-

OEM sintered metal porous isihluzi sobhedu media inwebu izihluzi

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zicaciswe ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

3-90 micron ubhedu sintered kabini-evulekileyo iziphelo isihluzo ityhubhu yokucokisa kunye s...

Iityhubhu zeHENGKO ezinabileyo zokucoca zinokuba nomngxuma okanye zingaboni kwaye zibenodonga olungqingqwa oluyi-1 mm. Zenziwe nge-isostatic compaction yomgubo kwi-mo eguquguqukayo ...

Jonga iinkcukacha -

Iimicrons ezi-3 ukuya kwezi-90 zesinyithi esinezibilini zokucoca umbhobho wokucoca ubhedu olungele isihluzo se-oyile...

Iityhubhu zeHENGKO ezinabileyo zokucoca zinokuba nomngxuma okanye zingaboni kwaye zibenodonga olungqingqwa oluyi-1 mm. Zenziwe nge-isostatic compaction yomgubo kwi-mo eguquguqukayo ...

Jonga iinkcukacha -

Custom 35 50 microns fuel filter sintered bronze filter disc disk umsebenzi onzima kunye...

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zicaciswe ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

Uxinzelelo oluphezulu lokumelana nobushushu obunokuphinda busebenziseke iimicrons ezineporous metal bronze isihluzo sobhedu ...

Iityhubhu zeHENGKO ezinabileyo zokucoca zinokuba nomngxuma okanye zingaboni kwaye zibenodonga olungqingqwa oluyi-1 mm. Zenziwe nge-isostatic compaction yomgubo kwi-mo eguquguqukayo ...

Jonga iinkcukacha -

Metal powder sintered porous porosity bronze 316 steel stainless izihluzi micro discs

Isihluzi se-bronze esine-porous sintered senziwe ngomgubo we-alloy we-copper sintered kubushushu obuphezulu. Inokuchaneka okuphezulu kokucoca, umoya olungileyo we-permeabili...

Jonga iinkcukacha -

Ukwenziwa ngokwezifiso zakho 15 45 90 micron powder sintered ubhedu ubhedu oluneporous metal oli fi...

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zicaciswe ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

Isihluzi sesinyithi se-porous diski yesikwere se-micron sintered ishidi lokucoca ubhedu

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zicaciswe ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

iityhubhu zokucoca zesinyithi esinezingxobo sobhedu isilinda esinamanzi sokucoca umoya we-ptocess kunye...

Iityhubhu zeHENGKO ezinabileyo zokucoca zinokuba nomngxuma okanye zingaboni kwaye zibenodonga olungqingqwa oluyi-1 mm. Zenziwe nge-isostatic compaction yomgubo kwi-mo eguquguqukayo ...

Jonga iinkcukacha -

sintered metal isihluzo idiskhi yokucoca amanzi amdaka, 5 20 micron 304 316L stainless ste...

Amaphepha okucoca ubunzulu asetyenziselwa ukususa amasuntswana kulwelo. Oku kuthetha ukuba ulwelo lunokucaca-, lucoleke- okanye luhluzwe iintsholongwane. Amaphepha okucoca alungele...

Jonga iinkcukacha -

ibronze filter cylinder microporous powder sintered bronze steel stainless steel 316L indebe yokucoca

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zicaciswe ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

hepa sintered ubhedu steel stainless steel icwecwe elinezingxobo zentsimbi yomatshini wokucoca umoya/oyile

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zicaciswe ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

I-porosity ephezulu ye-sintered metal micron replacement porous powder sintered bronze oil filte...

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zicaciswe ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

Isiko lomgubo wentsimbi yefilter sheet microns porosity bronze sheets filter for wat...

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zicaciswe ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

5 10 micron sintered porosity umgubo intsimbi stainless 316L ubhedu / ubhedu isilinda yesihluzi

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zicaciswe ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

iindawo zokucoca i-Sintered kunye ne-micron sintered metal porous filter bronze disc

Imveliso Chaza i-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zibe nokuchazwa ngokulula kunye nomlinganiswa...

Jonga iinkcukacha -

Isihluzi samalungu obhedu obhedu onesingxobo esinejiyometri...

I-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zicaciswe ngokulula ngeempawu kunye noqwalaselo...

Jonga iinkcukacha -

Micron metal porous sintered umgubo metal izihluzo ring yobhedu

Imveliso Chaza iityhubhu ze-HENGKO ezinabileyo zokucoca zinokuba zimngxuma okanye zingaboni kwaye zibe nodonga oluncinci lwe-1 mm. Zenziwe nge-isostatic compaction yomgubo ...

Jonga iinkcukacha -

I-3-90 ye-micron yesinyithi ye-bronze powder sintered filter cylinder tube ye-filtration system

Iityhubhu zeHENGKO ezinabileyo zokucoca zinokuba nomngxuma okanye zingaboni kwaye zibenodonga olungqingqwa oluyi-1 mm. Zenziwe nge-isostatic compaction yomgubo kwi-mo eguquguqukayo ...

Jonga iinkcukacha -

microns isiko sintered porous bronze monel inconel 316L steel stainless steel filter e...

Imveliso Chaza i-HENGKO yenza izinto zokucoca kuluhlu olubanzi lwemathiriyeli, ubungakanani, kunye nokufakwa ukuze zibe nokuchazwa ngokulula kunye nomlinganiswa...

Jonga iinkcukacha

Yintoni iSintered Powder Metal Filter kunye neempawu eziphambili

Izihluzo zesinyithi esinomgubo we-Sintered luhlobo lwesihluzo esenziwe ngokutshisa, okanye ukufudumeza, umxube womgubo wesinyithi

bade badibane benze isakhiwo esiqinileyo. Le nkqubo idala i-porous material enokuthi ibambe

ungcoliseko kunye nokunye ukungcola, kuyenza ibe sisihluzo esisebenzayo kwizicelo ezahlukeneyo.

1.High Porosity

Enye yeenzuzo eziphambili ze-sintered powder metal filters zaboi-porosity ephezulu. Imingxuma kwisihluzo

zincinci kakhulu, ngokwesiqhelo ziqala ngobukhulu ukusuka kwi-0.2 ukuya kwi-10 microns, ezivumela ukuba zisuse ngempumelelo

uluhlu olubanzi lwezinto ezingcolisayo ezivela kulwelo kunye neegesi. Ibenza balungele ukusetyenziswa kwiimoto,

i-aerospace, kunye nemizi-mveliso yezonyango, apho ucoceko nobunyulu buyimfuneko.

2.Ukuqina

Enye inzuzo yezihluzo zetsimbi ze-sintered zetsimbi yazoukuqina. Inkqubo sintering idala a

eyomeleleyo, isakhiwo esomeleleyo ukumelana ukunxitywa kunye nokukrazula, ukuvumela isihluzo ukumelana noxinzelelo oluphezulu kunye

amaqondo obushushu ngaphandle kokonakala okanye ukwaphuka. Ibenza balungele ukusetyenziswa kwiindawo ezibango,

njengeenjini okanye ezinye iimatshini ezisebenza kakhulu.

3. Ukucoca ngokulula

Omnye wemiceli mngeni wokusebenzisa izihluzi zetsimbi ezisinyibilikileyo kukuba zinokuba njalokunzima ukucoca kunye nokusebenzisa kwakhona.

Ngenxa yokuba iipores zincinci, ukususa ukungcola okubanjwe kwisihluzi kunokuba nzima, kuyenze

Kuyimfuneko ukubuyisela isihluzi endaweni yokuyicoca. Kungaba yindleko, ngakumbi kwizicelo apho i

isihluzo sisetyenziswa rhoqo. Ngokuqinisekileyo unayo indlela yokucoca.

Ngaphandle kolu thintelo, izihluzi zetsimbi ze-sintered zisetyenziswa ngokubanzi ngenxa yokusebenza kwazo kunye nokuqina.

Ziyinxalenye ebalulekileyo kwiinkqubo ezininzi zoshishino kunye nemveliso, ezinceda ekuqinisekiseni

ubunyulu kunye nomgangatho wolwelo kunye neegesi. Ngokukwazi kwabo ukubambisa uluhlu olubanzi lwezinto ezingcolileyo kunye nokumelana

iindawo ezifunayo, izihluzi zesinyithi ze-sintered zisisixhobo esibalulekileyo sokugcina ukusebenza

kunye nokuthembeka koomatshini kunye nezixhobo.

Kutheni i-HENGKO i-Sintered Powder Metal Filters

Nikela ngeZisombululo zoHluzo eziBalaseleyo

Iindidi zethu zezisombululo zesihluzo sesinyithi somgubo we-sintered zibalasele kwiintlobo ngeentlobo zezicelo ezifunwayo;

sinter enemingxumaiipropati ezizodwa metal kaThixo zisetyenziswa ezahlukeneyo high-uxinzelelo izixhobo sparging isohlwayo kunye

ukuhanjiswa okufanayo kweegesi zibe lulwelo.

Izihluzi zesinyithi ezinomgubo we-sintered, rhoqo kunye ne-flow-optimized area connectors, zisetyenziselwa ukwahlula

izinto eziqinileyo ezivela kwimisinga yerhasi ngaphakathiiinkqubo ezahlukeneyo. Iimpawu eziphambili zezi zilandelayo:

1. Ukumelana nobushushu obuphezulu, ukuzinza kweThermal ukuya kuthi ga kwi-950 ° C

2. Ifanelekile kuxinzelelo oluphezulu olwahlukileyo

3. Ukumelana ne-corrosion ephezulu

4. Isidibanisi esidityanisiweyo sinter eyodwa

5. Isakhiwo esizixhasayo esinamandla amakhulu omatshini

6. Ukusebenza kakuhle kwe-pulse back

7. Akukho welding of media porous

8. Uyilo oluguquguqukayo, iimilo ezahlukeneyo ezikhoyo, kunye nokulungelelanisa

9. Ngaphezulu kwe-10,000 eyahlukeneyo yomgangatho kunye nobukhulu besiko / iimilo ezikhoyo

10. Eyona nto ilungiselelwe igesi elinganayo/ulwelo

11. Yamkela ukutya-iklasi ye-316L kunye ne-304L yensimbi engenasici okanye ubhedu

12. I-Easy Cleanable and Reusable Materials

EZETHU zobuGcisa

Njengomvelisi okumgangatho ophezulu weemveliso zokucoca isinyithi, i-HENGKO ibonelela ngezisombululo zetekhnoloji zangoku.

kubushushu obuphezulu kunye neendawo ezinobungozi.

Ngokwesiqhelo izinto zokucoca umgubo wentsimbi zenziwe ngentsimbi engatyiwa, ubhedu, ialloyi esekwe nickel, kunye netitanium kwaye zinako.

udityaniswe ngaphandle komthungo kunye nealloyi ezithile ezikhethekileyo ukuze wenze ngokwemilo eyahlukileyo ngekhonkco elinemisonto okanye umbhobho womoya.

Uhluzo oluchaziweyo ngokobungakanani bokuhanjiswa kwepore.

Ukhetho lweMathiriyeli

I-HENGKO ifumaneka kuluhlu lwezinto.

Isisombululo sesinyithi somgubo senza uyilo lokuthunga kunye neemfunoiimfuno inkqubo ngamnye lula.

Imathiriyeli ekhoyo:

1. Intsimbi engatyiwa (standard 316L),

2. Hastelloy,

3. I-Innell,

4. IMoneli,

5. Ubhedu,

6. I-Titanium

7. I-Special Alloys xa uceliwe.

Usetyenziso

1. Ukuhluzwa kwegesi

Sinikezela ngeemveliso ezininzi kunye nezisombululo zokuhluza iigesi ezishushu kwizicelo zamashishini, kunye namaqondo obushushu okusebenza

idla ngokugqitha kuma-750°C ixesha elide. Ezi zihluzo zihlala zisebenza kwiinkqubo ezixhotyiswe ngokuzicoca ngokuzenzekelayo

izakhono, kunye nezinto zokucoca kufuneka zibe nako ukuhlaziya ngokupheleleyo kumjikelo ngamnye. ngokoizihluzi zesinyithi esinomgubo

lukhetho lungcono, kwaye zonke iimpawu zinokudibana; ngaloo ndlela, izihluzi zethu zokunyibilika ezinamaqhekeza zisetyenziswa ngokwandayo kwirhasi eninzi

amashishini okucoca.

2. Ukuhlambalaza

Uninzi lwezixhobo zoxinzelelo oluphezulu zifuna izinto zokucoca, ezinje ngonxibelelwano lwerhasi yolwelo olufunekayo ukusabela: ukuhluba, ukuxuba,

okanye ukusasazwa. Kwezinye izicelo ezininzi, siyakunceda ukwandisa ukusebenza kakuhle kwenkqubo ngokucebisa kunye nokuyila okona kulungileyo

isisombululo esifanelekileyo esisekelwe kwiintlobo ezininzi zeeyunithi ze-sparger ezikhoyo.

3. Ukucoca ulwelo

Sikwanikezela ngezinto eziyilwe ngokwesiko kunye nezizixhasayo zokucoca ukunyibilika ukuya kutsho kwisihluzo esisebenzayo se-0.1µm kulwelo. I

izihluzi zesinyithi esinomgubo we-sintered zingayilwa kunye nesandwich ezimbini, kunye namabakala amabini omgubo adityanisiweyo anikezelayo

Ukukhutshwa okuhambelanayo kunye nokulingana kunye nokuphucula ukuhamba xa kuthelekiswa nezihluzo eziyilwe ngokwesiqhelo. I sintered

I-porous disc sisihluzo esigqibeleleyo seenkqubo ezibandakanya i-catalyst. Izinto zethu zokucoca umgubo wentsimbi zine-a

ubomi obudlula uninzi lwezisombululo ezikhuphisanayo ngenxa yoyilo lwe-welding olunonxibelelwano "oluqilima-oluqilima".

4. Ulwelo

Sinikezela ukwenza ngokwezifiso izixhobo ze-fluidizing kwiinkqubo ezintsha kunye nesele zikhona ngokulawula ngokudinayo

Uyilo lwemveliso yokucoca ukuqinisekisa ukuhanjiswa kwerhasi okukuko okukhokelela ekuhambeni kobuninzi obugqibeleleyo okanye ukuxubana kwabaninzi

eendaba ezahlukeneyo, kuquka ubhedu, intsimbi engatyiwa, kunye nepolyethylene. Ukongeza, kuba fluidizing cones ezenziwe

izinto zetsimbi ezizinzileyo zidla ngokuzixhasa, sikholisa ukubonelela ngezihluzi ezineeflange ezidibanisayo

njengoko kufuneka.

Iqabane LETHU

Ukuza kuthi ga ngoku i-HENGKO inomsebenzi wewaka leenkampani ezivela kumashishini amaninzi abandakanya ikhemestry kunye neoyile, ukutya, unyango njl

Kwakhona iilebhu ezininzi zeenkampani kunye neyunivesithi kumthengisi wexesha elide weqabane. Ndiyathemba ukuba uya kuba ngomnye wabo,

qhagamshelana nathi namhlanje ukuba unomdla.

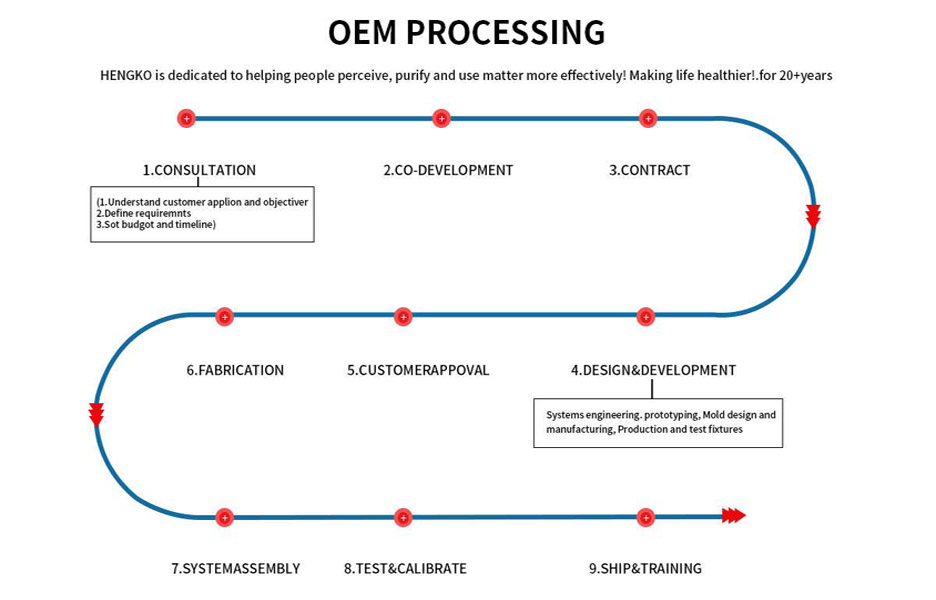

Uzenza njani izihluzi zesinyithi ze-Sintered Powder ezivela kwi-HENGKO

Xa unazoUyilo oluKhethekileyo lweSintered Melt Filterkwiiprojekthi zakho kwaye awukwazi ukufumana okufanayo okanye okufanayo Isihluzo

iimveliso, Wamkelekileukunxibelelana HENGKO ukusebenza kunye ukufumana esona sisombululo, kwaye nantsi inkqubo ye

OEM Porous Melt FilterNceda Yijonge kwayeQhagamshelana nathithetha iinkcukacha ezingakumbi.

I-HENGKO izinikele ekuncedeni abantu baqonde, basulungekise kwaye basebenzise uMba ngokuFanelekileyo! Ukwenza ubomi bube nempilo ngaphezu kweminyaka engama-20.

1.Uthethwano kunye noQhagamshelwano HENGKO

2.Co-Development

3.Yenza iSivumelwano

4.Uyilo noPhuhliso

5.Umthengi uvunyiwe

6. Ukwenziwa/Ukuveliswa kobuninzi

7. INdibano yeNkqubo

8. Vavanya kwaye ulinganise

9. Ukuhambisa ngenqanawe

Ngoko yintoni ishishini lakho? kwaye ingaba unayo nayiphi na imibuzo malunga nezihluzo zentsimbi kwaye ufuna ukuba sijongane okanye senze ngokwezifiso

izihluzi ezikhethekileyo zentsimbikwisixhobo sakho kunye nomatshini? Nceda uzive ukhululekile ukusithumelela umbuzo, Iqela lethu leR&D liyakwenza njalo

ukwazi ukukunika iimpendulo ezikhawulezayo nezanelisayo.

FAQ

1. Yintoni i-sintering in powder metallurgy?

I-Sintering isetyenziswa kwimetalurgy yomgubo ukuguqula umgubo wentsimbi ube yinto eyomeleleyo, enemingxuma. Le nkqubo ibandakanya

ukufudumeza i-powders yensimbi kwiqondo lokushisa elingaphantsi kwendawo yokunyibilika, okubangela ukuba amaqhekeza adibanise

kunye kwaye benze isakhiwo esiqinileyo.

Inkqubo ye-sintering iqhele ukusetyenziswa kwimveliso yentsimbi kunye nezixhobo, ezinje ngeebheringi, iigiya,

kunye nezihluzi. Inika iingenelo ezininzi kunezinye iindlela zokuvelisa, ezinje ngokuphosa okanye ukwenza, kubandakanywa

iindleko eziphantsi, ukuguquguquka okukhulu koyilo, kunye nokukwazi ukudala iimilo ezinzima kunye nezakhiwo.

Ngethuba lenkqubo ye-sintering, i-powders yensimbi ifakwe kwi-mold okanye i-fa, emisela ubume be

igqityiwe inxalenye. Emva koko umngundo ufakwa eziko, apho ufudunyezwa kubushushu obungaphantsi nje kokunyibilika

pioli yentsimbi. Njengoko i-powder zetsimbi zifudumala, ziqala ukudibanisa kunye nokwenza isakhiwo esiqinileyo.

Njengoko i-metal powders sinter, i-pores phakathi kwamaqhekeza iba yincinci kwaye incinci. Idala i-porous

imathiriyeli eyomeleleyo kwaye ehlala ixesha elide kodwa inommandla ophakamileyo, oyenza ilungele usetyenziso olunjalo

njengokucoca kunye nenkxaso ye-catalyst. Iyakwazi ukulawula ubungakanani kunye nokusabalalisa iipores ngokulungisa i-sintering

ubushushu kunye nexesha kunye nokubunjwa kwe powders zetsimbi.

Emva kokuba inkqubo ye-sintering igqityiwe, into eqinileyo, i-porous material iyasuswa kwi-mold kwaye ivunyelwe

kuhle. Inxalenye egqityiweyo emva koko inokwenziwa ngoomatshini okanye iqhutywe ukuze idale imilo kunye nobukhulu obufunekayo.

I-Sintering yinkqubo eguquguqukayo enokudala iindawo ezininzi zetsimbi kunye namacandelo. Inika iingenelo ezininzi,

kubandakanywa iindleko eziphantsi, ukuguquguquka koyilo, kunye nokukwazi ukudala iimilo ezinzima kunye nezakhiwo. Nje ngeziphumo,

i-sintering isetyenziswa kakhulu ekwenzeni iinxalenye zentsimbi kunye namacandelo kwimoto, i-aerospace, kunye

amashishini ezonyango.

2. Kutheni i-sintering ibalulekile kwi-powder metallurgy?

I-Sintering yinkqubo ebalulekileyo kwi-metallurgy yomgubo kuba idibanisa amaqhekeza kumgubo wesinyithi ukuya

yenza into eqinileyo, edibeneyo. Yenziwa ngokufudumeza umgubo kwiqondo lobushushu elingaphantsi kwendawo yokunyibilika.

ebangela ukuba amasuntswana adibane ngokusasazwa.

Sintering ibalulekile ngenxa yezizathu ezininzi:

1. Ivumela ukudala iindawo ezinemilo enzima enokuba nzima okanye akunakwenzeka ukuyivelisa

ngokusebenzisa ezinye iindlela zokuvelisa.

2. Ingasebenzisa ukuvelisa iinxalenye ezineempawu eziphuculweyo zoomatshini, njengamandla amakhulu

kunye nobunzima.

3. I-Sintering inokudala izinto ezinobungozi kunye ne-porosity elawulwayo, eluncedo kwizicelo

ezifana nezihluzi kunye ne-catalysts.

Inkqubo ye-sintering ibandakanya ukufudumeza umgubo kwiqondo lobushushu elingama-80-90%.

indawo yokunyibilika kwayo phantsi kweemeko zoxinzelelo oluphezulu kunye nomoya olawulwayo. Ibangela i

amasuntswana ukuba asasazeke omnye komnye, enze ubunzima obuqinileyo. Inkqubo ye-sintering inokulawulwa

ukuvelisa uluhlu olubanzi lwe-microstructures kunye neempawu zomatshini, kuxhomekeke kwisicelo esithile.

Enye yeenzuzo eziphambili ze-powder metallurgy kukuba ivumela ukudala iinxalenye ezinemilo enzima

kunye nokunyamezela okuchanekileyo. Kungenxa yokuba umgubo wesinyithi unokubunjwa kuyo nayiphi na imilo usebenzisa iindlela ezahlukeneyo,

njengokucofa kunye nokuntywila. Oku kuguquguquka kuvumela abavelisi ukuba bavelise iinxalenye ezinejometri enzima

kunye nemilinganiselo echanekileyo, engenakwenzeka ngezinye iindlela zokuvelisa.

Ukuqukumbela, i-sintering yinkqubo ebalulekileyo kwi-powder metallurgy kuba ivumela ukudala iindawo

ezinemilo entsonkothileyo, iipropathi eziphuculweyo zoomatshini, kunye ne-porosity elawulwayo. Linyathelo eliphambili kumgubo

inkqubo yesinyithi kwaye yenza ukuba abavelisi bavelise iindawo ezikumgangatho ophezulu kwizicelo ezahlukeneyo.

Ke ukuba usenayo nayiphi na imibuzo kwaye unomdla kwiSintered Powder Metal Filters, wamkelekile

qhagamshelana nathi nge-imeyileka@hengko.com kwaye ungathumela umbuzo ngokulandela ifomu yokubuza, siya kuyithumela

emva ngaphakathi 24-Iiyure.