HENGKO® High Purity Semiconductor Gas Filter

Izihluzi zoluhlu oluphezulu zokucoceka ziyilelwe ukuhluza iigesi ze-semiconductor.Le ndibano edibeneyo edibeneyo iya kuzisa i-0.003 micron particle incediswe ukugcinwa.

Izihluzi zoluhlu oluphezulu zokucoceka ziyilelwe ukuhluza iigesi ze-semiconductor.Le ndibano edibeneyo edibeneyo iya kuzisa i-0.003 micron particle incediswe ukugcinwa.

Izihluzi zegesi zeSemiconductor zibandakanya ngaphakathi kuyo yonke insimbi yolwakhiwo lwensimbi engenasici kubandakanywa i-cartridge yensimbi engenasici kunye nenkxaso yesakhiwo, i-316L yensimbi engenasici ye-electropolished welded izindlu kwi-semiconductor ebalulekileyo yenkqubo ye-gas applications.

Hlanza indibano yokugqibela nge-nickel ehluziweyo ukufezekisa ukucoceka kokuqala.

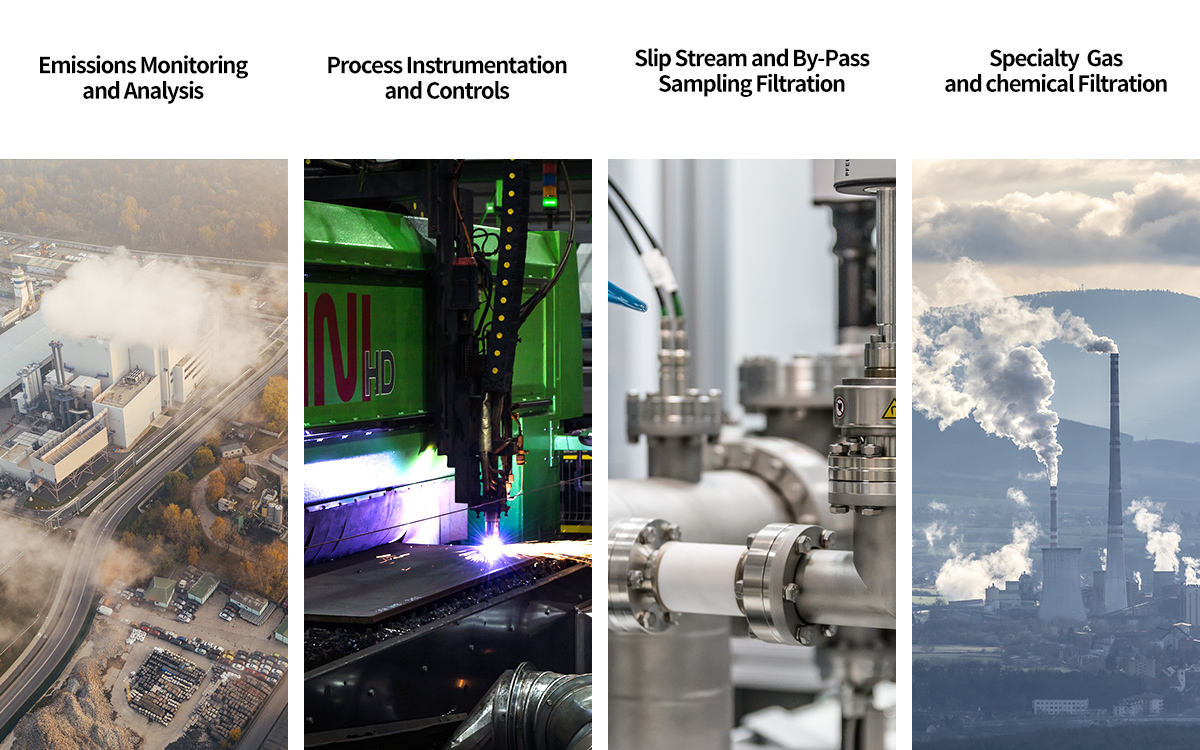

Amashishini ezicelo:

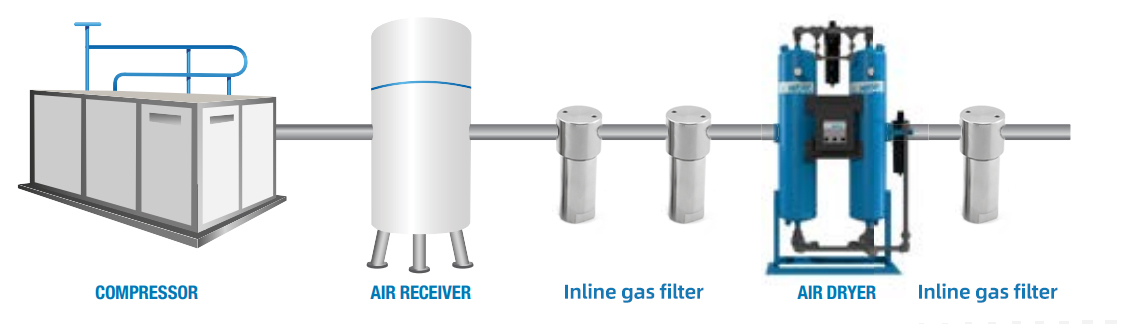

Indawo yokusetyenziswa kwe-semiconductor yokucoca igesi ekhethekileyo

I-inert kunye nokudluliselwa kwegesi ekhethekileyo.

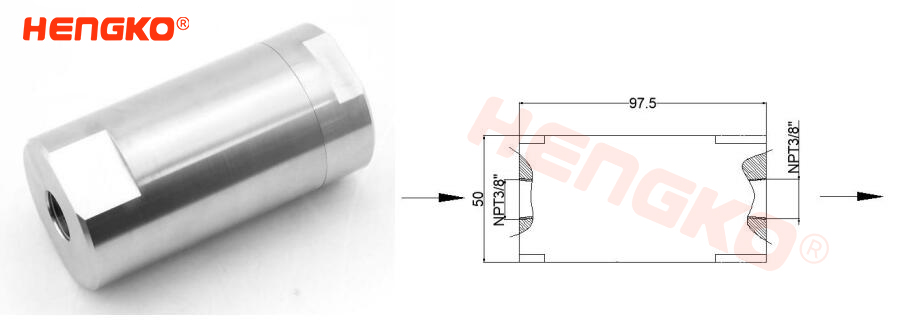

Iinkcukacha zobugcisa zezi zilandelayo:

3nm isihluzo sokulinganisa

Izihluzi zethu zensimbi ezingenasici zibonelela ngokusebenza kakuhle kogcino lwamasuntswana kwi-0.003μm.

Obona bushushu bokusebenza: 121°C (250°F)

Uxinzelelo oluphezulu lokusebenza: ibha ye-207 (3000 psig) kwi-20 ° C (68 ° F).

Iimpawu kunye neeNzuzo:

Imithombo yemithombo yeendaba yokucoca intsimbi erhabaxa / insimbi engenasici

I-316L izihlungi zetsimbi ezingenasici zibonelela ngokumelana nokuhamba okuphezulu kunye nokumelana neekhemikhali.

Umbane wezindlu ezingama-316L

Le ndibano yokucoca ine-10Ra ye-electropolished 316L yezindlu zensimbi ezingenasici ukukhusela ukubola kunye nokwakheka kwamasuntswana.

Ukuveliswa kwegumbi lokucoca

Izihluzi zethu zensimbi ezingenasici ze-semiconductor zegesi zenziwa kwigumbi elicocekileyo ukuqinisekisa ukuba i-particle-free, i-chemically clean, i-non-organic handling and bagging, inikezela umgangatho ophezulu wokucoceka ngaphandle kwengxowa.Unyango olongezelelweyo luyakhethwa.

FAQ

1. Yintoni isihluzo segesi ye-semiconductor yococeko oluphezulu?

Isihluzi segesi ye-semiconductor ecocekileyo luhlobo olukhethekileyo lwesihluzi esenzelwe ukususa ukungcola kwiigesi ezisetyenziselwa ukwenziwa kwezinto zombane.Ezi zihluzo zenziwe kwizinto ezinokumelana nokushisa okuphezulu kunye neekhemikhali ezitshabalalisayo, kwaye zenzelwe ukususa amaqhekeza ukuya kwinqanaba le-nano-scale.

2. Kutheni zibalulekile izihluzi zegesi ze-semiconductor ezicocekileyo?

Kwimveliso ye-semiconductors, kwanamanani amancinci okungcola angabangela iziphene kwaye anciphise umgangatho opheleleyo wemveliso yokugqibela.Izihluzi zegesi ze-semiconductor ezicocekileyo zinceda ekuqinisekiseni ukuba iigesi ezisetyenziswa kwiinkqubo zokuvelisa azikho kungcoliseko, okukhokelela kumgangatho ophezulu wezinto ze-elektroniki.

3. Ziziphi iintlobo zeegesi ezinokuhluzwa ngezihluzo zegesi ze-semiconductor ezicocekileyo?

Izihluzi zegesi ze-semiconductor ezicocekileyo zingasetyenziselwa ukuhluza uluhlu olubanzi lweegesi, kubandakanywa i-hydrogen, i-nitrogen, i-oksijini, kunye neentlobo zezinye iigesi zenkqubo.Ngokuxhomekeke kwinkqubo ethile yokuvelisa, iintlobo ezahlukeneyo zokucoca zingafunwa ukufezekisa inqanaba elifunwayo lokucoceka.

4. Zenziwa njani izihluzi zegesi ezicocekileyo zesemiconductor?

Izihluzi zegesi ze-semiconductor ezicocekileyo zenziwa kwizinto ezifana nensimbi engenasici, kunye nezinye iintsimbi eziphezulu.Izinto zokucoca ziqhelekile ukuba zincinci kakhulu, ezinobungakanani bepore ukusuka kwi-0.1 ukuya kwi-1 micron.Izihluzi zihlala zigqunywe ngezinto ezikhethekileyo zokuphucula iimpawu zazo zomphezulu kunye nokuphucula ukusebenza kwazo.

5. Zihlala ixesha elingakanani izihluzi zegesi ye-semiconductor yococeko oluphezulu?

Ubomi bokucoca igesi ye-semiconductor ephezulu bunokwahluka ngokuxhomekeke kwinani lezinto, kubandakanywa uhlobo lwesihluzo, igesi ehluzwayo, kunye nenkqubo ethile yokuvelisa.Ngokubanzi, ezi zihluzo ziyilelwe ukusetyenziswa ixesha elide kwaye zingahlala iinyanga ezininzi okanye iminyaka ngaphambi kokuba zifune ukutshintshwa.Ukugcinwa rhoqo kunye nokucoca kunokunceda ukwandisa ixesha lokuphila kwezi zihluzo kunye nokuqinisekisa ukusebenza okulungileyo ekuhambeni kwexesha.