Yintoni iSintered Metal ?

Yintoni uMgaqo wokuSebenza weSintered Filter?

Ngamafutshane ukutsho, Ngenxa yefreyimu yeporous ezinzileyo,izihluzi zetsimbi zentsimbiyenye yezinto ezingcono zokuhluza

kule mihla. Kwakhona, ubushushu obuphezulu bezinto zentsimbi, uxinzelelo oluphezulu, kunye nokumelana nomhlwa kunokukunceda

gqibezela ngokulula umsebenzi wokucoca kwindawo engqongqo, Ukwahlula kunye nokuhluza ukungcola okugqithisileyo

awudingi okanye akuncedi ukuba ukhuphe iigesi zococeko eziphezulu okanye ulwelo lweprojekthi yakho, kwaye ukuba ujonge

omnye umzi-mveliso wokwenyani ukuya OEM sintered isihluzo sentsimbi kwinkqubo yakho yokuhluza, nceda ujonge apha ukufumana

iAbavelisi beZihluzo zoShishino eziphezulu.

Mhlawumbi Akufunekanga uve eli gama kakhulu kubomi bakho bemihla ngemihla.

Kodwa kule mihla, isinyithi esidityanisiweyo sokusebenzisa ngakumbi nangakumbi kumashishini ahlukeneyo, intsimbi etshisiweyo sele iqalile

iitekhnoloji engundoqo kwimveliso ethile.

Emva kokoYintoni kanye kanye Sintered Metal?

Ngokwenyani, lisebe loshishino lwesinyithi somgubo, ngokufutshane, yintsimbi engatyiwayo engama-316L.umgubo ngokusebenzisa isikhunta

ukubunjwa, ubushushu obuphezulu bungena kubume kunye nomsebenzi wenkqubo esiyidingayo.

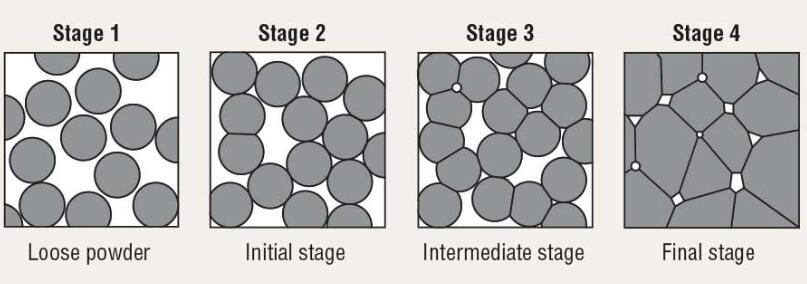

Emva koko, Okokuqala, wahleka.Yintoni i-sintered?

I-Sintering yinkqubo yokudibanisakunye nokwenza ubunzima obuqinileyo beimpahla

ngobushushu okanye ngoxinzelelo ngaphandle kokuyinyibilikisa ukuya kutsho kwinqanaba lokunyibilika. Sintering yinxalenyeinkqubo yokuvelisa esetyenziswayo

ngesinyithi, i-ceramics,iiplastiki kunye nezinye izinto.Wikipedia

Njengoko i-Wikipedia ichaza, iintlobo ezininzi zemathiriyeli zinokutshizwa, kunye nezixhobo ezahlukeneyo ezenziwe ngeemveliso

ezahlukeneyoizicelo. Emva koko apha siyathandaukuthetha iinkcukacha ezingaphezulu malunga sintered metal.

1. Ukuhluzwa kunye nokwahlula 2. Izithintelo zolwelo

3. Ukunciphisa ingxolo 4. Ukuhamba okuzinzileyo

ImbaliyeSintering Metal

Ngubani owasungula i-sintering kwaye waqala ukusebenzisa iimveliso ezifakiweyo?

Ngokweerekhodi zembali, inkqubo ye-sintering yavela ngexesha lesibini revolution yezoshishino ngenkulungwane ye-18

eSweden naseDenmark. Intsimbi enyibilikisiweyo yafunyanwa ngexesha lokunyibilikisa kwimigodi yamalahle. Kodwa kude kube ngo-1980, abantu

waqala ukusebenzisa intsimbi etshisiweyo kwioli yokucoca. Kwaye kwi-1985, eyokuqala yasebenzisa iteknoloji yokucoca i-HyPulse®

ukuhluzwa rhoqo kweoli eludaka.

Ke eneneni, ungajonga njengokulandelayo, kukho ixesha eliphambili lokuphuhlisa i-3.

Ke eneneni, ungajonga njengokulandelayo, kukho ixesha eliphambili lokuphuhlisa i-3.

1.Imvelaphi yamandulo

*Ubudala beBronze:

Ubungqina bokuqala beenkqubo ezifana ne-sintering zibuyela kwiBronze Age, apho izinto zentsimbi zazikhona

enokuba yenziwe ngokufudumeza kunye nokucinezela umgubo wesinyithi.

*Ubudala be-Iron:

Ubuchule bokusebenza kwentsimbi, kubandakanywa nokusetyenziswa kwentsimbi ekrwada efudunyeziweyo necinezelweyo, isenokuba ibandakanyiwe

izinto sintering.

2.Uguquko lwamaShishini kunye noPhuhliso lwakwaQala

* Inkulungwane ye-19:

I-Industrial Revolution yabona umdla owandisiweyo kubuchule bokusebenza kwesinyithi. I-metallurgy yomgubo,

i-precursor kwi-sintering, yaqala ukuvela njengendlela yokuvelisa izinto zetsimbi ezivela kwizinto ezinomgubo.

* Ekuqaleni kwenkulungwane yama-20:

Inkqubela phambili kwi-metallurgy kunye nesayensi yemathiriyeli ikhokelele kuphuhliso olungakumbi kubuchule bokuntywila.

Ukuveliswa kwezihluzo zetsimbi kunye neebheringi usebenzisa iinkqubo ze-sintering zaba yinto eqhelekileyo.

I-3.Ixesha langoku kunye neNkcubeko yeTekhnoloji

* Phakathi kwinkulungwane yama-20:

Itekhnoloji yeSintering yafumana ukukhula okubonakalayo phakathi kwenkulungwane yama-20, iqhutywa luphuhliso

kwiMetallurgy yomgubo kunye nesayensi yezixhobo. Ukuphuhliswa kwezixhobo eziphezulu ze-sintered ze

I-aerospace, i-automotive, kunye nezicelo zemizi-mveliso ziye zaba yinto ekugxilwe kuyo.

* Ngasekupheleni kwe20 kunye nasekuqaleni kwe21st Century:

Ngasekupheleni kwenkulungwane yama-20 kunye nasekuqaleni kwenkulungwane yama-21 kwabona ubungqina obuqhubekayo beteknoloji ye-sintering. Uphuhliso

Ubuchule obuphambili bokuntywila, obufana ne-selective laser sintering (SLS) kunye ne-binder jetting, yandisa uluhlu.

wemathiriyeli kunye neemilo ezintsonkothileyo ezinokuveliswa.

Izicelo zangoku

*Iimoto:

Izixhobo zeSintered zisetyenziswa ngokubanzi kumacandelo eemoto, kubandakanya iigiya, iibheringi kunye nezihluzi.

Iipropathi zabo, ezinje ngokuqina, ukuqina, kunye ne-porosity, zibenza balungele izicelo eziyimfuneko.

*Isiphekepheke:

Izinto ezifakwe kwi-Sintered zisetyenziselwa amacandelo e-aerospace ngenxa yobunzima babo, iipropati eziphakamileyo.

Zifumaneka kwiindawo ezinje ngee blade ze turbine, imilomo yamafutha, kunye nezitshintshisi zobushushu.

*Izixhobo zonyango:

Izinto ze-Sintered zisetyenziswa kwiintlobo ngeentlobo zezixhobo zonyango, kubandakanywa ukufakelwa, i-prosthetics, kunye namalungu amazinyo.

I-biocompatibility yabo kunye neempawu ezinokwenziwa ngokwezifiso zibenza bafanelekele ezi zicelo.

*Usetyenziso lwemizi-mveliso:

Izixhobo ze-Sintered zinezicelo ezininzi zemizi-mveliso, kubandakanya ukuhluza, i-elektroniki, kunye nokugcinwa kwamandla.

Ukuguquguquka kwabo kunye neempawu zokusebenza kubenza baxabiseke kuluhlu olubanzi lwamashishini.

Ukuqukumbela

Ngapha koko, itekhnoloji yeSintering iye yavela kakhulu kwiinkulungwane, ukusuka kwimvelaphi yayo yakudala ukuya kwizicelo zayo zanamhlanje.

Ngenkqubela phambili eqhubekayo kwinzululwazi yemathiriyeli kunye neenkqubo zokuvelisa, imathiriyeli e-sintered iye yaba

amacandelo abalulekileyo kumashishini ahlukeneyo, anegalelo kwinkqubela phambili yobuchwepheshe kunye nokusungula izinto ezintsha.

Ke yintoni iSintered Metal Filter?

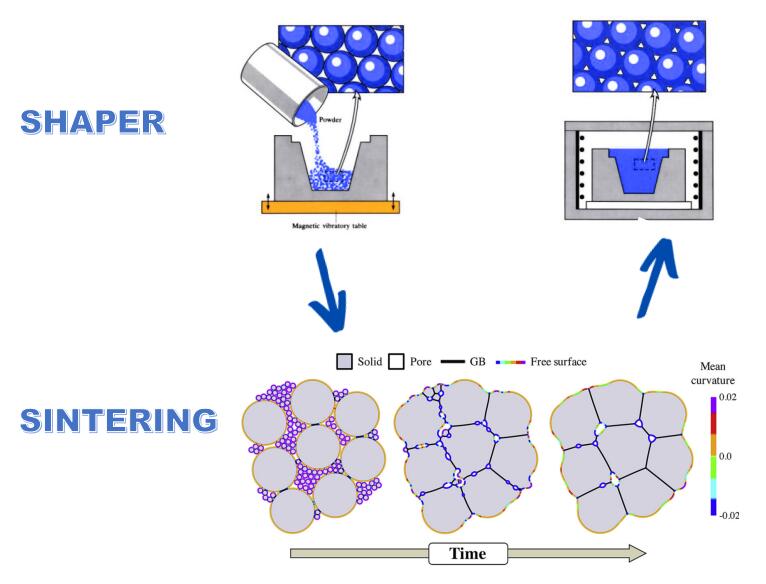

Ingcaciso elula yesihluzo sesinyithi esisikiweyo:

Sisihluzo sesinyithi esisebenzisa amasuntswana omgubo wesinyithi afanayoubungakanani besuntswanaukubunjwa ngesitampu,

inkqubo sintering lobushushu eliphezulu. Sintering yinkqubo yei-metallurgy kusetyenziswa umgubo wobungakananiimizimba ye

iintsimbi ezahlukeneyo kunye nengxubevange emva isitampu.

I-Metallurgy yenzeka ngokusasazwa kumaqondo obushushu angaphantsi kwendawo yokunyibilika yeziko lobushushu obuphezulu.

Iintsimbi kunye nealloysesetyenziswa ngokuqhelekileyo namhlanjezibandakanya i-aluminiyam, ubhedu, i-nickel, ubhedu, insimbi engenasici,

kunye ne-titanium.

Kukho iinkqubo ezahlukeneyo ongazisebenzisa ukwenza umgubo. Ziquka ukugaya, i-atomization,

kunye nokubola kweekhemikhali.

Yintoni iSintering Inkqubo yokuVelisa isihluzi sesinyithi

Ke, ke apha, sithanda ukujonga iinkcukacha zenkqubo yokwenziwa kohluzo lwesinyithi. ukuba unomdla, nceda ujonge ngezantsi:

1.) Yintoni iSintering, Kutheni usebenzisa iSintering?

Inkcazo elula ye-sintering ngumgubo wesinyithi udityaniswa kunye nobushushu obuphezulu kunye nezinye iindlela zibe

imodyuli efunwayo.Kuluhlu lwe-micron, akukho mda womzimba phakathi kwamasuntswana omgubo wesinyithi,

yiyo loo nto singakwazi ukulawula umgama we pore

ngenkqubo yemveliso.

I-cartridge ye-porous yenkqubo ye-sintering inikezela ubume obuzinzile besinyithi kwaye ibonelela

izinto kunye neukusebenza kokucoca okuqinileyo.

2.)3-EngundoqoAmanyathelo eSintered Metal Filter Manufacturing

A: Inyathelo lokuqala kukufumana i-Power Metal.

Umgubo wesinyithi, Ungafumana umgubo wesinyithi ngokusila, i-atomization, okanye ukubola kweekhemikhali.

Unokudibanisa isinyithi enyeumgubo kunye nenye isinyithi ukwenza i-alloy ngexesha lenkqubo yokwenziwa,

okanye ungasebenzisa umgubo omnye kuphela. I-advanteji yokucula yileyoayiwutshintshi umzimba

iimpawu zezinto zetsimbi. Inkqubo ilula kangangokuba izinto zetsimbi azitshintshwa.

B: Isitampu

Isinyathelo sesibini kukuthululela i-powder yensimbi kwi-mold elungiselelwe ngaphambili apho unokubumba khona isihluzo.

Indibano yokucoca yenziwe kwigumbiiqondo lobushushu naphantsi kwesitampu. Ubungakanani boxinzelelo olusetyenzisiweyo

kuxhomekeke kwintsimbi oyisebenzisayo, njengoko iintsimbi ezahlukeneyo zine-elasticity eyahlukileyo.

Emva kwempembelelo yoxinzelelo oluphezulu, i-powder yensimbi ihlanganiswe kwi-mold ukwenza isihluzo esiqinileyo.Emva kwe

inkqubo yempembelelo yoxinzelelo oluphezulu, unakobeka isihluzo sesinyithi esilungisiweyo kwiziko lobushushu obuphezulu.

C: Ubushushu obuphezulu beSintering

Kwinkqubo ye-sintering, iinqununu zetsimbi zixutywe ukuze zenze iyunithi enye ngaphandle kokufikelela kwindawo yokunyibilika.

Le monolith yomelele,eqinile, kunye ne-porous isihluzo njengesinyithi.

Ungalawula i-porosity yesihluzo ngenkqubo ngokwenqanaba lokuhamba komoya okanye ulwelo oluza kuhluzwa.

Ubume bomgangatho wemidiya edityanisiweyo ilingana nepore ephakathi, okanye i-avareji yobungakanani bepore yesihluzi.

Sintered metal media arezifundiswa kumabakala 0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 40 no-100.

ulwelo kumajelo eendaba amabakala 0.2 ukuya 20 luphakathi kwe-1.4 nama-35 µmngokupheleleyo. Iqondo lokuhluza kuluhlu lwegesi

ukusuka ku-0.1 ukuya kwi-100 µm ngokupheleleyo.

Kutheni kufuneka usebenzise iMetal Sintering ukwenza isihluzo?

Lo ngumbuzo olungileyo, kutheni usebenzisa isinyithi ukwenza isihluzo?

Impendulo ilula, kwaye nangona kukho izizathu ezininzi, iindleko zezona zibalulekileyo.

Kutheni iindleko ?

Ewe, intsimbi etshisiweyo inesakhiwo esizinzileyo kwaye inokuphinda isetyenziswe, icoceke kwaye isetyenziswe ngamaxesha amaninzi.

Kwaye kwakhona, iintsimbi ezahlukeneyo zineempawu ezizinzileyo zomzimba kunye neekhemikhali kwaye azonakaliswa lula.

Yiyo loo nto uninzi lweeFiltered Sintered zisetyenziswa kumashishini ahlukeneyo.

Yintoni Ukhetho Lwezinto eziphathekayoIzihluzi zeSintered?

Ngenkqubela phambili eqhubekayo yetekhnoloji yomgubo wesinyithi, kukho ukhetho oluninzi

izixhobo zokucoca isinyithi esine-sintered,

Unokukhetha kwezinye iintsimbi ezininzi kunye nealloys ukuhlangabezana neemfuno ezikhethekileyo eziphezulu

ubushushu kunye noxinzelelo, ukubolaukumelana etc , Izinto eziphambili zetsimbi ezifana :

-

Isihluzo seNsimbi eNgatyiwayo; 316L, 304L, 310, 347 kunye ne-430

-

Ubhedu

-

I-Inconel® 600, 625 kunye ne-690

-

I-Nickel200 kunye ne-Monel® 400 (70 Ni-30 Cu)

-

I-Titanium

-

Ingxubevange

Sinteredizihluzi zensimbi ezingenasici, kubandakanywa iikhatriji zokucoca, iipleyiti, kunye neetyhubhu ezenziwe ngensimbi engenasici

304 kunye ne-316, zibonelela ngokusulungekileyo okuphezulu, ubomi benkonzo ende, kunye nokuguquguquka kwizicelo zazo zombini ulwelo.

kunye nokuhluzwa kwegesi. Ziqhuba kakuhle kwiindawo ezinobushushu obuphezulu kunye neendawo ezingcolisayo.

Kuya kusetyenziswa isinyithi ngakumbi nangakumbi kwixesha elizayo.

8-Izinto eziluncedo eziphambili zeSintered Metal Filter

1. ) Ukumelana nokubola

Uninzi lwesinyithi luyakwazi ukumelana nokubola, njenge-sulfides, i-hydrides, i-oxidation, njl.

2. ) Ukususwa okusebenzayo ngakumbi kokungcola

Ukulungelelanisa i-porosity ye-cartridge kwi-fluid kuthetha ukuba unokufezekisa okugqibeleleyo

ukuhluzwa okufunayo kwaye ufumane iulwelo olungangcolisi. Kwakhona, ekubeni isihluzi singonakalisi,

impendulo yesihluzi ayiphumeleli kubukhozongcoliseko kulwelo.

3. ) Umothuko oPhezulu weThermal

Ngexesha lenkqubo yokuvelisa, ukushisa okuphezulu kuveliswa, kunye neempawu ezibonakalayo ze

ezi ntsimbi zinceda ukufunxaUmothuko omkhulu wesihluzi. Ngenxa yoko, ungasebenzisa ezi zinto

izihluzi kuluhlu olubanzi lwezicelo ngokuxhomekekeUluhlu lwe-thermal yesicelo.

Umothuko omkhulu we-thermal ikwaqinisekisa ukuhluzwa okusebenzayo kolwelo ngaphandle kokukhathazeka

ubushushu besicelo.

4,) Uxinzelelo olufanelekileyo lwehla

Aisihluzo sesinyithi esine-sinteredunokugcina uxinzelelo lolwelo kwisicelo sakho, ngaloo ndlela uqinisekisa

ukusebenza okuphezulu.

Ukuhla kancinci koxinzelelo kunokwenzakalisa isicelo sakho.

5. ) Ubushushu kunye nokuchasana noxinzelelo

Ungasebenzisa esi sihluzo kwizicelo ezinobushushu obuphezulu kunye noxinzelelo ngaphandle

ixhala malunga nesihluzo sakho.

Ukusebenzisa izihluzi zetsimbi zetsimbi kwinkqubo yokuveliswa kweekhemikhali kunye negesi

izityalo zonyango ziqinisekisa wenafumana ezona ziphumo zintle zokuhluza.

6. ) Unzima kwaye uxhathisa ukuphuka

Olunye uncedo lokusebenzisa i-sintered metal filter kukuba yomelele kwaye iyamelana nayo

ukwaphuka.

Ngethuba lokwenziwa kwenkqubo yokuvelisa, ukudibanisa kwesinyithi kwenzeka kumaqondo okushisa kakuhle

ngaphantsi kwendawo yokunyibilika.

Imveliso yesiphumo sisihluzo esiqinileyo sentsimbi esinokumelana nezinto ezahlukeneyo

iindawo ezinzima.

Umzekelo, ungayisebenzisa kwizicelo ezifuna ukungqubana ngaphandle koloyiko lokwaphuka.

7.) Ukunyamezela okulungileyo

Ukunyamezelana okucokisekileyo kuthetha ukuba isihluzo sakho sesinyithi esisinyibilikisiweyo sinokuhluza ulwelo lwakho ngaphandle kokusabela.

Nje ukuba ukuhluza kwakho kugqityiwe, isihluzo sesinyithi esisinyibilikisiweyo siya kugcina iimpawu zayo zomzimba.

Nangona kunjalo, kuya kunceda ukuba uqiniseke ukuba intsimbi oyikhethayo kwisihluzo sakho ayiyi

sabela ngolwelo oluhluzayo

8.) Uluhlu olunokwenzeka lweJometri

Iikhatriji ze-Sintered zikuvumela ukuba ujabulele uluhlu olubanzi lweenketho zejometri. Unako ukufezekisa

oku ngelixa ufaka umgubokwidayi ngexesha lokuvelisa.

Umngundo nguye omele ukuyila isihluzo sakho.

Ke ngoko, ukhululekile ukusebenzisa uyilo ngokweenkcukacha zakho.

Umzekelo, ukuba isicelo sakho sifuna isihluzo esincinci, ungalawula uyilo ngokulula

ukufumana encinci

isihluzo sesinyithi esine-sintered.Ngokukwanjalo, ukuba isicelo sakho sinoyilo olwahlukileyo, unokulula

lawula uyilo kwiisikhunta ngexesha lokuvelisa.

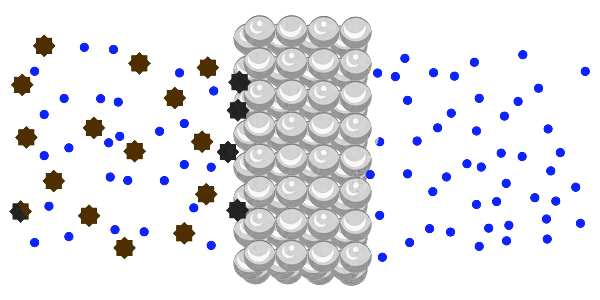

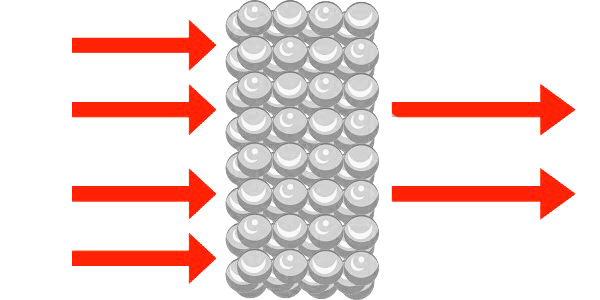

Zisebenza njani izihluzi zetsimbi zeSintered?

Le ngxaki inokuthiwa ngumgaqo wokusebenza we-sintered metal filters. Abantu abaninzi bayacinga

ukuba lo mbuzokunzima kakhulu ukuphendula, kwaye akunjalo.Unokumangaliswa koku, kodwa mhlawumbi wena

Andiyi kuba emva kokufunda ingcaciso yam.

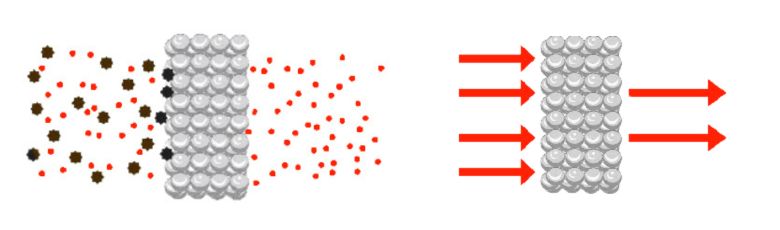

Izihluzo zetsimbi zetsimbi ziluncedo kakhulu kwizihluzi. Ukuqokelelwa kongcoliseko kwenzeka kumphezulu we

ulwelo; xa iulwelo ludlula kwisihluzo sesinyithi, iamasuntswana amakhulu kunye nezingcolisi ziya kuba

ekhohlo kwelinye icala ikhatriji, kodwa xaukukhetha inqanaba lokucoca elisebenzayo kulwelo lwakho, wena

kufuneka uqinisekise ukubainokucoca iimfuno.

*Ezi Mfuno zibandakanya

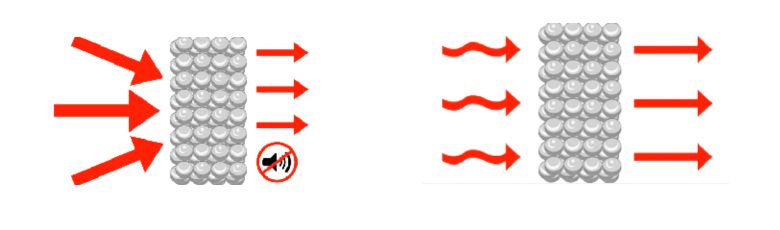

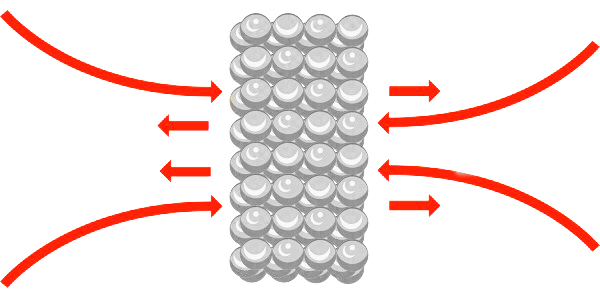

1. UkuGcina ukuGcina i-Backwash yekhono

2. Ukuhla koxinzelelo

Ukunciphisa uxinzelelo, kufuneka uqwalasele izinto ezininzi.

Ezi zinto ziquka

AI-viscosity yolwelo, isantya solwelo njengoko iqukuqela kwindawo yokucoca, kunye neempawu ezingcolisayo.

BIimpawu ezingcolisayo ziquka ukumila kwamasuntswana, ukuxinana, kunye nobukhulu.

Ukuba ungcoliseko lunzima kwaye luhlala lumile, lwakha ikhekhe elishinyeneyo, ngoko ke ukuhluzwa komphezulu kufanelekile.

*Ukusebenza kweSintered Metal Filtration kuxhomekeke kwi

1.ukunyuka koxinzelelo lwehla ukuya kwindawo apho uxinzelelo olupheleleyo lufikelela khona.

2. ukuhamba rhoqo kolwelo.

Unokufezekisa iimeko zokugqibela ngokunyusa ukungcola okunyuka ukuya kwindawo apho uxinzelelo lwe-fluid luhla.

Olu xinzelelo lwehla ngokuqhubekayo de kufike ukuhla okuphezulu kwe-viscosity enikiweyo kunye nemfuno yezinga lokuhamba.

Omnye umba obalulekileyo kukuhlanjwa ngasemva kwesihluzi, esenziwa ngokucinezela igesi kwiscreen kwaye ngokukhawuleza.

ukuvula ivalve yokukhupha umvanjengoko i-backwash isenzeka.

Umahluko woxinzelelo oluphezulu oluguqukayo olukhawulezileyoyenziwe. Isusa ngokufanelekileyo ukungcola kwisihluzi

umphezulu wento. Umvaukuhamba kolwelo olucocekileyo ngesixhobo sokucoca kususa izinto ezingcolisayo kwaye ziqondise

ngaphandle kwesihluzo.

Ukunyuka okuthe gqolo kwinqanaba lokuhla kwengcinezelo kubonisa ukusabalalisa okuhambelanayo kunye nokufana kobukhulu obungcolileyo.To

ukufikelela ngokungaguquguqukiyoukusebenza, kufuneka uqinisekise ukuba icebo lokucoca ulwelo loxinzelelo luzinzile.Ukuba iqondo lobushushu

utshintsho lwe-fluid, luyachaphazelai-viscosity yolwelo. Kule meko, uxinzelelo lwehla ngaphaya kwesihluzointo iya

ukwandisa kwaye ungaphumeleli umphumo wokucoca.

Ngoko ke, kufuneka ugcine ukushisa okusebenzayo kwesihluzi ngexesha lenkqubo yokucoca kunye

qinisekisa iubushushu bolwelo kunye noxinzelelo.Xa ucoca isihluzo, kufuneka ulandele i

inkqubo yokuhlamba umqolo echanekileyo.

Zisebenza Njani izihluzi zeSintered Metal?

Ungaqonda lula xa ujonga oku kulandelayoUmzobo womgaqo wokusebenza

Njengoko kulandelayo kungundoqo8-Iintloboyeumgaqo osebenzayo wokuhluza isinyithi, ndiyathemba ukuba kuya kuba luncedo kuwe

ukuqonda ngakumbiukuba njaniI-Sintered metal Filter inokuncedaulwelo lokuhluza, igesi kunye nelizwi.

1.) Ulwelo kunye neGesi yokuHlungwa/ukwahlula

Izihluzi ze-Sintered Metal zinokunciphisa okanye zisuse ngokupheleleyo i-particle ye-particulate kwi-gas okanye medium medium.

Umba othile unakozibandakanya kodwa zingaphelelanga kumasuntswana amisiweyo (intlenga, iitshiphu zetsimbi, ityuwa, njl.njl.),

i-algae, ibhaktheriya, i-fungi spores, kunye nokungafunwayoungcoliseko lwekhemikhali/lwebhayoloji. Ubungakanani bepore yesihluzo sesinyithi

inokwenza ukuba ibe luluhlu ukusuka ku-0.2 µm – 250 µm.

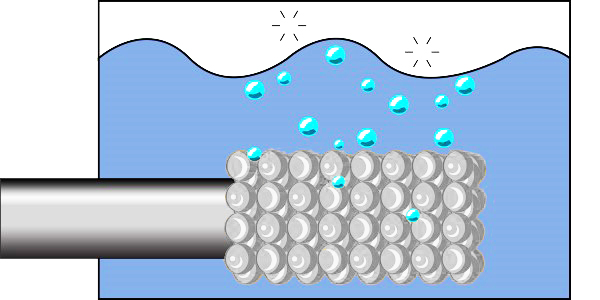

2.)Sparger

Ezinye zezicelo zokuLawula:

Soda Carbonization

IBeer Carbonization

IoksijiniUkuhluthwa kweOyile ezityiwayo

I-Sparging kukuqaliswa kwegesi kulwelo. Isetyenziselwa ukususa irhasi engafunekiyo enyityilisiweyo

(ukukhupha ioksijini) okanyeulwelo olunyibilikisiweyo oluguquguqukayo. Ingasebenzisa kwakhona ukwazisa igesi ibe lulwelo (carbonization).

Ukuhluma ngokwemveli kwadala amaqamzaububanzi be-6 mm. I-PM filtering sparging ivumela nokuba kuncinci

iqamza ububanzi, ngaloo ndlela ukwandisa indawo yomphezulu weamaqamza adala ukuchaphaza okusebenzayo ngakumbi

isicelo ngokunciphisa ixesha lenkqubo.

3.) IiVenti zokuphefumla

Izihluzi zetsimbi zetsimbi nazo zisetyenziswa njengeiindawo zokuphefumlakwiisilinda, iibhokisi zegiya, ii-manifolds, iinkqubo zehydraulic,

amadama, kunye nezinye iinkqubo. Imimoya yokuphefumula ivumela ukulinganisa koxinzelelo kunye nomoya / igesi ngaphakathi nangaphandle kwenkqubo

ngelixa uvala into ethile ekungeneni kwinkqubo. Iidiski zokucoca ubhedu zeSintered zisebenza ngokukodwa

kwiinjini zombane, ukuthintela ukungena kothuli, ukufuma, kunye nezinye izinto ezingcolisa ngelixa zivumela umoya.

ukutshintshiselana, okubalulekileyo ekugcineni indawo yangaphakathi yemoto kunye nokuqinisekisa ukuba kufanelekile

ukusebenza kunye nokuphila ixesha elide. Izihluzi zesinyithi zinokuphinda zihlanjwe ukuze zisuse i-particle nto, zinike ixesha elide

ubude bobomi njengento yokuphefumla kunezinye imidiya yokucoca.

4.) Ukukhuselwa koMva

Izihluzi zeMetal eziSintered zinokukhusela izixhobo ze-elektroniki njengesigqubuthelo, njengethemometha,

ezahlukeneyo izinzwa,isitshixoamacandelo eenkqubo zonyango, kunye nezinye iimveliso ezibuthathaka emanzini,

ulwelo, intlenga, uthuli, kunyeukuguquguquka koxinzelelo.

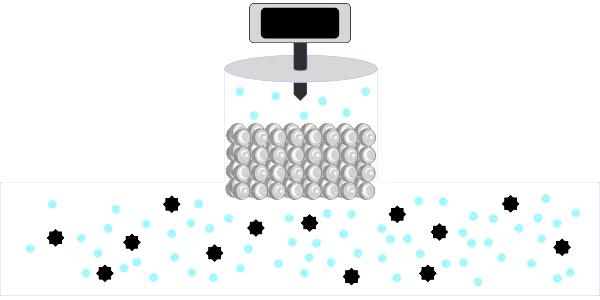

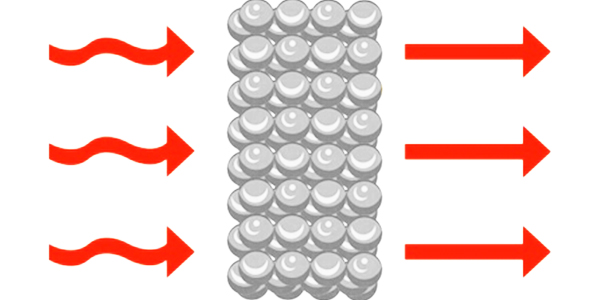

5.) Ulawulo lokuqukuqela (Ukubhuqa / ukudambisa)

Ikhethekileyoisihluzo sinteredinokulawula ukuhamba ngaphakathi komoya, igesi, ivacuum, kunye nenkqubo yokuhamba kwamanzi. I

iyunifomu yesihluzipore ubukhuluvumela ukulawulwa kokuhamba okungaguquguqukiyo kunye nokukhusela iivalvu, izinzwa,

kunye nantoni na enye esezantsikwinkqubo ukusukaungcoliseko. Ulawulo lokuhamba lusetyenziswa kwinto enjalo

izicelo njengezibali zepneumatic, ulawulo lokubonelela ngegesiizinto, kunye nokulibaziseka kwexeshaizinto kwi

izicelo zeemoto.

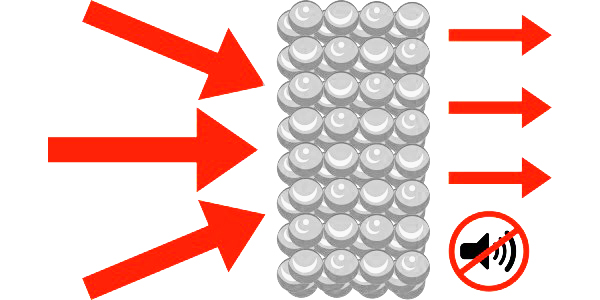

6.) IiSilencers zokukhupha umoya

Izihluzi ze-Sintered zinokudityaniswa okanye zibotshelelwe kwi-sinter-bonding kuyo nayiphi na into efunekayo, ezivumela ukuba zisebenze njengendawo.

exhaust silencer.Isihluzi asikwazi kuphela ukukhusela i-solenoids kunye nee-manifolds kwizinto ezingcolisayo ngaphakathi

inkqubo kodwa ikwanciphisa ingxoloinqanaba lokuphuma kwinkqubo. Iisithulisi sokukhupha umoyaizihluzi

kananjaloyehlisa umoya ovuthuzayo ngaphandle kwenkqubo, leyokunciphisa ungcoliseko wafting, Ukukhusela

indlela eyiyo.

7.) Ukuhamba / ukuLingana koxinzelelo

Izihluzi ze-Sintered zinokulingana kwaye zilawule izinga lokuhamba kwenkqubo kunye noxinzelelo. Ukulingana kuyakhusela

iinkqubo ngokuchasene nokunyukayolwelo kwaye idala ukuhamba ngendlela efanayo njengoko irhasi okanye ulwelo luhamba lunqumla

iipores ezifanayo.

Zisetyenziselwa ntoni izihluzi zeSintered?

Kulo mbuzo, Ngokwenyani abantu abaninzi baya kubuza Yintoni usetyenziso lwezihluzo zetsimbi ezisinkiweyo?

Emva kwenkqubo enzima ngolo hlobo, iphi i-sinterediikhatriji zokucoca isinyithizisetyenziswe?

Inyaniso kukuba ungazifumana ezi zihluzo kumashishini ahlukeneyo.

Izicelo eziqhelekileyo ziquka oku kulandelayo.

1) Ukulungiswa kweekhemikhali

Unokufumana izihluzi zetsimbi ezifakwe kwi-solvent yekhemikhali kunye ne-gas processing industry, kubandakanywa

ishishini lenyukliya.Umhlwa, ubushushu obuphezulu, kunye nokungaphenduli kwiikhemikhali zenza intsimbi ene-sintered

ihluza inzuzo eyahlukileyo kuyo

ishishini lokulungisa imichiza.

2) Ukucoca i-petroleum

Ukucoca i-petroleum, ukucoca ngokufanelekileyo izibaso ezahlukeneyo

Kufuneka sisebenzise izihluzi zetsimbi ezahlukeneyo ngokwenqanaba ledigri ukugqiba ukuhluzwa kwe

amafutha athile ukusukaisitokhwe sesondlo.Ewe, izihluzi zetsimbi ezine-sintered zinokukunceda ukufezekisa le njongo.

Ngenxa yokuba izihluzi zetsimbi aziphenduli ngamachiza ngamafutha.

Ngoko ke, i-fuel ethile iya kukhululeka kuyo nayiphi na into engcolileyo emva kokucoca.

Ukongeza, ungayisebenzisa kwiqondo lokushisa ukuya kwi-700 °, eqhelekileyo ekucoceni i-petroleum.

3.) Ukuveliswa kwamandla

Uveliso lombane owenziwe ngamanzi lufuna ukusebenza ngokuqhubekayo kweinjini yomoya. Sekunjalo, i

okusingqongileyo kwileyo turbineisebenza rhoqo ifuna ukuhluzwa ukufumana amanzi amaninzi kuwo

apho iturbine ingenabo nabuphi na ukungcola.

Ukuba i-injini yomoya igcwele kakhulu ubumdaka, iya kuphephuka kwaye ithintele i-injini yomoya ekujikelezeni,

kwaye ke i-injini yomoya iya kwenzaukuvelisa umbane. Ungasebenzisa izihluzi zetsimbi ezisinkiweyo ukuze uqinisekise

ukuveliswa kwamandla ngokufanelekileyo nangokufanelekileyo.

Ezi zihluzo zisetyenziselwa ukuvelisa umbane ngokuhluza amanzi asuka kwi-injini yomoya.

Ngenxa yokuba azikhukuliswanga ngamanzi, i-injini yomoya iya kusebenza ixesha elide.

4.) Ukuveliswa kwegesi yendalo

Enye indawo ebalulekileyo yokusetyenziswa kwezihluzo zetsimbi zetsimbi kukuveliswa kwegesi.

Izihluzi zetsimbi zetsimbi ziluncedo kakhulu kwimveliso yerhasi kuba azisebenzi ngerhasi,

kwaye unokuzisebenzisakwiindawo ezahlukeneyo.

5.) Ukutya kunye nesiselo

Izihluzi zesinyithi zikhupha izondlo eziyimfuneko kunye nejusi kwishishini lokulungisa ukutya kunye nesiselo.

Izihluzi zesinyithi zihluza ngokufanelekileyo kwaye zithintele ezi zondlo ukuba zingakhukuliseka ngexesha lokulungiswa.

Inzuzo yezihlungi zetsimbi ezifanayo kukuba aziphenduli ngokutya okanye iziphuzo ezithile.

Xa usebenzisa ezi zihluzi iqinisekisa umgangatho wenkqubo yakho yokuvelisa.

9. Loluphi uhloboIzihluzi zeSintered MetalHENGKO Ungabonelela ?

I-HENGKO inikezela nge-316L, i-316 kunye neefayili zetsimbi ze-bronze. imilo engundoqo njengoluhlu olulandelayo:

1.Isihluzo seNsimbi eNgatyiwayoIcwecwe,

2.IngenabalaIsihluzo sentsimbiUmbhobho,

3.Ingenabala Isihluzo sentsimbiIpleyiti,

4.Isihluzo seNsimbi eNgatyiwayoIindebe,

njl., nayiphi na imilo efunwa yiprojekthi yakho.

Ngokuqinisekileyo, siyabonelelaInkonzo ye-OEM

1.OEMUbume:IcwecweIndebe,Umbhobho, Icwecwe ect

2.LungiselelaUbungakanani, Ubude, Banzi, OD, ID

3.Ubungakanani bePore obulungiselelweyo /Imingxumaukusuka 0.1μm - 120μm

4.Lungiselela ukutyeba okwahlukileyo

5. I-Mono-layer, i-Multi-layer, i-Mixed Materials

6.Uyilo oludityanisiweyo kunye nezindlu ezingama-304 zensimbi engenasici

Ngeenkcukacha zakho ezingakumbi ze-OEM, nceda uqhagamshelane noHENGKO Namhlanje!

Usenayo nayiphi na imibuzo efana nokwazi iinkcukacha ezongezelelekileyo zeSensor yokuJonga ukufuma,

Nceda uzive ukhululekile ukuQhagamshelana nathi ngoku.

Kwakhona UnakoSithumele i-imeyileNgqo Ngokulandelayo:ka@hengko.com

Siza kuthumela umva ngeeyure ezingama-24, enkosi ngesigulana sakho!

Thumela umyalezo wakho kuthi:

Ixesha lokuposa: Aug-20-2022