo zezicelo kuwo wonke amashishini, kubandakanya:

Iimoto:Isetyenziswa kwiinkqubo zokutofa kwamafutha, izihluzi zomoya kunye neenkqubo zokukhupha.

Ezonyango:Ukufakelwa, ukufakelwa kwamazinyo kunye nezixhobo zotyando.

I-Electronics:Kwiisinki zobushushu kunye nokukhusela i-electromagnetic.

I-Aerospace:Kwiitanki zamafutha, izitshintshi zobushushu kunye nezihluzi.

Ulwakhiwo:Kwiipaneli ze-acoustic kunye ne-facade cladding.

Ezinye zeemveliso zentsimbi ezandisiweyo kakhulu kwimarike ziquka isinyithi esandisiweyo sephepha,

ityhubhu yesinyithi eyandisiweyo, iphepha le-aluminiyam eyandisiweyo, iphepha le-aluminiyam eyandisiweyo, kunye ne-foam yentsimbi eyandisiweyo.

Indlela yokuthintela iipores kwiMetal

Imingxunya evuthuzayo inokuthintelwa ngokuthatha la manyathelo alandelayo:

Ukukhethwa ngokufanelekileyo kwezinto eziluhlaza kunye ne-alloys.

Ukulungiswa ngokufanelekileyo kweendawo zetsimbi ngaphambi kokudibanisa okanye ukudibanisa.

I-welding efanelekileyo okanye ubuchule bokudibanisa kunye neeparitha.

Sebenzisa igesi yokukhusela okanye i-flux.

Nciphisa ukuba sesichengeni kwimo engqongileyo eyonakalisayo.

Ngokuthatha la manyathelo, ukubunjwa kwe-voids kwintsimbi kunokuncitshiswa, kubangele iimveliso zetsimbi ezinamandla nezithembekileyo.

Ngaba iStainless Steel inePorous?

Intsimbi engatyiwa ngokuqhelekileyo ayijongwa njengesixhobo esinemingxuma ngokwengqiqo yemveli kuba ayivumeli izinto ukuba zidlule ngokulula. Nangona kunjalo, kubalulekile ukuba uqaphele ukuba iindawo zetsimbi ezingenasici zingatshintshwa ukuze zenze zibe zincinci okanye zincinci, kuxhomekeke kwinkqubo ethile yokugqiba esetyenzisiweyo. Umzekelo, umphezulu wentsimbi ecolisiweyo kakhulu awunabhonjana kunendawo ebrashiweyo okanye enesanti. Kwakhona, ukuba umphezulu wentsimbi engatyiwayo wonakele okanye uyakrwela, unokonakala lula kwaye unokuvumela izinto ukuba zingene lula.

Ngaba iAluminiyam iPorous?

I-aluminiyam ngokuqhelekileyo ithathwa njengesinyithi esinemingxuma kuba inokufunxa ngokulula ulwelo kunye neegesi ngomphezulu wayo. Oku kungenxa yokuba i-aluminiyam ngokwemvelo yenza umaleko obhityileyo we-oxide kumphezulu wayo, odala imingxunya emincinci apho izinto zinokudlula. Nangona kunjalo, idigri ye-porosity inokwahluka ngokuxhomekeke kwizinto ezifana ne-alloy ye-aluminium, ukugqitywa komphezulu, kunye naluphi na iingubo okanye unyango olufakwe phezulu. Kwezinye iimeko, i-aluminium inokuncitshiswa kwi-porosity ngokusebenzisa iinkqubo ezifana ne-anodizing okanye ukugqoka nge-sealant.

Ngaba iSteel inePorous?

Ngokufana nentsimbi engenasici, intsimbi ayijongwa njengesixhobo esinemingxuma ngokwesiqhelo. Nangona kunjalo, i-porosity yentsimbi inokuxhomekeka kwizinto ezininzi, ezifana nohlobo oluthile lwentsimbi, ukugqitywa komphezulu, kunye naluphi na iingubo okanye unyango olufakwe phezulu. Ngokomzekelo, iintlobo ezithile zetsimbi zinokuthi zibe nesakhiwo esiziinkozo ezivulekileyo kwaye zilungele ukubola okanye ukugqwala, oku kunokukhokelela ekubunjweni kweepores okanye i-cavities ngokuhamba kwexesha. Ukongezelela, ukuba umphezulu wentsimbi awucolwanga ngokufanelekileyo okanye ukhuselwe, unokuba ne-porous ngakumbi kwaye uchaphazeleke kwi-corrosion okanye ezinye iindlela zokuthotywa.

Zeziphi iiMveliso zeMetal ezidumileyo kwiMarike?

Ewe, kukho iimveliso ezininzi zentsimbi ezidumileyo kwimarike. Ezinye zezona mveliso zixhaphakileyo zentsimbi zezi:

5.1 I-Metal Plate eQiweyo

Ezi zintsimbi ezisicaba ezine-porosity elawulwayo ezingasetyenziselwa ukuhluza, ukusabalalisa kunye nezinye izicelo.

Ngokuqhelekileyo zenziwe ngensimbi engenasici, i-titanium okanye i-nickel alloys.

5.2 Ibhobho yeNsimbi enePorous

Ezi zityhubhu ezingenanto kunye ne-porosity elawulwayo engasetyenziselwa ukuhluza, ukukhupha umoya, kunye nezinye izicelo.

Ngokuqhelekileyo zenziwe ngensimbi engenasici okanye i-titanium.

5.3 Ipleyiti yeAluminiyam enePorous

Ezi zicwecwe ze-aluminium ezine-porosity ezilawulwayo ezingasetyenziselwa ukuhluza, ukusabalalisa kunye nezinye izicelo.

Ngokuqhelekileyo zisetyenziswa kumashishini afana ne-aerospace kunye neemoto.

5.4. Ipleyiti yeAluminiyam eQiweyo

Ezi zicwecwe ze-aluminium ezine-porosity ezilawulwayo ezingasetyenziselwa ukuhluza, ukusabalalisa kunye nezinye izicelo.

Ngokuqhelekileyo zisetyenziswa kumashishini afana ne-electronics kunye nezixhobo zonyango.

5.5 I-Porous Metal Foam

Ezi zizakhiwo ezikhaphukhaphu ezine-dimensional ezintathu ezenziwe ngeentsimbi ezine-porosity elawulwayo.

Ngokuqhelekileyo zisetyenziswa kumashishini afana namandla, i-aerospace kunye neemoto kwizicelo ezinje ngokutshintshiselana kobushushu,

abaguquli be-catalytic kunye nokufakwa kwesandi.

ukuququmbela

Isishwankathelo, isinyithi sinokuba neeporous ngenxa yezizathu ezahlukeneyo ezifana nenkqubo yokwenziwa kwesinyithi, ukuvezwa kwi-corrosion.

imeko-bume, okanye ukusetyenziswa okucetywayo. Iintsimbi ezinamaqhekeza zinezicelo ezininzi kumashishini ahlukeneyo kunye neempawu zabo zinokuba

iphuculwe ukuhlangabezana neemfuno ezithile. I-Porosity kwiintsimbi kufuneka ivavanywe ukuqinisekisa umgangatho kunye nokuthembeka kwayo. Ngokufanelekileyo

imilinganiselo, i-porosity kwiintsimbi inokuncitshiswa, okukhokelela kwiimveliso zetsimbi ezinamandla kunye nezizinzileyo.

Ixesha lokuposa: May-09-2023