Intshayelelo

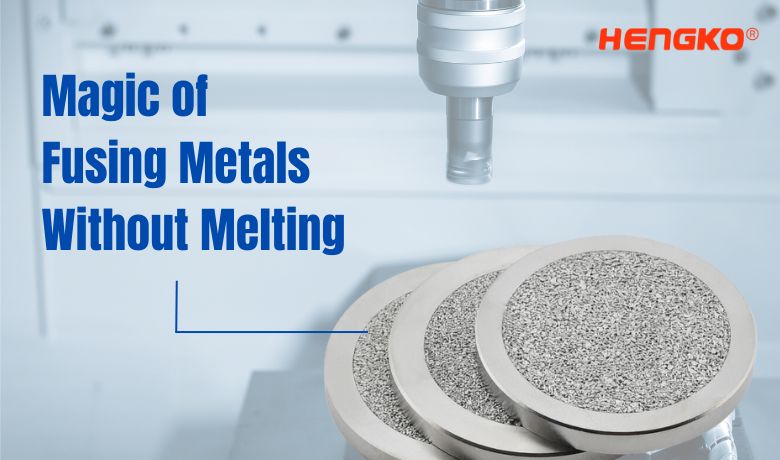

I-Sintering yinkqubo yenguqu edlala indima ebalulekileyo ekwenzeni amacandelo esinyithi asebenza kakhulu,

kuqukaizihluzi zetsimbi ezinamaqhekeza, isigqubuthelo sentsimbi engatyiwa sintered, isihluzi sokufunxa,izindlu zokufuma, ISO KF filter, Sparger njl.

Obu buchule bubandakanya ukudibanisa umgubo wentsimbi kunye nokuwafudumeza ngaphantsi kwendawo yokunyibilika,ukuvumela amasuntswana ukuba adibane

kwaye wenze isakhiwo esiqinileyo.Le ndlela ibalulekile ekudaleni amacandelo anengcaciso echanekileyo kunye nokwandiswa

iimpawu zoomatshini.

Umbuzo obalulekileyo ophakamayo:

Amasuntswana esinyithi anokudibana njani kwindawo enye eqinileyo ngaphandle kokunyibilika?

Impendulo ilele kwimigaqo ye-solid-state sintering, apho ukusasazwa kunye nohlengahlengiso lwamasuntswana lwenzeka.

kumaqondo obushushu aphakamileyo, okwenza ukwakheka kweebhondi eziqinileyo phakathi kwamasuntswana.

Ke masabelane ngeenkcukacha ezithe kratya kwaye sithethe ngayo yonke into malunga neSolid-State Sintering bellow.

Yintoni iSolid-State Sintering?

I-Solid-state sintering yinkqubo yokuvelisa esetyenziselwa ukwenza izinto eziqinileyo ezivela kumgubo wesinyithi ngokufaka ubushushu kunye noxinzelelo

ngaphandle kokuvumela izinto ukuba zinyibilike.

Le ndlela izahlula kwezinye iindlela zokuvelisa, ngakumbi ezo zibandakanya isinyithi esinyibilikisiweyo, njenge

ukuphosa okanye ukuwelda, apho izinto zitshintshela kwimeko yolwelo phambi kokuqina.

Kwi-solid-state sintering, amasuntswana esinyithi adityaniswa kunye kwaye aphantsi kobushushu obuphezulu, ngokuqhelekileyo ngaphantsi kokunyibilika.

indawo yentsimbi esisiseko.

Obu bushushu buququzelela ukusasazwa kweathom-ukuhamba kweeathom ngaphaya kwemida yamasuntswana akufutshane.

-bavumela ukuba benzebond kwaye wenze ubunzima obuqinileyo obudibeneyo.

Njengoko iqondo lokushisa linyuka, amasuntswana ahlengahlengisa kwaye akhule kunye, aphucula amandla kunye nokunyaniseka kwemveliso yokugqibela.

Isitixoumgaqongasemva eqinileyo-state sintering kukuba ukudityaniswa amasuntswana metal kwenzeka kumaqondo obushushu aphezulu ngaphandle

imfuneko yokuba zibe lulwelo.

Le ndlela ekhethekileyo yenza abavelisi bafezekise iipropati ezinqwenelekayo kumacandelo okugqibela ngelixa begcina i-dimensional

ukuchaneka kunye nokuthintela imiba efana nokushwabana okanye ukuphazamiseka okunokuthi kuvele ekunyibilikeni. Ngenxa yoko, i-solid-state sintering ibanzi

isetyenziswe kwizicelo apho ukusebenza okuphezulu kunye nokuchaneka kubalulekile, njengokuveliswa kwezihluzo zetsimbi ezinamaqabunga.

Indima yeqondo lobushushu kunye noxinzelelo kwiSolid-State Sintering

I-Solid-state sintering yinkqubo yokufudumeza amasuntswana esinyithi kwiqondo lobushushu elingaphantsi kwendawo yawo yokunyibilika, iwenze "thambile"

kunye nokwandisa ukuhamba kwazo kweathom. Oku kushukumiseka okuphuculweyo kweathom kubalulekile kwinkqubo yokuntywila, njengoko ivumela iiathom

ngaphakathi kweentsimbi zetsimbi ukuhamba ngokukhululekileyo.

Ngexesha le-solid-state sintering, uxinzelelo lusetyenziswa kumasuntswana esinyithi, ukuwasondeza kunye nokuququzelela ukusasazwa kwe-athomu.

Ukusasazwa kweathom yintshukumo yeeathom ngaphakathi kwesixhobo esiqinileyo, esivumela iiathom ezisuka kwelinye iqhekeza lesinyithi ukuba zifudukele kwizithuba.

phakathi kwamanye amasuntswana. Oku kuzaliswa kwezikhewu ngokusasazwa kweatom kubangela ukuba kuxinene kwaye kubambene ngakumbi.

Kubalulekile ukugxininisa ukuba kuyo yonke inkqubo ye-solid-state sintering, izinto zihlala ziqinile.

Amasuntswana esinyithi awanyibiliki;endaweni yoko, baba "thambileyo" ngokwaneleyo ukwenza ukusasazwa kweathomu, okukhokelela ekwakhekeni

yesakhiwo esixineneyo, esomeleleyo ngakumbi.

Ukusasazwa kweAtom: IMfihlo eNgemva kweNxubuwa yeNxulumano

Ukusasazwa kwe-atom ngumbono osisiseko kwi-solid-state sintering echaza intshukumo yeeathom ukusuka kwelinye isuntswana ukuya kwelinye, ngakumbi kwimida apho zidibana khona. Le nkqubo ibalulekile ekudityanisweni kwamasuntswana esinyithi ngaphandle kokunyibilika, okubavumela ukuba benze amabhondi aqinileyo, abambeneyo.

Xa iincinci zetsimbi zifudumala, ii-athomu zazo zifumana amandla, okwandisa ukuhamba kwazo. Kwiindawo zoqhagamshelwano phakathi kwamasuntswana amabini, ezinye iiathom zinokufuduka zisuka kwelinye ziye kwizithuba zomnye. Le ntshukumo ye-athomu yenzeke ngokuyinhloko kwiindawo kunye nemiphetho apho amasuntswana achukumisayo, edala ukudibanisa ngokuthe ngcembe kwezinto. Njengoko ii-athomu ezisuka kwelinye iqhekezana zisasazeka kwi-particle engummelwane, zigcwalisa i-voids, ngokudibanisa ngokufanelekileyo amaqhekeza amabini kunye.

Isiphumo sale ntlukwano ye-athomu kukubunjwa kwezibophelelo ezinamandla phakathi kweengqungquthela, ukuphucula iimpawu zemishini yezinto. Ekubeni le nkqubo yenzeke kumaqondo okushisa angaphantsi kwendawo yokuncibilika, ingqibelelo yesakhiwo sensimbi igcinwa, ikhusela imiba enokuthi ivele ekunyibilikeni, njengokuphazamiseka okanye utshintsho olungafunwayo lwesigaba.

Ngaba imida phakathi kweMetal Particles Iyaphela ngokwenene?

Omnye umbuzo oqhelekileyo malunga nenkqubo ye-sintering kukuba ngaba imida phakathi kweengqungquthela zetsimbi zanyamalala ngokupheleleyo. Impendulo i-nuanced: ngelixa iinqununu zidibanisa ngokuyinxenye ngexesha le-sintering, eminye imida inokuhlala ibonakala ngokuxhomekeke kwiqondo le-sintering kunye neemfuno ezithile zesicelo.

Ngexesha lenkqubo ye-sintering, njengoko ukusasazwa kwe-athomu kwenzeka, amaqhekeza asondelana kunye kwaye adibanise kwiindawo zabo zoqhagamshelwano. Olu nxulumano luphumela ekunciphiseni imida ebonakalayo, ukudala isakhiwo esidibeneyo. Nangona kunjalo, ukunyamalala okupheleleyo kwayo yonke imida akunakwenzeka, ngakumbi kwizicelo ezifana nezihluzo ezinabileyo, apho ukugcinwa kweqondo elithile le-porosity kubalulekile ekusebenzeni.

Kwizihluzi zetsimbi ezinamaqhekeza, umzekelo, umgangatho othile wokugcinwa komda wamasuntswana unenzuzo. Le mida inceda ukucacisa isakhiwo se-porous, sivumela iimpawu zokuhamba ezifunwayo ngelixa zinika amandla aneleyo. Ngokuxhomekeke kwiimeko ze-sintering-ezifana neqondo lokushisa, ixesha, kunye noxinzelelo olusetyenzisiweyo-eminye imida inokuhlala ihluke, iqinisekisa ukuba izinto eziphathekayo zigcina iimpawu zayo zokusebenza.

Ngokubanzi, ngelixa i-sintering ikhuthaza ukudibanisa okuqinileyo phakathi kwamaqhekeza kunye nokunciphisa ukubonakala kwemida, ubungakanani bokutshatyalaliswa kwayo buhluka ngokusekelwe kwisicelo esithile kunye neempawu ezifunwayo zemveliso yokugqibela. Olu lungelelwaniso phakathi kwamasuntswana okudibanisa kunye nokugcina iimpawu eziyimfuneko zolwakhiwo lubalulekile ekuphuculeni ukusebenza kakuhle kwizicelo ezahlukeneyo.

Kutheni i-Solid-State Sintering ilungile kwizihluzi zeMetal zeNsimbi

I-Solid-state sintering iluncedo ngakumbi ekudaleni izakhiwo zesinyithi ezinabileyo, iyenza ibe lolona khetho lufanelekileyo kwizicelo zokucoca. Iimpawu ezikhethekileyo zale nkqubo zivumela ulawulo oluchanekileyo kwiipropati eziphambili, kubandakanywa i-porosity, amandla, kunye nokuqina, okuyimfuneko ekusebenzeni okusebenzayo kwezihluzo zetsimbi zetsimbi.

1. Ulawulo phezu kwePorosity:

Enye yeenzuzo eziphambili ze-solid-state sintering kukukwazi ukulungisa i-porosity yemveliso yokugqibela. Ngokuhlengahlengisa izinto ezifana nobungakanani bamasuntswana, uxinzelelo lokuxinana, kunye nobushushu be-sintering, abavelisi banokwenza izihluzi ezinobungakanani obuthile bepore kunye nokuhanjiswa. Olu lungelelwaniso lubalulekile ekufezekiseni ukusebenza kakuhle kohluzo, ukuqinisekisa ukuba isihluzi sibamba ngokufanelekileyo ungcoliseko ngelixa sivumela umyinge wokuqukuqela ofunekayo.

2. Ukomelezwa kunye noKuhlala ixesha elide:

I-Sintering ayikhuthazi kuphela ukudibanisa phakathi kwamasuntswana kodwa iphinda ikhulise amandla omatshini apheleleyo wezinto eziphathekayo. Inkqubo idala isakhiwo esomeleleyo esinokumelana noxinzelelo kunye noxinzelelo olufunyenwe kwizicelo zokuhluzwa kwamashishini. Ngenxa yoko, izihluzi zetsimbi zetsimbi zibonisa ukuqina okukhethekileyo, zinciphisa umngcipheko wokuqhekeka okanye ukuguqulwa kwexesha, nakwimimandla enzima.

3. Ukumelana neMichiza:

Izinto ezisetyenziswa kwi-solid-state sintering, njengentsimbi engatyiwa kunye nezinye iialloys, zihlala zibonisa ukuxhathisa okugqwesileyo kweekhemikhali. Le propati ibaluleke kakhulu kwiinkqubo zokuhluza apho ukuvezwa kweekhemikhali ezinobundlobongela okanye izinto ezidliwayo zixhaphakile. Izihlungi zetsimbi ze-Sintered zigcina ingqibelelo kunye nokusebenza kwazo phantsi kweemeko ezinzima, ziqinisekisa ukusebenza okuhlala ixesha elide.

4. Umgangatho ongaguqukiyo kunye nokusebenza:

I-Solid-state sintering ibonelela ngeziphumo zokuvelisa ezingaguqukiyo neziphindaphindwayo. Ikhono lokulawula iiparitha zokucubungula zikhokelela kwiimveliso ezikumgangatho ophezulu kunye neempawu ezifanayo, ukunciphisa ukuhluka ekusebenzeni. Oku kuhambelana kubalulekile kwiindawo zoshishino apho ukuthembeka nokusebenza kakuhle kubaluleke kakhulu.

Ngamafutshane, i-slid-state sintering ilungile ekuveliseni izihluzi zentsimbi ezinabileyo ngenxa yokukwazi ukulawula ngokuchanekileyo i-porosity, ukomeleza amandla kunye nokuqina, ukuqinisekisa ukuxhathisa kweekhemikhali, kunye nokugcina umgangatho ongaguqukiyo. Ezi zibonelelo zenza izihluzi zetsimbi ezifakwe kwi-sintered zibe zikhetho ezikhethiweyo kuluhlu olubanzi lwezicelo zokuhluza kwimizi-mveliso, ukuhambisa ukusebenza okuphezulu kunye nokuthembeka.

Iingcamango ezingezizo eziQhelekileyo malunga nokuSintering: AyikokuNyibilika

I-Sintering ihlala ingaqondwa kakuhle, ngakumbi imbono ephosakeleyo yokuba amasuntswana esinyithi kufuneka anyibilike ukuze adibanise kunye. Ngokwenyani, i-sintering ngokusisiseko yinkqubo eqinileyo yelizwe exhomekeke ekubopheleleni kwinqanaba leathom, kwaye lo mahluko unefuthe elibalulekileyo kumashishini ahlukeneyo.

1. Uluvo olungelulo: Amacandelo esinyithi kufuneka anyibilike ukuze adibanise

Abantu abaninzi bakholelwa ukuba ukuze amasuntswana esinyithi adibane, kufuneka afikelele kwindawo yawo yokunyibilika. Nangona kunjalo, i-solid-state sintering kwenzeka kumaqondo obushushu angaphantsi kokunyibilika, apho amasuntswana esinyithi athi "thambile" kwaye avumele ukusasazwa kwe-athomu ngaphandle kokutshintshela kwimeko yolwelo. Le nkqubo ikhuthaza amabhondi aphakathi kwamasuntswana ngelixa igcina ingqibelelo eqinileyo yemathiriyeli, ebaluleke kakhulu kwizicelo ezifuna imilinganiselo echanekileyo kunye neempawu.

2. I-Advanteji ye-Solid-State Bonding

Ubume bemeko eqinileyo ye-sintering ibonelela ngeenzuzo ezininzi kwiinkqubo ezisekelwe ekunyibilikeni. Kuba akukho nqanaba lolwelo elibandakanyekayo, imiba efana nokushwabana, ukonakala, kunye notshintsho lwesigaba luyancitshiswa. Oku kuqinisekisa ukuba imveliso yokugqibela igcina imilo ekujoliswe kuyo kunye neempawu zoomatshini, nto leyo ibaluleke ngakumbi kumashishini afana ne-aerospace, i-automotive, kunye nokucoca.

3. IiPropati zoomatshini eziphuculweyo

Izixhobo ze-Sintered zihlala zibonisa iimpawu eziphezulu zemishini xa kuthelekiswa nezo zenziwe ngeenkqubo zokunyibilika. Iibhondi ezomeleleyo ezenziwe ngexesha le-sintering zikhokelela ekomelezeni okuphuculweyo, ukuxhathisa, kunye nokuqina. Oku kwenza amacandelo e-sintered alungele izicelo ezibango apho ukusebenza kunye nokuthembeka kubaluleke kakhulu.

4. I-Versatility kuwo wonke amaShishini

Iimpawu ezikhethekileyo ze-Sintering zenza ukuba ibe yindlela ekhethwayo kumashishini ahlukeneyo, ukusuka ekuveliseni izihluzi zetsimbi ezinabileyo zokucoca ngokufanelekileyo ukwenza izinto ezichanekileyo zombane kunye nezixhobo zonyango. Ikhono lokulawula i-porosity kunye nezinye iipropathi ngexesha le-sintering livumela abavelisi ukuba balungise iimveliso ukuhlangabezana neemfuno ezithile.

Ukuqukumbela, kubalulekile ukuqonda ukuba i-sintering ayikokunyibilika kodwa imalunga nokudala amaqhina aqinileyo, ahlala eqinile kwimeko eqinileyo. Oku kuqonda kugxininisa iingenelo ze-sintering ekuveliseni amacandelo akumgangatho ophezulu kuluhlu olubanzi lwamashishini, okwenza kube bubuchwepheshe obuphambili kwimveliso yanamhlanje.

Ukuqukumbela

Isishwankathelo, i-solid-state sintering yinkqubo ephawulekayo eyenza ukuba amasuntswana esinyithi adibane kunye ngaphandle kokunyibilika, kuxhomekeke kukusasazwa kwe-athomu ukwenza iibhondi ezomeleleyo. Le ndlela isebenza ngokukodwa ekuveliseni izihluzi zetsimbi ezinamaqhekeza, zinika ulawulo oluchanekileyo phezu kwe-porosity, amandla, kunye nokuqina. Iingenelo zamacandelo esinyithi esintered zibenza balungele usetyenziso olwahlukeneyo kumashishini amaninzi.

Ukuba ucinga ngezibonelelo zezinto zetsimbi ezifakwe kwiiprojekthi zakho, siyakumema ukuba ufikelele kwi-HENGKO ngengcebiso yeengcali.

Qhagamshelana nathi kuka@hengko.comukuxoxa iimfuno zakho OEM izisombululo sintered metal.

Ixesha lokuposa: Nov-02-2024