-

25 Micron Stainless Steel 316L Porous Metal Sintered Filter Cartridge for Ulwelo lwerhasi Ke...

Imveliso Chaza i-HENGKO iityhubhu zokucoca insimbi engenasici zenziwe nge-sintering 316L yemathiriyeli yomgubo okanye i-multilayer ye-wire mesh yensimbi engenasici kumaqondo obushushu aphezulu....

Jonga iinkcukacha -

Unyango olulungiselelweyo 304 316 316L iikhatriji zentsimbi yesihluzo esingenasici esivela kwi-HENGKO

Yenziwe nge-multi-layer sintered 316 okanye 304 isihluzi sentsimbi estainless, ineempawu zokumelana nobushushu, ukumelana noxinzelelo, kunye nokumelana nomhlwa.T...

Jonga iinkcukacha -

Uxinzelelo oluphezulu oluxhathisayo 316l sintered steel stainless steel mesh filter cartridge

Izihluzi ze-Sinter wire mesh zihlala zisetyenziselwa ukucocwa kunye nokuhluzwa kolwelo kunye negesi, ukwahlula kunye nokubuyiselwa kwamasuntswana aqinileyo, ukupholisa umoya...

Jonga iinkcukacha -

I-Micro powder sintered 304 316L yentsimbi engenasici kwimizi-mveliso yokuqokelela ioyile yokucoca imoto...

Izihluzi zekhandlela kunye neetyhubhu ezinama-porous zide, izihluzi ze-cylindrical ezineendonga ezincinci, oko kukuthi, zinomlinganiselo ophezulu wobude ukuya ku-diameter. Iisilinda zinokuba ziholoholo okanye...

Jonga iinkcukacha -

Sintered steel stainless steel mesh air filter cartridge yokususwa kothuli okanye amanzi acocekileyo

Izihluzi ze-Sinter wire mesh zihlala zisetyenziselwa ukucocwa kunye nokuhluzwa kolwelo kunye negesi, ukwahlukana kunye nokubuyiselwa kwamasuntswana aqinileyo, i-coolin yokuphefumula...

Jonga iinkcukacha -

ukuchaneka sintered micron metal porous ubhedu SS 316 steel stainless isihluzo ikhandlela powd...

Imveliso Chaza i-HENGKO intsimbi yesihluzo sentsimbi ecocekileyo yenziwe nge-sintering 316L yemathiriyeli yomgubo okanye i-multilayer yensimbi engenasici yocingo olunemesh kubushushu obuphezulu...

Jonga iinkcukacha -

micron sintered 316L steel stainless cartridge filter yokunyanga amanzi oyile

Izihluzi ze-Sintered wire mesh zihlala zisetyenziselwa ukucocwa kunye nokuhluzwa kolwelo kunye negesi, ukwahlula kunye nokubuyiselwa kwamasuntswana aqinileyo, ukuphefumla kupholile...

Jonga iinkcukacha -

Ukusebenziseka kwakhona ukumelana nobushushu obuphezulu beMicrons Mesh Sintering Metal Filter Cartridge

Izihluzi ze-Sinter wire mesh zihlala zisetyenziselwa ukucocwa kunye nokuhluzwa kolwelo kunye negesi, ukwahlukana kunye nokubuyiselwa kwamasuntswana aqinileyo, i-coolin yokuphefumula...

Jonga iinkcukacha -

Uhlobo lwekhandlela i-Sintered 316L yentsimbi engenastainless mesh filter reusable cartridge

I-HENGKO ibonelela ngengqokelela ebanzi yeekhatriji zokucoca intsimbi estainless eyenzelwe ukusetyenziswa kuluhlu olubanzi lwamashishini, kubandakanya nepetrochemicals...

Jonga iinkcukacha -

5 40 micron sintered steel stainless steel porous amafutha amafutha / umoya / uthuli isihluzo ucingo umnatha ca...

Izihluzi ze-Sinter wire mesh zihlala zisetyenziselwa ukucocwa kunye nokuhluzwa kolwelo kunye negesi, ukwahlukana kunye nokubuyiselwa kwamasuntswana aqinileyo, i-coolin yokuphefumula...

Jonga iinkcukacha -

Ikhatriji yokucoca umoya wentsimbi ecinezelweyo yocingo olunameshi yokucoca umoya kunye neg...

I-Sintering yinkqubo ebandakanya ukusetyenziswa kobushushu kunye noxinzelelo lokubopha iindawo zoqhagamshelwano zazo zonke iingcingo kunye ukwenza umnatha wocingo odityanisiweyo ngokukhuselekileyo ...

Jonga iinkcukacha -

1.0-100um sintered metal porous steel stainless cartridge filter mesh yenza kulwelo...

Izihluzi ze-Sinter wire mesh zihlala zisetyenziselwa ukucocwa kunye nokuhluzwa kolwelo kunye negesi, ukwahlukana kunye nokubuyiselwa kwamasuntswana aqinileyo, i-coolin yokuphefumula...

Jonga iinkcukacha -

I-Anti-Corrosion Microns Powder Porous Sintered Metal Filter Cartridge For Filtration System

I-HENGKO yenza iityhubhu zokucoca ezinabileyo ezibonelela ngeendlela ezahlukeneyo kuyilo njengoko zinokuba mngxuma okanye zingaboni kunye nobukhulu bodonga obuyi-1mm. Ezi mveliso c...

Jonga iinkcukacha -

Isihluzi sekhatriji yentsimbi engenaziphene yoxinzelelo oluphezulu lokucoca umoya oluqinileyo ...

I-HENGKO yenza izixhobo zayo zetsimbi ezirhabaxa ngobushushu bokuphatha i-316L yemathiriyeli yomgubo okanye i-multilayer yentsimbi engenasici yocingo olunamaqondo obushushu aphakamileyo. Babo...

Jonga iinkcukacha -

Uxinzelelo oluphezulu lokumelana nobushushu obunokuphinda busebenziseke iimicrons ezineporous metal bronze isihluzo sobhedu ...

Iityhubhu zeHENGKO ezinabileyo zokucoca zinokuba nomngxuma okanye zingaboni kwaye zibenodonga olungqingqwa oluyi-1 mm. Zenziwe nge-isostatic compaction yomgubo kwi-mo eguquguqukayo ...

Jonga iinkcukacha -

IiCartridges zeSintered Filtered for Medical Filtration Applications -HENGKO

I-HENGKO iphuhlise i-membrane yebakala yonke yesinyithi yokucoca usetyenziso lwezonyango. Esi sixhobo sifanelekile kwizicelo zonyango ...

Jonga iinkcukacha

Zisetyenziselwa ntoni izihluzi zeNsimbi ezineNgxaki eziSintered?

Izihluzi zesinyithi ezinamarhashalala ziguquguquka kakhulu kwaye zifumana usetyenziso kuluhlu lwamashishini

ngenxa yokuqina kwazo, ukumelana nobushushu obuphezulu kunye noxinzelelo, kunye nokukwazi ukumelana

iindawo ezonakalisayo. Nalu usetyenziso oluqhelekileyo kwezi zihluzo:

1. Uhluzo lwezicelo:

* Ukuhluzwa kwegesi:

2. UkuBuyiselwa kweCatalyst:

Kwii-reactors zekhemikhali, izihluzo zetsimbi ezisiyiweyo zisetyenziselwa ukubuyisela izinto ezibiza imali eninzi ezisetyenziswa kwinkqubo yokusabela

3. I-Sparing kunye ne-Gas Diffusion:

Ezi zihluzo zisetyenziswa kwii-bioreactors kunye neenkqubo zokuvundiswa ukwazisa igesi kulwelo ngendlela elawulwayo,

4. Izicelo zokukhupha umoya:

Kwimizi-mveliso yeemoto kunye ne-aerospace, iminyango yentsimbi ene-sintered ikhusela izixhobo ezinovakalelo ngokulinganisa uxinzelelo

5. I-Fluidization:

Isetyenziswa kumashishini okuphatha umgubo ukwenza umgubo omninzi, uqinisekisa ukuhamba kakuhle kunye nokuthintela ukuvaleka.

6. ISampuli yeAerosol:

Izihluzi zetsimbi zetsimbi zisetyenziswa kwizixhobo zokubeka iliso kwendalo ukuqokelela iisampulu zeaerosol ukuze zihlalutywe.

7. Ukutshintshana kobushushu:

Ngenxa ye-thermal conductivity ephezulu kunye nokumelana nokutshintsha kobushushu, ezi zihluzo zikwasetyenziswa

Iimpawu eziphambili zePorous Metal Filter Cartridges :

1. Ukubunjwa kwezinto

Izihluzi zesinyithi ezinamazinyo ziqhele ukwenziwa kwiintsimbi ezixutyiweyo njengentsimbi engatyiwa (304, 316L),

i-titanium, kunye nezinye i-alloys ezifana ne-Hastelloy kunye ne-Inconel. Olu qulunqo lubonelela ngokugqwesileyo

amandla omatshini kunye nokuchasana nokugqwala kunye nokutshatyalaliswa kwe-thermal.

2. I-Porosity elawulwayo

Inkqubo yokuvelisa ivumela ulawulo oluchanekileyo malunga nobukhulu be-pore, ukusuka kwi-0.5 ukuya kwi-200 microns.

Olu lawulo luququzelela ukuhluzwa kweengqungquthela kumanqanaba ahlukeneyo, okwenza ukuba afanelekele i-microfiltration

yeegesi kunye nolwelo phantsi koxinzelelo oluphezulu kunye neemeko zobushushu.

3. Amandla aphezulu kunye nokuqina

Ezi zihluzo zinokumelana noxinzelelo oluphezulu oluphezulu (ukuya kuthi ga kwi-3000 psi) kunye neemeko zokusebenza ezinzima,

ukuqinisekisa ubomi benkonzo ende kunye nokuthembeka kwizicelo ezifunwayo.

4. Ukucoceka kunye nokusebenziseka kwakhona

Iikhatriji zokucoca isinyithi zentsimbi ziyilelwe ukuba zicocwe kwaye ziphinde zisetyenziswe, ngokufuthi ngeendlela ezinje

i-backflushing okanye ukucocwa kwe-ultrasonic. Olu phawu alunciphisi iindleko zokusebenza kuphela kodwa kwakhona

kwandisa ubomi babo.

5. I-Thermal kunye ne-Chemical Resistance

Ezi zihluzo zigcina ukusebenza kumaqondo okushisa aphezulu (ukuya kwi-930 ° C) kwaye zichasene noluhlu olubanzi

yeekhemikhali, ezenza zibe zilungele izicelo kwi-chemical processing, amayeza, kunye nokutya kunye

amashishini eziselo.

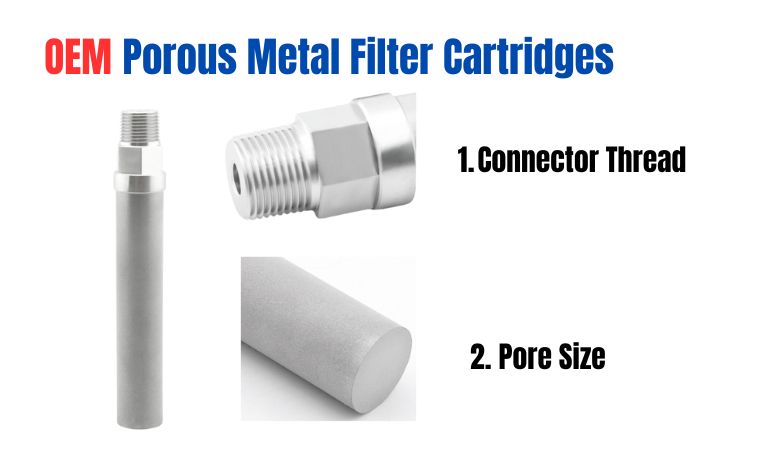

6. Iinketho zokwenza ngokwezifiso

Abavelisi banikezela ngokwenziwa ngokwezifiso ngokwemathiriyeli, ubungakanani bepore, kunye nemilinganiselo yokuhlangabezana nokuthe ngqo

iimfuno zesicelo.

Oku bhetyebhetye kuvumela ukusebenza ngokugqibeleleyo okulungiselelwe iimfuno zamashishini ahlukeneyo.

7. Uxinzelelo oluphantsi lwehla

Uyilo lwezihluzi zetsimbi ezinabileyo ziqinisekisa ukuhla koxinzelelo oluphantsi ngaphaya kwendawo yokucoca, eyongeza

amazinga okuhamba kunye nokusebenza kakuhle kwenkqubo ngelixa kuncitshiswa ukusetyenziswa kwamandla.

8. Izicelo eziNyenziwe ngeendlela ezahlukeneyo

Ezi zihluzo zisetyenziswa kumacandelo ahlukeneyo, kubandakanya i-aerospace, izithuthi, i-oyile kunye negesi, kunye namandla.

ukuvelisa, ukwenzela izicelo ezifana nokuhluzwa, ulawulo lokuqukuqela, kunye nokunciphisa ingxolo.

Isishwankathelo, iikhatriji zokucoca isinyithi zenzelwe ukusebenza okuphezulu kunye nokuguquguquka, ukwenza

ziyinxalenye ebalulekileyo kwiinkqubo ezininzi zokuhluza kwimizi-mveliso.

Ulwakhiwo lwabo olomeleleyo kunye nokukwazi ukulungelelaniswa kwizicelo ezithile kuqinisekisa ukuba bayahlangabezana

Iimfuno ezingqongqo zeenkqubo zale mihla zokwenziwa kwemveliso.

Iindidi zeekhatriji zeSihluzo zeMetal ezineNgxaki

Iikhatriji zokucoca intsimbi zisetyenziswa kakhulu kumashishini ahlukeneyo ngenxa yeempawu zazo zokucoca.

ukuqina, kunye nokumelana nemichiza. Ngokuqhelekileyo zakhiwe ukusuka kumgubo wesinyithi owenziwe nge-sintered, njenge

intsimbi, ubhedu, okanye nickel.

Nazi ezinye iintlobo eziqhelekileyo zeekhatriji zokucoca isinyithi:

1.Ngokusekwe kubungakanani bePore:

*Kunzima:Iisayizi ezinkulu zepore, zilungele ukususa amasuntswana amakhulu afana nobumdaka, isanti, kunye nobutyobo.

*Kulungile:Ubukhulu obuncinci bepore, bulungele ukususa amasuntswana acolekileyo njengebhaktiriya, iintsholongwane, kunye ne-colloids.

*I-Ultrafine:Ubungakanani bepore encinci kakhulu, esetyenziselwa ukucoca okuphezulu kakhulu, njengokususa izinto eziqinileyo kunye nokungcola.

2. Ngokusekwe kubume:

*Isilinda:Eyona milo ixhaphakileyo, inika indawo enkulu yendawo yokuhluza.

*Icetyisiwe:Uyilo olusongelweyo okanye olucekethekileyo, ukwandisa indawo yokucoca kunye nokuphucula ukusebenza kakuhle.

*Idiskhi:I-flat, ii-cartridges ezine-disc, ezifanelekileyo kwizicelo ezithile okanye izixhobo.

3. Ngokusekwe kuMathiriyeli:

*Yenziwe ngentsimbi eshayinayo:Eyona nto ixhaphakileyo ngenxa yokumelana nokugqwesa kwayo okugqwesileyo, amandla, kunye nokunyamezela ubushushu obuphezulu.

*Ubhedu:Inika ukuxhathisa okulungileyo kokutya kunye ne-thermal conductivity, ehlala isetyenziswa kwizicelo zokutshintsha ubushushu.

*Nickel:Ibonelela ngokumelana neekhemikhali ezigqwesileyo kunye nokusebenza okuphezulu kweqondo lobushushu, ilungele iindawo ezinzima.

*Ezinye iintsimbi:Ngokuxhomekeke kwiimfuno ezithile, ezinye iintsimbi ezifana ne-titanium, i-aluminiyam, okanye i-tungsten zingasetyenziswa.

4. Ngokusekwe kuShicilelo lweMechanism:

*Uhluzo olunzulu:Amalungu avaleleke ngaphakathi kwesakhiwo se-porous sesihluzo.

*UHluzo lomphezulu:Amalungu abanjwa kumphezulu wesihluzo.

*Uhluzo lweSieve:Amalungu avaliwe ngokwasemzimbeni bubungakanani bepore.

Imiba ephambili omawuyithathele ingqalelo xa ukhetha iKhatriji yesihluzi seMetal enePorous:

*Ubungakanani beNcam:Ubungakanani bamaqhekeza kufuneka asuswe.

*Umgangatho wohambo:Umyinge wokuqukuqela ofunekayo ngesihluzo.

*Ukuhla koxinzelelo:Uxinzelelo oluvumelekileyo lwehla ngapha kwesihluzo.

*Ukuhambelana kweMichiza:Ukuhambelana kwezinto zokucoca kunye nolwelo oluhluzwayo.

*Ubushushu:Ubushushu bokusebenza kwesihluzi.

* Ukucoca kunye nokuhlaziywa kwakhona:Indlela yokucoca okanye ukuhlaziya kwakhona isihluzi.

Ngokuqonda ezi ntlobo zahlukeneyo kunye nemiba, ungakhetha eyona cartridge yentsimbi efanelekileyo yokucoca isinyithi kwiimfuno zakho zokucoca.

Uzikhetha njani iikhatriji zesihluzi sesinyithi esineNgxaki eziLungileyo?

Kukho izinto ezininzi omele uziqwalasele xa ukhetha iikhatriji zentsimbi zokucoca isinyithi

yakhoizixhobo zokucoca okanye iprojekthi. Apha sidwelisa iingongoma eziziintloko ezisi-8 omele uzijonge.

1. Ubungakanani beNcam:

*Qinisekisa ubungakanani bamasuntswana ekufuneka uwasuse.

*Khetha ikhatriji enobungakanani bepore encinci kunamasuntswana aza kuhluzwa.

2. Inqanaba lokuHamba:

*Qwalasela umlinganiselo wokuqukuqela ofunekayo ngesihluzo.

*Khetha ikhatriji enendawo engaphezulu kunye nobukhulu bepore enokumelana nesantya sokuqukuqela esifunekayo

ngaphandle kokuhla koxinzelelo olugqithisileyo.

3. Ukwehla koxinzelelo:

*Vavanya ukuhla koxinzelelo oluvumelekileyo kwisihluzi.

*Khetha ikhatriji enoxinzelelo oluphantsi ukunciphisa ukusetyenziswa kwamandla kunye nokuqinisekisa ukusebenza kakuhle.

4. Ukuhambelana kweMichiza:

*Vavanya ukuhambelana kwemichiza yemathiriyeli yokucoca kunye nolwelo oluhluzwayo.

*Khetha ikhatriji eyenziwe ngezinto ezikwaziyo ukumelana nomhlwa kunye nohlaselo lwekhemikhali lulwelo.

5. Ubushushu:

*Misela ubushushu bokusebenza kwesihluzi.

*Khetha ikhatriji enokumelana neqondo lobushushu elilindelekileyo ngaphandle kokubeka esichengeni ukusebenza kwayo okanye imfezeko.

6. Ukucoca kunye noHlaziyo:

*Qwalasela indlela kunye namaxesha okucoca okanye ukuhlaziya kwakhona isihluzi.

*Khetha ikhatriji ekulula ukuyicoca okanye ukuyihlaziya, kuxhomekeke kwisicelo esikhethekileyo kunye neemfuno zokucoca.

7. Imidiya yesihluzi:

*Vavanya uhlobo lwemidiya yokucoca esetyenziswa kwikhatriji.

*Qwalasela iinketho ezinje ngomgubo wentsimbi osiniweyo, umnatha wocingo olukiweyo, okanye ezinye izinto ezirhabaxa, ngokusekwe kwiimfuno zakho ezithile.

8. Uyilo lweCartridge:

*Vavanya uyilo lwekhatriji, enje ngecylindrical, pleated, okanye idisc-shaped.

*Khetha uyilo oluhambelana nesixhobo sakho kwaye lubonelela ngokusebenza okufunekayo kokucoca.

9. Umenzi kunye noMgangatho:

*Phanda abavelisi abathembekileyo beekhatriji zokucoca isinyithi.

*Khetha ikhatriji kumenzi onerekhodi eqinisekisiweyo yomgangatho nokuthembeka.

FAQ

1. Ziziphi iikhatriji ze-metal filter kwaye zisebenza njani?

Iikhatriji zesinyithi esinezingxobo zentsimbi zizixhobo zokuhluza ezenziwe ngeentsimbi ezisiniweyo ezinobume obuqinileyo, obunemingxuma.

Ezi khatriji ziqhele ukwakhiwa ngokudibanisa umgubo wentsimbi phantsi kobushushu obuphezulu kunye noxinzelelo ukwenza okuqinileyo,

kodwa i-porous, i-material. I-porosity inokulawulwa ngokuchanekileyo ukujolisa ubungakanani besuntswana elithile.

Njengoko ulwelo okanye iigesi zidlula kwisihluzi, amasuntswana amakhulu kunobungakanani bepore ayabanjwa, asuswe ngokufanelekileyo kumsinga.

Lo matshini ubalulekile kwizicelo ezifuna ukucoceka okuphezulu kunye nokusebenza kakuhle, njengokwenza amayeza,

ukusetyenzwa kweekhemikhali, kunye neenkqubo ezibalulekileyo zokulawula ulwelo.

2. Zeziphi izinto ezisetyenziswa ngokuqhelekileyo xa kusenziwa iikhatriji zokucoca isinyithi?

Ezona mathiriyeli ziqhele ukusetyenziswa ukwenza iikhatriji zentsimbi yokucoca intsimbi zibandakanya intsimbi engatyiwa, i-titanium, kunye ne-nickel alloys.

Ezi zixhobo zikhethwa ngenxa yeempawu zazo eziqinileyo zoomatshini, ukuchasana nokugqwesa okugqwesileyo, kunye nokukwazi ukumelana nokugqithisa

amaqondo obushushu kunye noxinzelelo. Insimbi engenasici ithandwa ngokubanzi kwizicelo ngokubanzi ngenxa yokuqina kwayo kunye nokusebenza kakuhle kweendleko,

ngelixa i-titanium kunye ne-nickel alloys zikhethwa kwindawo ezonakalisa kakhulu okanye zifuna umlinganiselo omkhulu wobunzima bobunzima.

3. Zeziphi iingenelo eziphambili zokusebenzisa iikhatriji zesinyithi esinezingxobo ngaphezu kwezinye iintlobo zokucoca?

Iikhatriji zokucoca isinyithi zibonelela ngeenzuzo ezininzi ezahlukeneyo:

*Ukumelana nobushushu obuphezulu: Banokusebenza ngokufanelekileyo phantsi kweemeko eziphezulu zokushisa, okuyimfuneko kwiinkqubo ezifana nokucoca igesi eshushu kunye ne-catalysis.

*Ukunyangwa kweMichiza: Izihluzi zetsimbi zingena kwimichiza emininzi, zizenza zifaneleke kwiindawo ezinobume bekhemikhali apho izihluzi ze-polymer ziya kuthotywa.

*Ukomelela kunye noKuhlala ixesha elide: Izihluzi zetsimbi ziyakwazi ukumelana noxinzelelo oluphezulu kunye noxinzelelo olunzima lomatshini ngaphandle kokukhubazeka okanye ukuphuka.

*Inokuvuselelwa kwaye isebenziseka kwakhona: Ziyakwazi ukucocwa kwaye ziphinde zisetyenziswe ngamaxesha amaninzi, zinika ubomi obude benkonzo kunye nokunciphisa iindleko zokutshintshwa kunye nenkunkuma.

*Inokwenzeka: I-porosity kunye noyilo lwejometri lunokwenziwa ngokwezifiso ukuhlangabezana neemfuno ezithile zokucoca, ukubonelela ukuguquguquka kwizicelo ezahlukeneyo.

4. Kweziphi izicelo ezisetyenziswa kakhulu iikhatriji zokucoca isinyithi?

Iikhatriji zokucoca isinyithi zisetyenziswa kakhulu kwizicelo ezininzi ezibalulekileyo, kubandakanya:

*Ishishini leMichiza: Ukucoca iikhemikhali ezicocekileyo kunye nokukhuselwa kweebhedi ze-catalyst ekungcoleni.

*Amayeza: Kwimveliso yee-APIs (Ii-Active Pharmaceutical Ingredients) apho ulawulo longcoliseko lubalulekile.

*Ukutya kunye nesiselo: Kwiinkqubo zokucoca iintsholongwane ukuqinisekisa ukhuseleko lwemveliso kunye nomgangatho.

*Ioyile neGesi: Ekuqhubekeni komsinga kunye nokwehla komlambo ukususa amasuntswana kumafutha kunye nokukhusela izixhobo ezibuthathaka.

*Isiphekepheke kunye neZithuthi: Ukucoca ulwelo lwe-hydraulic kunye namafutha aphantsi kweemeko zokusebenza ezigqithisileyo.

5. Iikhatriji zokucoca isinyithi zigcinwa kwaye zicocwe njani?

Ukugcinwa kunye nokucocwa kweekhatriji ze-metal filter ye-porous kuxhomekeke kakhulu kuhlobo longcoliseko kunye nomzimba

iimpawu zemathiriyeli yokucoca. Iindlela zokucoca eziqhelekileyo ziquka:

*Ukubuyisela umva: Ukubuyisela umva isalathiso sokuhamba ukugxotha amasuntswana.

*Ukucoca ngeUltrasonic: Ukusebenzisa amaza esandi esinezandi eziphezulu ukususa amasuntswana amahle.

*UkuCocwa kweMichiza: Ukusebenzisa izinyibilikisi okanye iiasidi ukunyibilikisa ungcoliseko.

*Ubushushu obuphezulu bokuBuyela: Ukusebenzisa ubushushu ukwenza i-oxidize imathiriyeli ephilayo.

Ukugcinwa rhoqo kunye nokucoca ngokufanelekileyo kunokwandisa kakhulu ubomi beekhatriji zokucoca, okwenza kube yisisombululo esineendleko kwizicelo ezininzi zoshishino.