Insimbi engenasici yinto engakholelekiyo edlala indima ebalulekileyo kumashishini ahlukeneyo, ngenxa yeempawu zayo ezizodwa kunye nokusebenza okungenakuthelekiswa nanto. Kodwa ngaba ubusazi ukuba kukho imfihlo efihlakeleyo yokugcina ukusebenza kwayo kunye nobomi obude? Le mfihlelo ilele kwinkqubo eyaziwa ngokuba yipassivation.

Intshayelelo yeNsimbi eNgatyiwayo

Ukuqonda amandla e-passivation kuqala ngokuxabisa izinto ezisisiseko zensimbi engenasici ngokwayo. Intsimbi engatyiwayo ayiyonto nje elula;

yingxubevange eyenziwe ngentsimbi, ikhabhoni, kunye nethamo lesisa lechromium.

Yintoni eyenza iStainless Steel yahluke

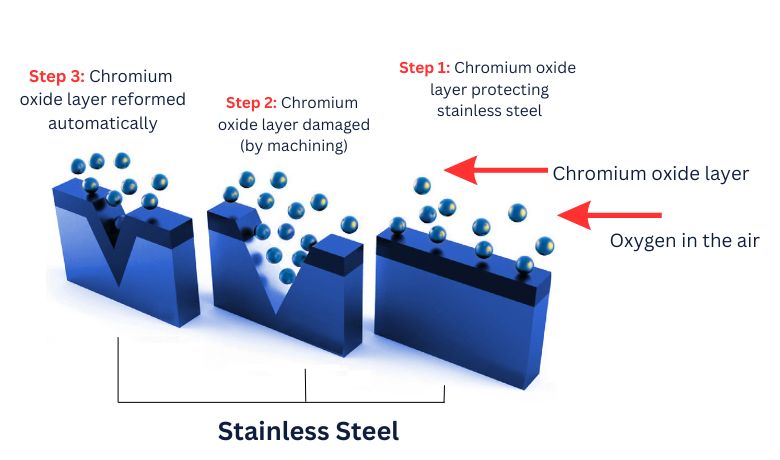

Umdlali ophambili kwibali lensimbi engenasici yichromium. Xa ifakwe kwioksijini, ichromium yenza umaleko obhityileyo, ongabonakaliyo wechromium

oxide kumphezulu wentsimbi. Lo maleko awukwenzi, nto leyo ethetha ukuba awusabeli nayo nantoni na eyenye.

1. Ukuqonda ukuNxhathisa kokuMhlwa

I-Chromium oxide yingelosi engumgcini wentsimbi engatyiwayo. Ikhusela umhlwa kunye nokubola, okuyimigibe eqhelekileyo kwezinye iintsimbi ezininzi.

Oku kuxhathisa umhlwa kunika intsimbi engatyiwayo igama layo kunye nokusetyenziswa kwayo ngokubanzi.

2. Indima yePassivation kwiNtsimbi eNgatyiwayo

Ngoku, makhe singene kwisihloko esiphambili - ulwazelelelo. I-Passivation yinkqubo yeekhemikhali ephucula umaleko wechromium oxide owenzeka ngokwendalo.

Oku kwenza intsimbi ikwazi ukumelana nomhlwa kunye nokuhlwa.

3. ISayensi eNgemva kweNtshukumo

Ngexesha lokudlula, insimbi engenasici iphathwa ngesisombululo esincinci se-asidi. Oku kususa intsimbi yasimahla kunye nezinye izinto ezingcolisayo kumphezulu,

enokuthi iphazamise ukubunjwa kwe-chromium oxide layer.

Ngaba ungathanda ukwazi ukuba kutheni intsimbi engenasici kufuneka idlule?

Ekuqaleni, kufuneka sazi ukuba yintoni intsingiselo yentsimbi engenasici? Ukugqithiswa kwensimbi engenasici kubhekiselele ekwenzeni umphezulu wensimbi engenasici uphendule kunye ne-agent ye-passivation ukwenza ifilimu ezinzileyo ye-passivation ekhusela i-substrate yensimbi engenasici ekuruseni. okubangelwa yi-oxidation kunye nokugqwala. Ukusebenza kokumelana nomhlwa kwensimbi engenasici kulungileyo. Nangona kunjalo, kwiindawo eziselunxwemeni okanye ekudibaneni ne-asidi kunye neekhemikhali ze-alkali, ii-ion zekloridi ezenziweyo zinokungena lula kwifilimu yokwenziwa yensimbi engenasici. Intsimbi engenastainless iya konakala kwaye igle ngokuhamba kwexesha. Ngoko ke, isinyithi esingenasici sidinga ukugqithiswa. Insimbi engenasiphene egqithisiweyo inokuphucula isiseko se-anti-rust sokuqala ngeminyaka eyi-3-8, ukunciphisa kakhulu ithuba lentsimbi yentsimbi.

HENGKO steel stainless sintered filter element inobungakanani bepore yomoya echanekileyo, ubungakanani bomngxunya ofanayo kunye nokuhanjiswa okufanayo; ukunyanzeliswa komoya okulungileyo, ukujikeleza okukhawulezayo, isiphumo esihle sokungena, ukusebenza kakuhle kokucoca; Ukumelana ne-corrosion elungileyo, ukumelana nobushushu obuphezulu, ukuxhathisa ukothuka kobushushu, izinto zensimbi ezingenasici zinokuba ngu-600 Ukusebenza kwiqondo lobushushu eliphezulu; ubude betyhubhu ecocekileyo yokucoca inokufikelela kwi-800mm, ubungakanani obukhulu besakhiwo sepleyiti yokucoca inokufikelela kwi-800mm ubude * 450mm ububanzi, kunye nobukhulu bobubanzi besakhiwo sokucoca esijikelezayo sinokufikelela kwi-450mm. Sikwabonelela nokunyanzeliswa kwamacandelo emveliso, Ukuba ufuna ukufaka isicelo kwi-corrosion engqongqo kunye nokuxhathisa umhlwa.

Iinzuzo zePasivation

Zininzi izibonelelo zokudlula intsimbi engatyiwayo, zonke ezinegalelo ekusebenzeni kwayo okuphuculweyo kunye nobomi obude.

Indlela yokwenza i-passivation-stainless steel?Masikuxelele.

Ngenxa yokuba iintlobo ezahlukeneyo zensimbi engenasici zisebenzisa imidibaniso eyahlukeneyo yeekhemikhali ze-passivation, ezinye iinkcukacha ziya kuhluka ngexesha lenkqubo yokupasa yensimbi engenasici. Passivation ifuna isiko. Nangona kunjalo, inkqubo esisiseko ihlala inamanyathelo afanayo: Qinisekisa ukuba umphezulu wenxalenye ucocekile. Kuphela xa i-substrate ibonakalisiwe inokugqithiswa ngcono. Beka enye okanye iindawo ezininzi eziza kugqithiselwa kwisikhongozeli. Galela ulwelo lwekhemikhali kwisikhongozeli kwaye uvumele iinxalenye zifunxe kangangexesha elithile. Hlamba ngamanzi abalekayo. Qinisekisa umphezulu wenxalenye ecociweyo kwaye ngaphandle kolwelo olushiyekileyo oluvuliweyo.

I-nitric acid passivationyenye yetekhnoloji yangoku yokupasa esisiseko. Ngaphambi kokukhetha iteknoloji ye-passivation, kufuneka sazi isisombululo sekhemikhali esifunekayo kwi-reaction passivation yensimbi engenasici ukuphepha ukusebenzisa isisombululo esingalunganga sokwenza umonakalo kwiindawo. Kwaye kwangaxeshanye ukhetha itekhnoloji ye-passivation ehambelanayo ngokweempawu zetsimbi engenanto. Umzekelo, umxholo wechromium we-austenitic stainless steel (efana ne-304 steel stainless) ihlala iphezulu kuneye-martensitic stainless steel (efana ne-430 stainless steel), okwenza i-alloys ye-austenitic imelane ngakumbi nokubola kunye nokugoba.

Ngaphambi kokugqithiswa kweengxenye zetsimbi, oku kulandelayo kufuneka kuqwalaselwe:

Iiweldments zisenokungalungeli ukupasa. Ifilimu ye-passive ebusweni bensimbi engenasici yenza i-corrosion resistant. I-arc welding iya kubeka izinto kwixesha elifutshane lokuhamba ngebhayisikile ye-thermal, ngaloo ndlela itshabalalisa ukuxhathisa kwayo.

Ibhafu yekhemikhali yesiko iyafuneka. Ubushushu kunye nohlobo lwe-asidi esetyenziswe kwinkqubo yokugqithisa kufuneka ilungiswe ngokuhambelana ne-alloy egqithisiweyo. Oku kongeza iindleko kunye nobunzima xa kuthelekiswa ne-electropolishing. Ezinye ii-alloys azikwazi ukugqithiswa. Ngokomzekelo, ezinye ii-alloys zensimbi ezingenasici ezine-chromium ephantsi kunye nomxholo we-nickel ziya kutshatyalaliswa. Ngoko ke, azinakuguqulwa.

Inzuzo ephambili ye-stainless steel passivation kukuba inokuphucula ukuxhathisa kwe-rust ye-stainless steel parts, kwaye iindleko ziphantsi kunezo ze-electropolishing. Eyona nto ingathandekiyo enkulu yenkqubo ye-electropolishing kukuba ibiza kakhulu kunenkqubo yokupasa esemgangathweni. Ukongezelela, i-electropolishing ayinayo impembelelo ebalulekileyo kwi-oxide ekhuselayo yensimbi efana ne-passivation.

Nangona kunjalo, xa uthetha ngobume bomphezulu wamalungu kuqwalaselo oluphambili, i-electropolishing iselunyango olukhethwayo. I-passivation ayifani ne-electropolishing ukwenza ubuso benxalenye bugudileyo, kwaye ayitshintshi kakhulu ukubonakala kwenxalenye. Ngoko ke, i-passivation ayiyona indlela efanelekileyo ukuba imveliso idinga indawo egudileyo kunye nengenakunqanda. Amashishini okutya kunye namayeza athanda ukusebenzisa i-electro-polished steel stainless surfaces kuba umphezulu ugudile kwaye kulula ukuwucoca kunye nokubulala iintsholongwane.

Ii-FAQs

1. Yintoni ulwazelelelo?

I-Passivation yinkqubo yeekhemikhali ephucula umaleko wechromium oxide owenzeka ngokwendalo

kwintsimbi engenastainless, ngaloo ndlela inyusa ukuxhathisa kwayo kumhlwa kunye nokudleka.

2. Isebenza njani i-passivation?

Ngexesha lokudlula, insimbi engenasici iphathwa ngesisombululo esincinci se-asidi sokususa

izinto ezingcolisa umphezulu. Iyacocwa yomiswe, kwaye ichromium idibana nomoya ukwenza umaleko omtsha, owomeleziweyo wechromium oxide.

3. Kutheni i-passivation ibalulekile kwintsimbi engenasici?

I-Passivation ibalulekile kwintsimbi engenasici njengoko inyusa ukuxhathisa kwe-corrosion, yandisa ubomi bayo,

kwaye igcina umdla wayo wobuhle.

4. Kufuneka kugqitywe kangaphi intsimbi engatyiwayo?

I-frequency of passivation ixhomekeke kwiimeko zokusebenza zensimbi engenasici. Kwi-corrosive ngakumbi

Imeko-bume okanye apho into iphathwa rhoqo, uvakaliso oluqhelekileyo lunokuba yimfuneko.

5. Ngaba i-passivation ichaphazela ukubonakala kwensimbi engenasici?

Ewe, ukunyamezela kunceda ukugcina imenyezelayo, inkangeleko ecocekileyo yentsimbi engatyiwayo ngokuthintela umhlwa nomhlwa.

6. Ngaba zonke izinto zensimbi ezingenasici zinokugqithiswa?

Ewe, zonke izinto zensimbi ezingenasici zinokugqithiswa. Nangona kunjalo, imfuno yokupasa iya kuxhomekeka kwi

iimeko zokusebenza zento.

7. Ngaba ukunyanzeliswa yinkqubo ebiza imali eninzi?

Ngelixa kukho iindleko ezibandakanyekayo kwi-passivation, ngokuqhelekileyo ithathwa njengeendleko ezifanelekileyo xa kukhuselwe

ibonelela kwintsimbi engenasici kunye nokwandiswa kwesiphumo sobomi bayo.

8. Kwenzeka ntoni ukuba intsimbi engatyiwayo ayisetyenziswa?

Ukuba intsimbi estainless ayidluliswanga, inokuba sesichengeni sokubola, nto leyo enokubangela ukuba kubekho ixesha elifutshane.

ixesha lokuphila kunye nokuncipha komtsalane wobuhle.

9. Ngaba i-passivation yenza intsimbi engatyiwayo yomelele?

I-passivation ayifuni ukwenza intsimbi engatyiwayo yomelele. Iphucula ukomelela kwayo ngokomeleza ukuxhathisa kwayo ekudlekeni.

10. Ndingakwazi ukwenza i-passivation ekhaya?

Ukupasa kufuneka kwenziwe ngabaqeqeshi abaqeqeshiweyo ukuqinisekisa ukuba inkqubo iqhutywa ngokuchanekileyo nangokukhuselekileyo.

Ngaba ufuna iinkcukacha ezingakumbi? Silapha ukuze Sincede!

Ukuqonda ubucukubhede bentsimbi ye-sintered stainless kunye nenkqubo yokugqithisa kunokuba nzima.

Ukuba unomdla wokuphucula ukusebenza kunye nobomi bezinto zakho zentsimbi engenasici okanye ukukhangela eyona ilungileyo

Isihluzi esikhethekileyo se-OEM esinentsimbi esikhethekileyo senkqubo yakho yokuhluza, iqela lethu lilapha ukukukhokela.

Xhumana nathi eHENGKO, kwaye masivule amandla apheleleyo eenkqubo zakho kunye. Finyelela kuthi nge-imeyile

at ka@hengko.com, kwaye iqela lethu elinolwazi liya konwaba ngakumbi ukukunceda ngemibuzo yakho.

Indlela yakho eya kwisistim yokucoca ephuculweyo yi-imeyile nje kude. Musa ukulinda. Qhagamshelana nathi namhlanje!

Ixesha lokuposa: Oct-10-2020